Silicone rubber halogen-free wire/cable or sleeve, and preparation method thereof

A wire and cable, silicone rubber technology, applied in the direction of insulating cables, rubber insulators, cables, etc., can solve the problems of easy aging and reduced service life, and achieve the effects of fast vulcanization speed, increased yield and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

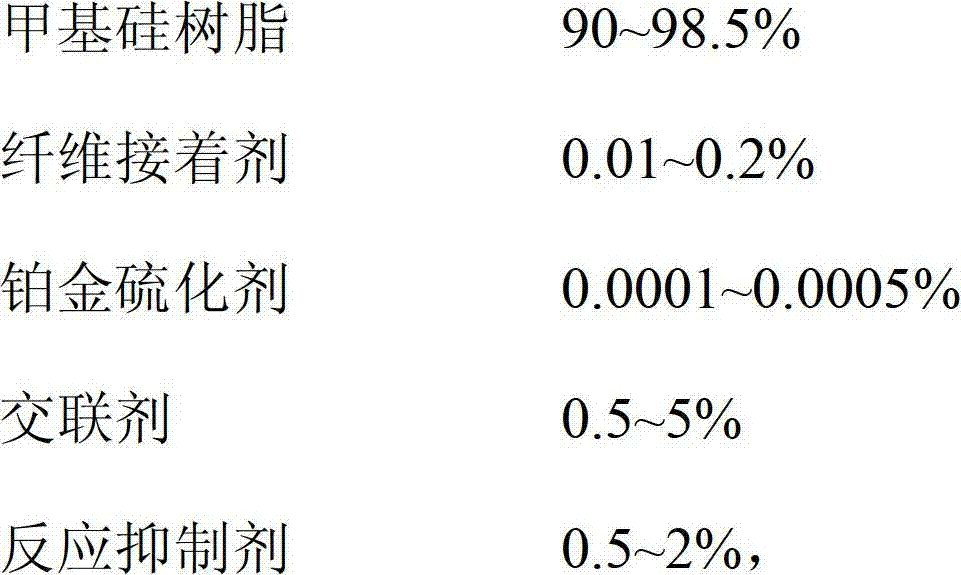

[0053] A kind of protective glue, comprising by weight fraction:

[0054]

[0055]

[0056] The components were mixed and kneaded, and vulcanized at 160° C. for 50 minutes to obtain the protective rubber.

[0057] A method for preparing silicone rubber halogen-free wire and cable or casing, comprising the steps of:

[0058] (1) Mixing: Mix a part of the silica gel raw material with the vulcanizing agent of Group A to obtain a mixed product; mix the remaining amount of silica gel raw material with the vulcanizing agent of Group B to obtain a mixed product, and mix the two parts of the mixed product After mixing, continue to knead to obtain the final kneading product; wherein, the mass ratio of the silica gel raw material to the A group vulcanizing agent is 500:1, the mass ratio of the silica gel raw material to the B group vulcanizing agent is 70:1, and the mixing temperature at 20°C;

[0059] (2) Extrude the mixed rubber obtained in step (1) at 20°C, the extrusion spee...

Embodiment 2

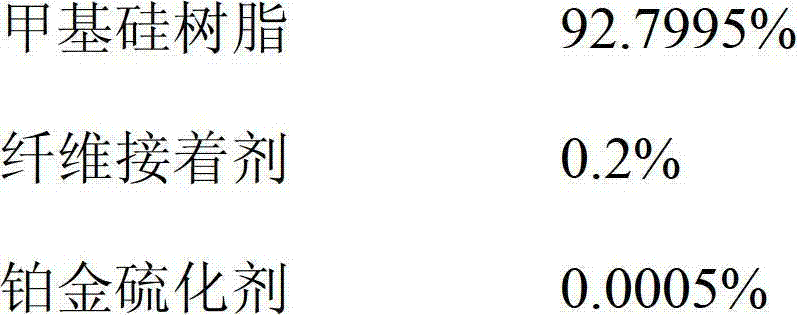

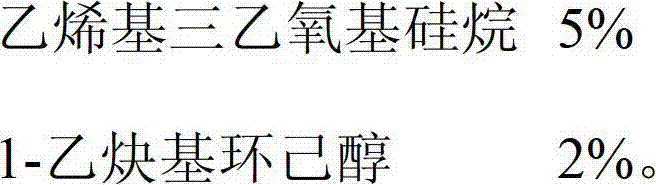

[0063] A kind of protective glue, comprising by weight fraction:

[0064]

[0065] The components were mixed and kneaded, and vulcanized at 240° C. for 15 minutes to obtain the protective rubber.

[0066] A method for preparing silicone rubber halogen-free wire and cable or casing, comprising the steps of:

[0067] (1) Mixing: Mix a part of the silica gel raw material with the vulcanizing agent of Group A to obtain a mixed product; mix the remaining amount of silica gel raw material with the vulcanizing agent of Group B to obtain a mixed product, and mix the two parts of the mixed product After mixing, continue to knead to obtain the final kneading product; wherein, the mass ratio of the silica gel raw material to the A group vulcanizing agent is 600:1, the mass ratio of the silica gel raw material to the B group vulcanizing agent is 60:1, and the mixing temperature 35°C;

[0068] (2) Extrude the mixed rubber obtained in step (1) at 35°C, the extrusion speed is 350 rpm, a...

Embodiment 3

[0072] A kind of protective glue, comprising by weight fraction:

[0073]

[0074] The components were mixed and kneaded, and vulcanized at 200° C. for 30 minutes to obtain the protective rubber.

[0075] A method for preparing silicone rubber halogen-free wire and cable or casing, comprising the steps of:

[0076] (1) Mixing: Mix a part of the silica gel raw material with the vulcanizing agent of Group A to obtain the mixed product; mix the remaining amount of the silica gel raw material with the vulcanizing agent of Group B to obtain the mixed product, and mix the two parts of the mixed product After mixing, continue kneading to obtain the final kneading product; wherein, the mass ratio of the silica gel raw material to the A group vulcanizing agent is 700:1, the mass ratio of the silica gel raw material to the B group vulcanizing agent is 50:1, and the mixing temperature 50°C;

[0077] (2) Extrude the mixed rubber obtained in step (1) at 50°C, the extrusion speed is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com