Food-grade polyamide composite and preparation method thereof

A composite material, food-grade technology, applied in the polymer field, can solve the problems of the difference in the horizontal and vertical shrinkage of the composite material, unfavorable assembly of finished parts, low thermal deformation temperature, etc., to achieve good rigidity and toughness, good flow performance, high impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

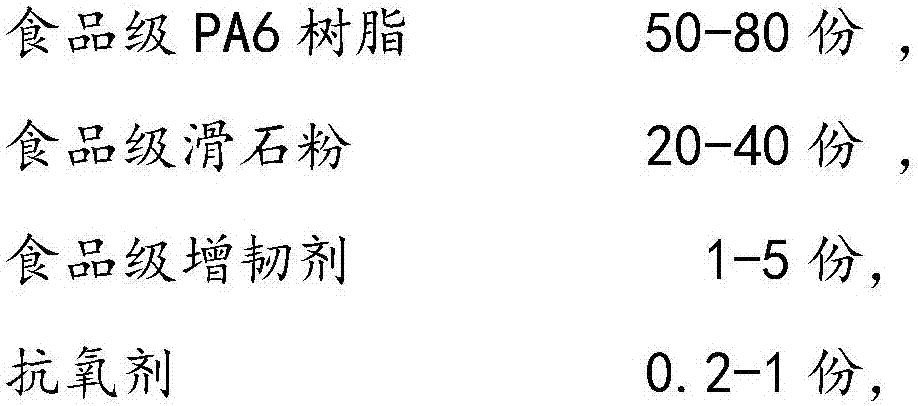

[0025] A food-grade polyamide composite material is prepared by the following components by weight:

[0026]

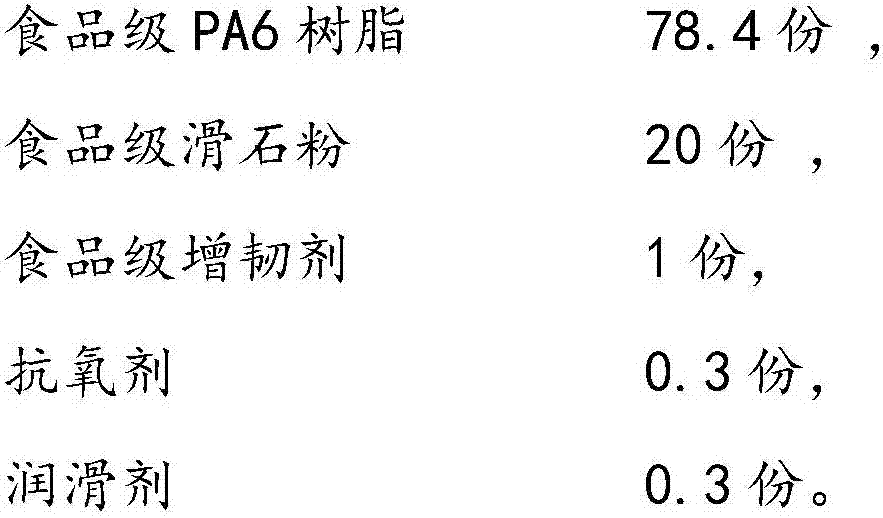

[0027] A preparation method of a food-grade polyamide composite material specifically includes the following steps:

[0028] (1), weigh 78.4 parts of food-grade polyamide, 20 parts of food-grade talcum powder, 1 part of food-grade toughening agent, 0.1 part of β-(3,5-di-tert-butyl-4-hydroxybenzene base) octadecyl propionate (antioxidant 1076), 0.2 parts of tris[2.4-di-tert-butylphenyl] phosphite (antioxidant 168) and 0.3 parts of modified ethylene bis stearamide and Add together to the mixer and mix at high speed for 2 minutes;

[0029] (2), put the mixed material obtained in step (1) into a parallel twin-screw extruder to melt, and after being extruded, enter a high-gloss mold and sequentially undergo water cooling, traction, and pelletizing to obtain a food-grade polyamide composite material; The barrel temperature of the extruder is 210-260°C, the screw speed ...

Embodiment 2

[0031] A food-grade polyamide composite material is prepared by the following components by weight:

[0032]

[0033] A preparation method of a food-grade polyamide composite material is the same as in Example 1.

Embodiment 3

[0035] A food-grade polyamide composite material is prepared by the following components by weight:

[0036]

[0037] A preparation method of a food-grade polyamide composite material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com