Grass curtain preparation method

A technology of straw mats and straws, which is applied in the field of preparation of straw mats, can solve problems such as easy mold and insects, and achieve the effects of improving anti-corrosion, improving temperature resistance, and ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

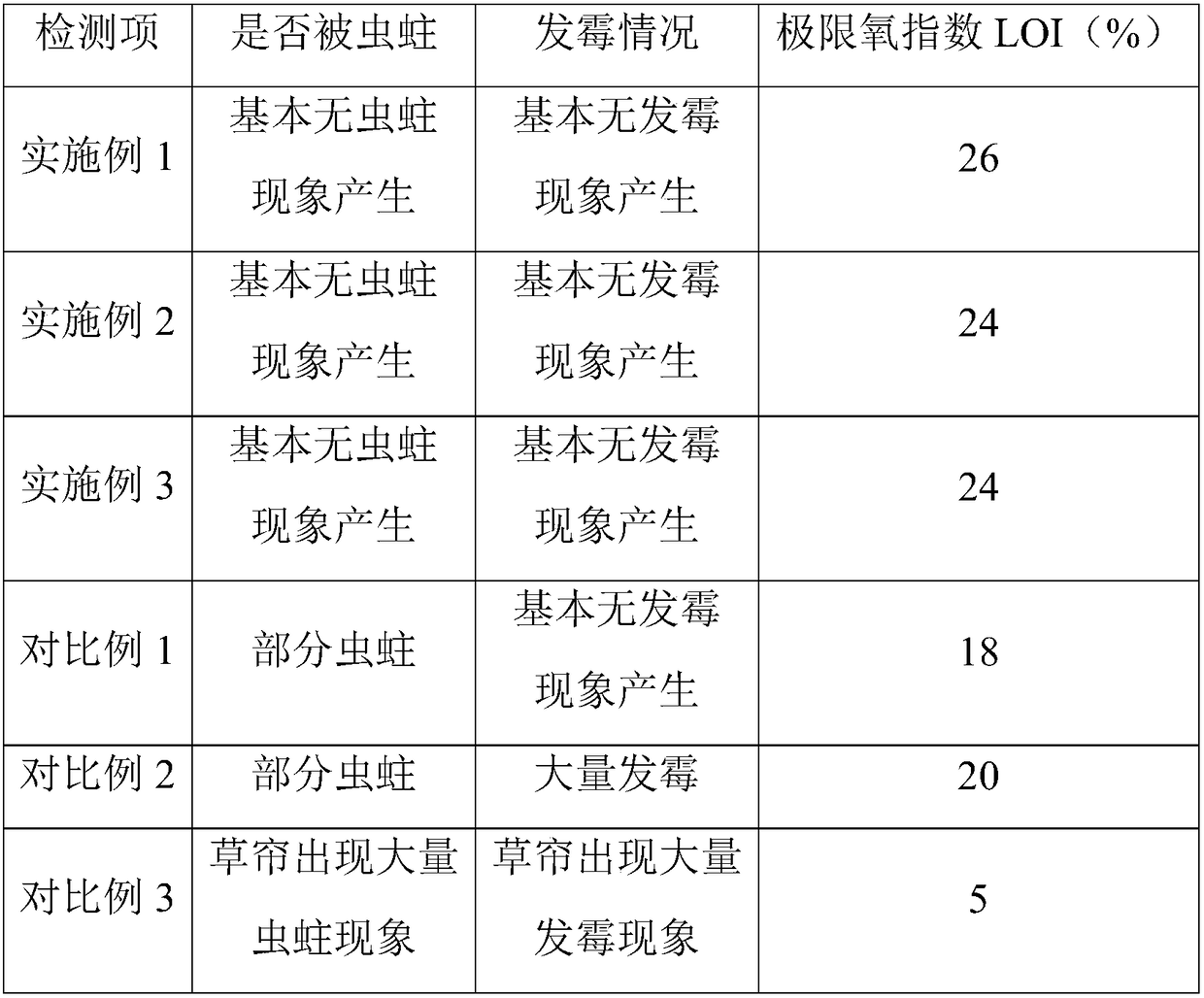

Embodiment 1

[0028] A kind of preparation method of straw curtain, is characterized in that, comprises the following steps:

[0029] (1) Place the straw under the conditions of 95°C and 340W, and ultrasonically treat it for 60 minutes;

[0030] (2) Put the ultrasonically treated rice straw in the culture solution, then add glycine-hydrochloric acid buffer solution, adjust the pH to 4.2, then add white rot fungus, and react for 40 hours at 20°C; wherein, the rice straw, culture solution The weight ratio with white rot fungus is 1:11:3;

[0031] The culture solution includes the following components by weight: 2 parts of yeast powder, vitamin B 1 0.4 parts, 1.5 parts of glucose, 1.5 parts of soluble starch, KH 2 PO 4 0.2 parts and MgSO 4 ·7H 2 O 0.5 parts

[0032] (3) Soak the straw treated in step (2) in the mixed solution for 8 hours, then add aluminum hydroxide, and continue soaking for 5 hours; the weight ratio of the straw, mixed solution and aluminum hydroxide is 0.5:8:0.08 ; ...

Embodiment 2

[0037] A kind of preparation method of straw curtain, is characterized in that, comprises the following steps:

[0038] (1) Place the straw under the conditions of 80°C and 200W, and ultrasonically treat it for 30 minutes;

[0039] (2) Place the ultrasonically treated rice straw in the culture solution, then add glycine-hydrochloric acid buffer to adjust the pH to 5, then add white rot fungi, and react at 30°C for 36 hours; wherein, the rice straw, culture solution The weight ratio with white rot fungus is 1:8:3;

[0040] The culture solution includes the following components by weight: 2 parts of yeast powder, vitamin B 1 0.4 parts, 1.5 parts of glucose, 1.5 parts of soluble starch, KH 2 PO 4 0.2 parts and MgSO 4 ·7H 2 O 0.5 parts

[0041] (3) Soak the straw treated in step (2) in the mixed solution for 10 hours, then add aluminum hydroxide, and continue soaking for 2 hours; the weight ratio of the straw, mixed solution and aluminum hydroxide is 2:10:0.15 ; The mixed...

Embodiment 3

[0046] A kind of preparation method of straw curtain, is characterized in that, comprises the following steps:

[0047] (1) Place the straw under the conditions of 100°C and 400W, and ultrasonically treat it for 60 minutes;

[0048] (2) Place the ultrasonically treated rice straw in the culture solution, then add glycine-hydrochloric acid buffer solution, adjust the pH to 5, then add white rot fungus, and react at 30°C for 50 hours; wherein, the rice straw, culture solution The weight ratio with white rot fungus is 5:11:5;

[0049] The culture solution includes the following components by weight: 2 parts of yeast powder, vitamin B 1 0.4 parts, 1.5 parts of glucose, 1.5 parts of soluble starch, KH 2 PO 4 0.2 parts and MgSO 4 ·7H 2 O 0.5 parts

[0050] (3) Soak the straw treated in step (2) in the mixed solution for 8 hours, then add aluminum hydroxide, and continue soaking for 5 hours; the weight ratio of the straw, mixed solution and aluminum hydroxide is 2:9:0.1 ; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com