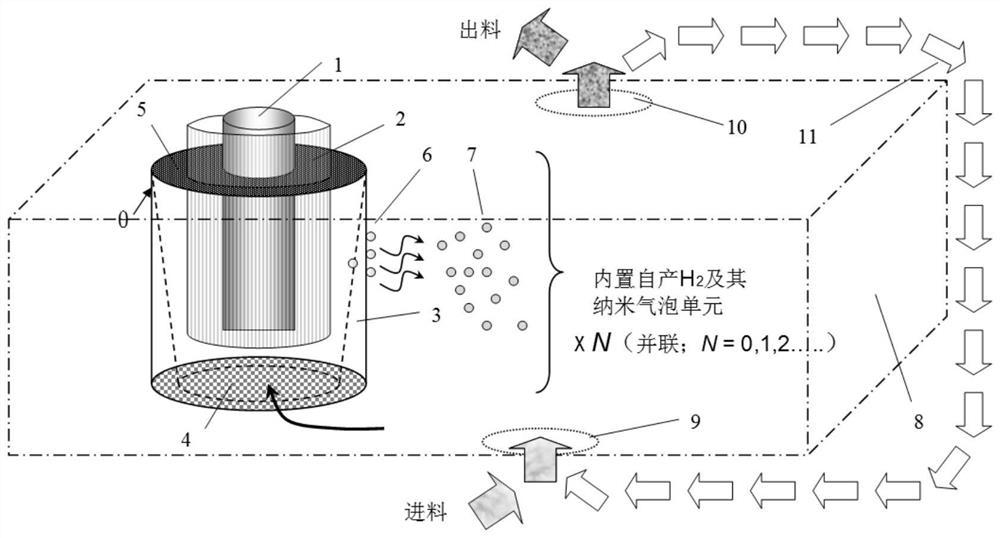

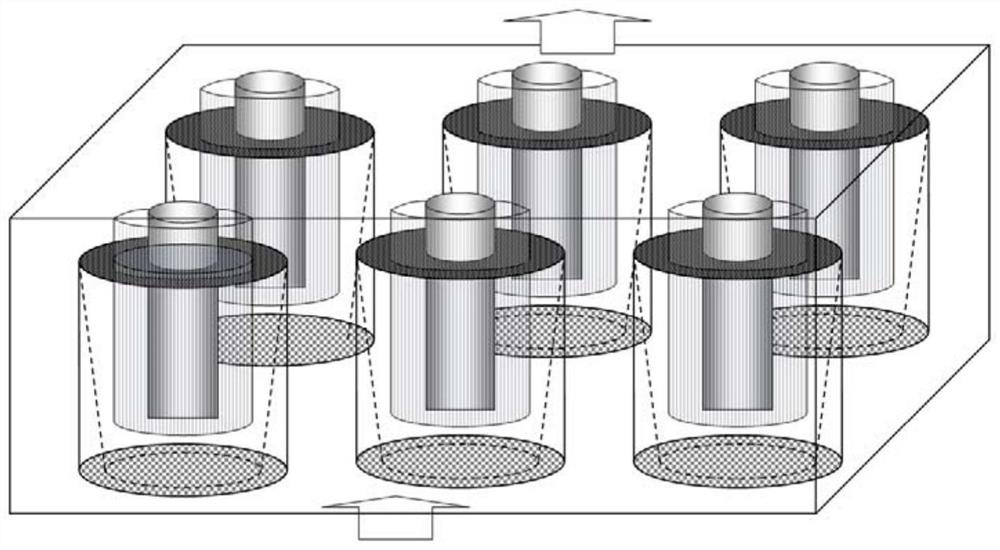

An Ultrasonic-Electrode-Nanoporous Membrane Coupling Hydrogen Production Sterilization System

A nanoporous, electrode technology, applied in the direction of electrode shape/type, dairy products, milk preparations, etc., to achieve the effect of promoting self-circulating microflow, rich taste, and high-efficiency products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

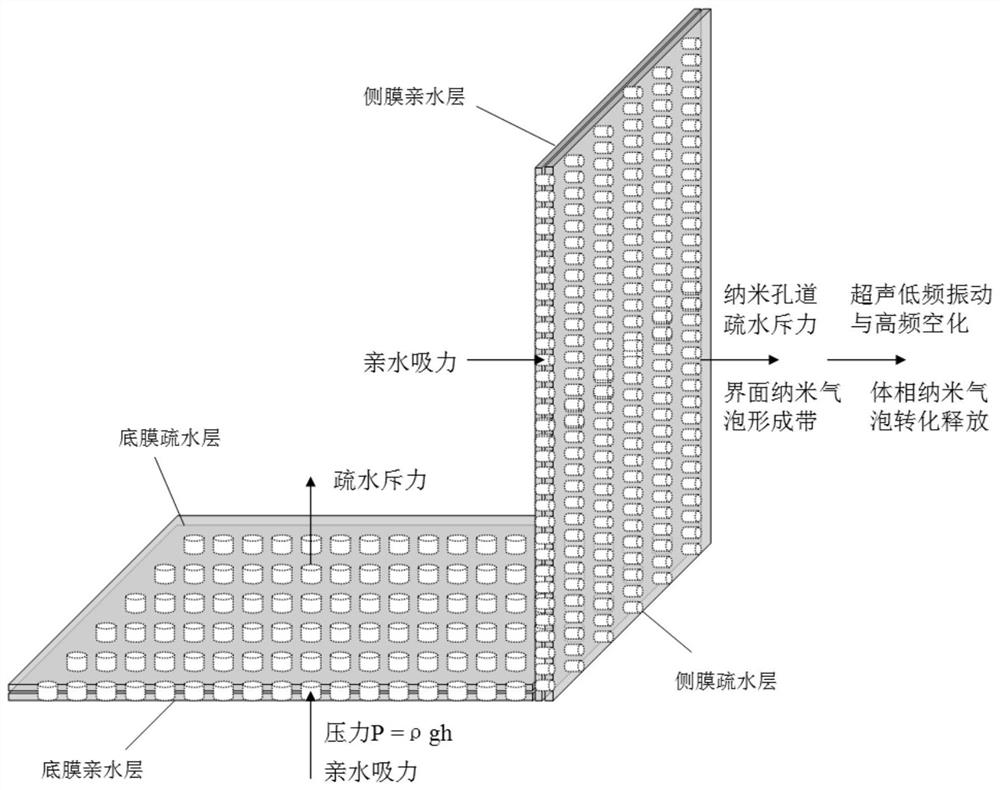

[0024] Pass pure water through the pipe port at the bottom of the container until it fills the entire reaction container and covers the hydrogen production unit. The liquid enters from the porous membrane at the bottom of the hydrogen production unit and reacts to generate hydrogen under the action of the ring electrode. At this time, the temperature is controlled at 0°C; When a large amount of hydrogen is enriched and passes through the nanoporous metal membrane on the side of the microreactor (aperture 200 nm; θ = 45°), the ring electrode is closed, and the broadband ultrasonic generator (20KHz low frequency 5 min; 400KHz high frequency 15 min) The liquid mixing system causes linear oscillation and cavitation effects, thereby forming interfacial hydrogen nanobubbles (~300 nm) and gradually transforming into bulk hydrogen nanobubbles (~50 nm); ultrasonic cavitation and the energy release of part of the bubble rupture and microjet flow The effect completes the rapid sterilizati...

Embodiment 2

[0026] Pass mineral water through the pipe port at the bottom of the container until it fills the entire reaction container and covers the hydrogen production unit. The liquid enters from the porous membrane at the bottom of the hydrogen production unit and reacts to generate hydrogen under the action of electrodes. At this time, the temperature is controlled at 5°C; When a large amount of hydrogen is enriched and passes through the nanoporous fiber membrane on the side of the microreactor (pore size 100 nm; θ = 30°), the electrodes are turned off, and the ultrasonic generator (50KHz low frequency for 3 min; 400KHz high frequency for 10 min) is controlled to treat the hydrogen liquid. The mixed system causes linear oscillation and cavitation effects, thereby forming interfacial hydrogen nanobubbles (~150 nm) and gradually transforming into bulk hydrogen nanobubbles (~20nm); ultrasonic cavitation and the energy release and microjet effect of part of the bubble rupture are complet...

Embodiment 3

[0028]Pass the juice through the pipe port at the bottom of the container until it fills the entire reaction container and covers the hydrogen production unit. The liquid enters from the porous membrane at the bottom of the hydrogen production unit and reacts to generate hydrogen under the action of electrodes. At this time, the temperature is controlled at 30°C; a large amount of hydrogen When enriching and passing through the nanoporous ceramic membrane on the side of the microreactor (aperture 1000 nm; θ = 15°), turn off the electrode and control the ultrasonic generator (20KHz low frequency for 5 min; 200KHz high frequency for 5 min) to the hydrogen-liquid mixed system Cause linear oscillation and cavitation effect, thereby forming interfacial hydrogen nanobubbles (~1000 nm) and gradually transforming into bulk hydrogen nanobubbles (~800nm); ultrasonic cavitation and energy release of part of the bubble rupture and microjet effect complete the pure For rapid sterilization o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com