Quick and precise elongation control method for temper mill

A technology of precise control and elongation rate, applied in the direction of elongation rate control, etc., can solve the problems of lack of fast real-time response characteristics and stable control methods, and achieve the effect of fast real-time response characteristics and strong system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

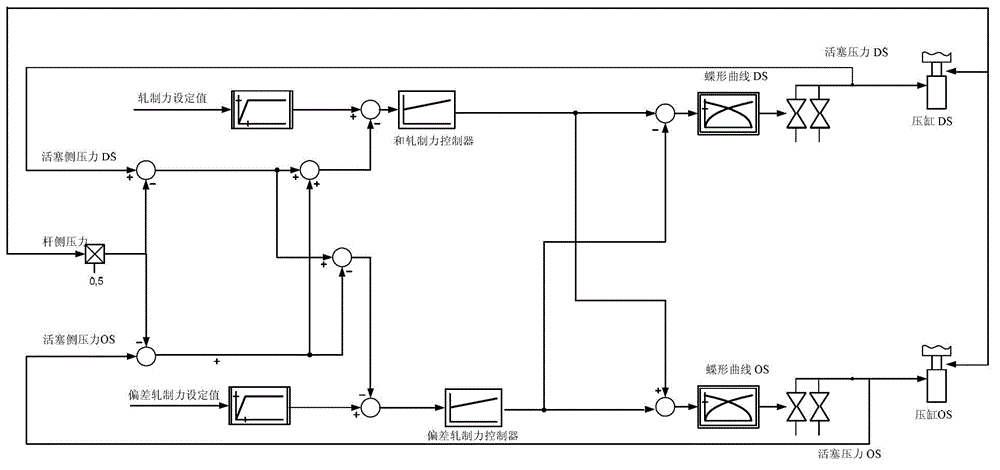

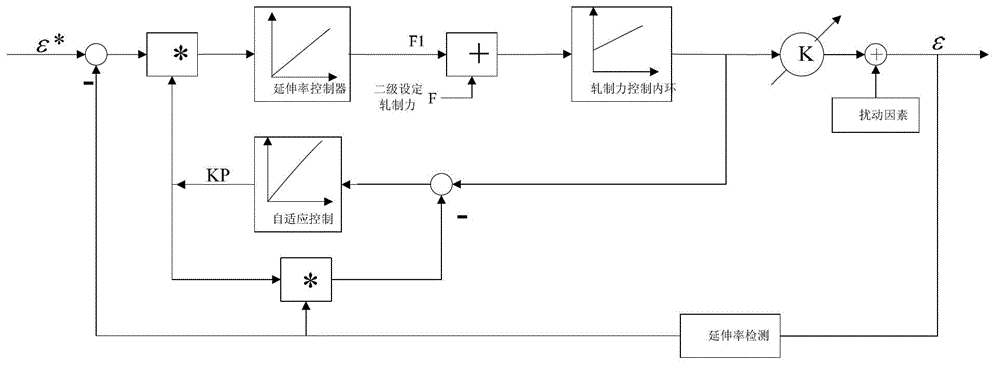

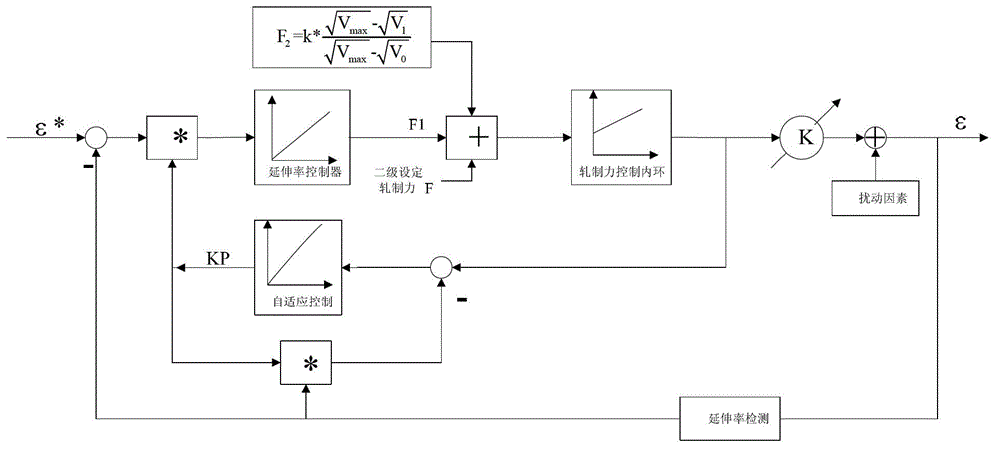

[0024] see Figure 1~3 , the specific steps are as follows:

[0025] Step 1. Design of the elongation control system of the temper mill, including the selection of controller software and hardware and the construction of the control system platform:

[0026] The control system hardware selects Siemens S7-400 series PLC and FM458 series high-speed closed-loop control module. S7-400 is selected for elongation control mode selection and start-stop logic, FM458 module is used as elongation controller, FM448 module is used for field bus data communication, and FM438 module is used for input and output signal processing. The elongation detection part adopts two methods of laser speedometer and encoder. The control software adopts Siemens STEP 7 V5.3 and D7 SYS system development environment.

[0027] Step 2. Elongation detection system of temper mill:

[0028] Two methods of laser velocimeter and encoder are used for actual elongation detection. The laser velocimeter is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com