Asphaltene deposit dispersant

A dispersant and asphaltene technology, which is applied in the field of asphaltene sediment dispersants, can solve the problems of limited asphaltene dissolving ability and changing dispersion effect, and achieve the effect of high dissolution rate and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

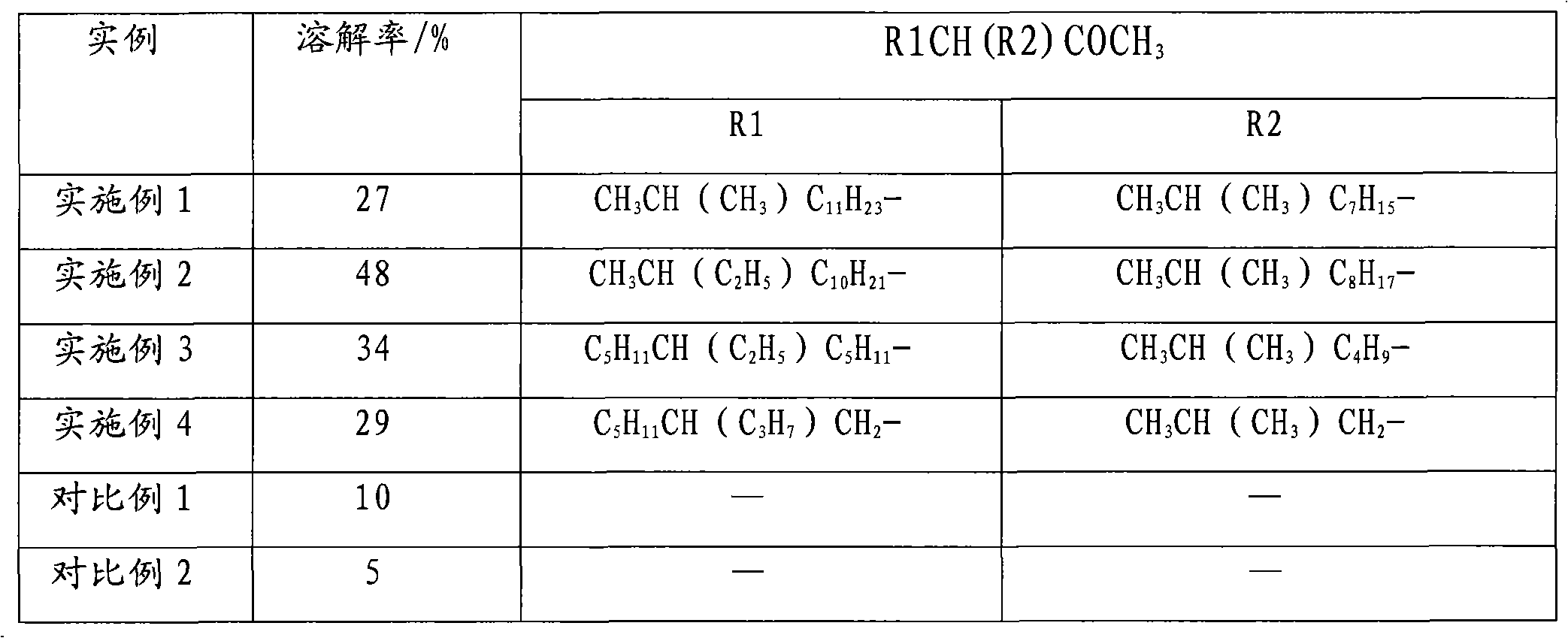

[0024] Weigh 0.05g of 2-nonylnaphthalenesulfonic acid and dissolve it evenly in 0.1g of n-pentane. Weigh 0.35g R1CH(R2)COCH 3 Dissolved in the above mixed solution to obtain asphaltene deposit dispersant. Weigh 10g of the asphaltene sediment from well TH10316 in Tahe, Xinjiang, mix it with the dissolving agent and dispersing agent evenly with magnetic stirring, and calculate the dissolution rate. The results are shown in Table 1.

Embodiment 2

[0026] Weigh 0.1 g of alkylnaphthalene with a molecular weight of 5000, and dissolve it in 0.5 g of cyclohexane evenly. Weigh 1.4g R1CH(R2)COCH 3 Dissolve in the above mixed solution to obtain asphaltene deposit dissolving agent dispersant. Weigh 10g of asphaltene deposits from Xinjiang Tahe TK614 heavy oil well, mix them with the dispersant evenly with magnetic stirring, and calculate the dissolution rate. The results are shown in Table 1.

Embodiment 3

[0028] Weigh 0.1g of polymethacrylate with a molecular weight of 2000, dissolve it evenly in 0.1g of straight-run kerosene, weigh 0.8g of R1CH(R2)COCH 3 Dissolve in the above mixed solution to obtain asphaltene deposit dissolving agent dispersant. Weigh 10g of the asphaltene sediment from well TH10316 in Tahe, Xinjiang, mix it with the dissolving agent and dispersing agent evenly with magnetic stirring, and calculate the dissolution rate. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com