Mixed liquid crystal material having high double-refractivity within terahertz frequency band

A large birefringence, terahertz technology, used in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high operating voltage, slow device response speed, modulation amount and transmittance decrease, etc., to achieve low viscosity, low working The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

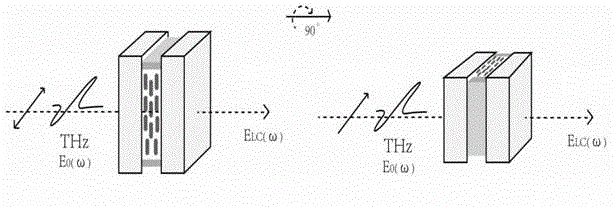

[0021] The thickness of the quartz used is 700 μm, the nominal value of the thickness of the polyester film is 125 μm, and the measured value of the high-resolution spectrometer is 126.8 μm, and a parallel orientation empty box is made.

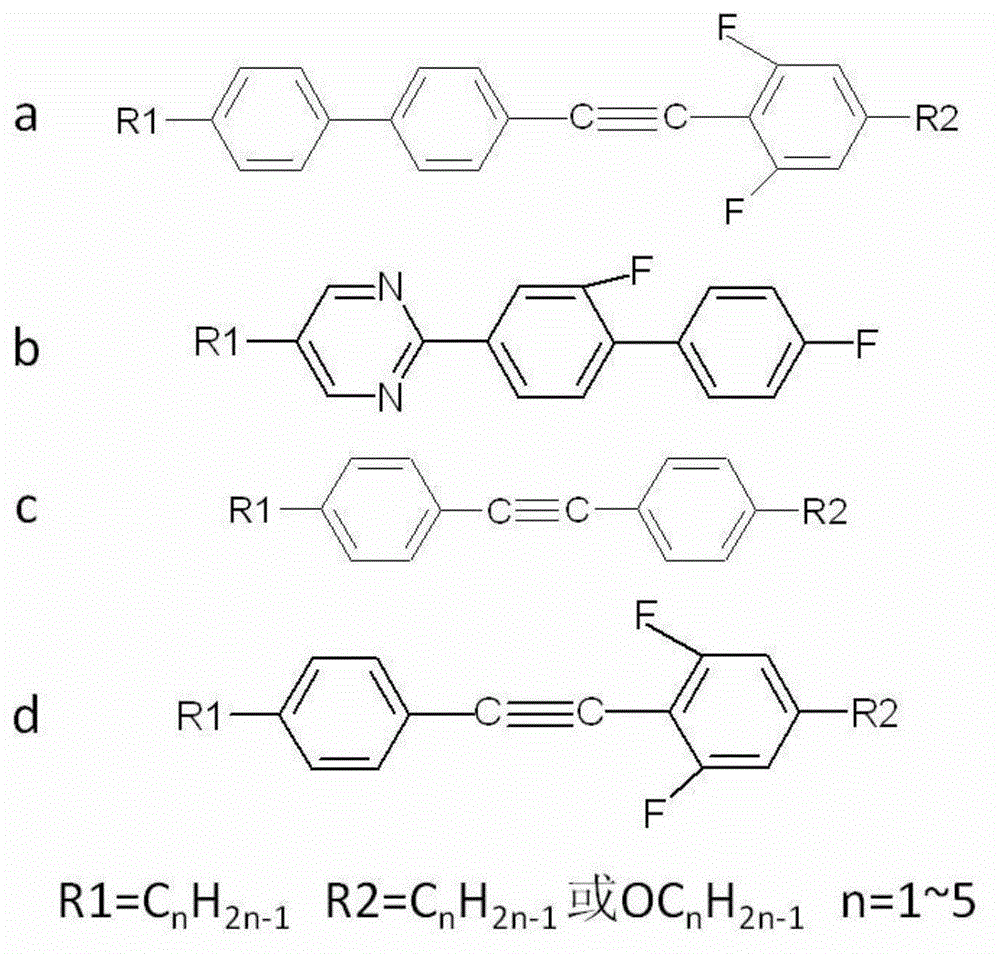

[0022] The mixed crystal material consists of 76% a component (a1: R1=C 2 h 5 , R2=C 3 h 7 10%; a2: R1=C 4 h 9 , R2=C 3 h 7 10%; a3: R1=C 3 h 7 , R2=C 2 h 5 10%; a4: R1=C 3 h 7 , R2=C 4 h 9 10%; a5: R1=C 2 h 5 , R2=OC 5 h 11 8%; a6: R1=C 3 h 7 , R2=OC 5 h 11 8%; a7: R1=C 3 h 7 , R2=OC 4 h 9 6%; a8: R1=C 2 h 5 , R2=OC 2 h 5 6%; a9: R1=C 3 h 7 , R2=OC 2 h 5 6%; a10: R1=C 3 h 7 , R2=OCH 3 2%), 12% b component (b1: R1=C 3 h 7 6%; b2: R1=C 5 h 11 6%), 5% c component (all R1=C 4 h 9 , R2=OC 2 h 5 ) and 7% of the d component (d1: R1 = C 3 h 7 , R2=C 2 h 5 4%; d2: R1=C 3 h 7 , R2=OCH 3 Accounting for 3%) melt mixing formation.

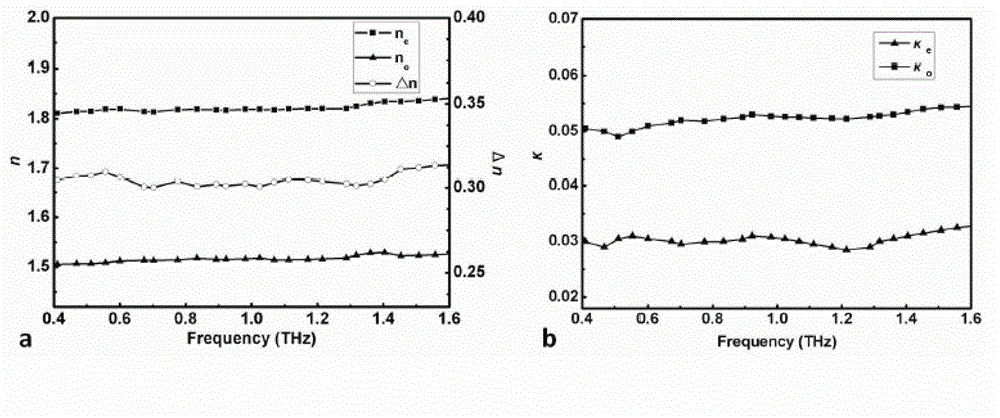

[0023] The physical properties of the actual test liquid crystal are as...

Embodiment 2

[0025] The thickness of the quartz used is 700 μm, the nominal value of the thickness of the polyester film is 125 μm, and the measured value of the high-resolution spectrometer is 126.8 μm, and a parallel orientation empty box is made.

[0026] The mixed crystal material consists of 81% a component (a1: R1=C 2 h 5 , R2=C 3 h 7 10%; a2: R1=C 4 h 9 , R2=C 3 h 7 10%; a3: R1=C 3 h 7 , R2=C 2 h 5 10%; a4: R1=C 3 h 7 , R2=C 4 h 9 10%; a5: R1=C 2 h 5 , R2=OC 5 h 11 10%; a6: R1=C 3 h 7 , R2=OC 5 h 11 10%; a7: R1=C 3 h 7 , R2=OC 4 h 9 7%; a8: R1=C 2 h 5 , R2=OC 2 h 5 6%; a9: R1=C 3 h 7 , R2=OC 2 h 5 6%; a10: R1=C 3 h 7 , R2=OCH 3 2%), 12% b component (b1: R1=C 3 h 7 6%; b2: R1=C 5 h 11 6%), 5% c component (all R1=C 4 h 9 , R2=OC 2 h 5 ) and 2% of the d component (all for R1=C 3 h 7 , R2=C 2 h 5 ) are formed by melt mixing.

[0027] The physical properties of the actual test liquid crystal are as follows: liquid crystal clearing point T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com