Method for preparing polymer brush films with multiple stimulation responses

A multi-stimulus-responsive, polymer brush technology, applied in the homogeneous ATRP preparation of multi-stimulus-responsive polymer brush films, and the field of polymer brush film preparation, to achieve the effect of wide applicability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

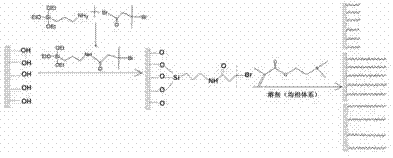

Method used

Image

Examples

Embodiment 1

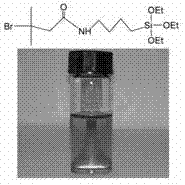

[0045] The synthesis of embodiment 1 initiator 4-(2-bromoisobutyramide) butyltriethoxysilane

[0046] Add 12.6 ml of 4-aminobutyltriethoxysilane to 50 ml of anhydrous tetrahydrofuran, and transfer it to an ice-water bath at 0°C, add 10 ml of 2-bromoisobutyryl bromide dropwise, and then add 15 ml The acid-binding agent triethylamine was maintained in an ice-water bath for 2 hours, and then the reaction was transferred to room temperature for 24 hours. After filtration, the filtrate was rotary evaporated to completely remove THF to obtain a yellow-brown product. The calculated yield was 85%. Fig. 2 is its solution appearance and infrared spectrogram.

Embodiment 2

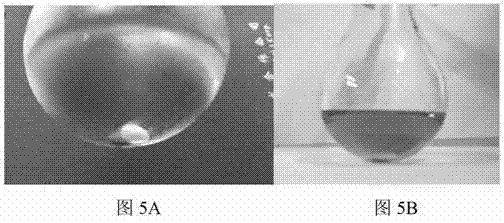

[0047] The synthesis of embodiment 2 initiator 3-(2-bromoisobutyramide) propyltriethoxysilane

[0048] Add 12.6 ml of 3-aminopropyltriethoxysilane to 50 ml of anhydrous tetrahydrofuran, and transfer it to an ice-water bath at 0°C, add 12.6 ml of 2-bromoisobutyryl bromide dropwise, and then add 14.3 ml Acid-binding agent triethylamine, after maintaining in an ice-water bath for 2 hours, transfer the reaction to room temperature and react for 24 hours. After filtration, the filtrate is rotary evaporated to remove tetrahydrofuran completely, and the yellow-brown product 3-(2-bromoisobutyramide) is obtained. Propyltriethoxysilane Initiator. Fig. 3 is its deuterated chloroform solution nuclear magnetic spectrum. NMR characterization: 1 H-NMR (CDCl 3 , 400MHz, TMS), δ: 6.89 (s, 1H, NH), 3.83 (q, 6H, J=6.8Hz, (CH 3 CH 2 O) 3 Si), 3.27 (q, 2H, J=6.8Hz, NCH 2 ), 1.95 (s, 6H, CH 3 C), 1.62~1.70 (m, 2H, CCH2), 1.23 (t, 9H, J=6.8Hz, (CH 3 CH 2 O) 3 Si), 0.65(t, 2H, J=8.4Hz, SiC...

Embodiment 3

[0050] The synthesis of embodiment 3 initiator 3-(2-bromoisobutyramide) propyltriethoxysilane

[0051] Except that the acid-binding agent was changed to pyridine, the same steps as in Example 2 were followed to obtain the tan product 3-(2-bromoisobutyramide)propyltriethoxysilane initiator. Fig. 3 is its deuterated chloroform solution nuclear magnetic spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com