High-unwinding-tension spandex oil preparation

A technology of spandex oil agent and unwinding tension, which is applied in the field of spandex oil agent, can solve the problems of non-conformity and low unwinding tension, and achieve good isolation, uniform unwinding tension, and good antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

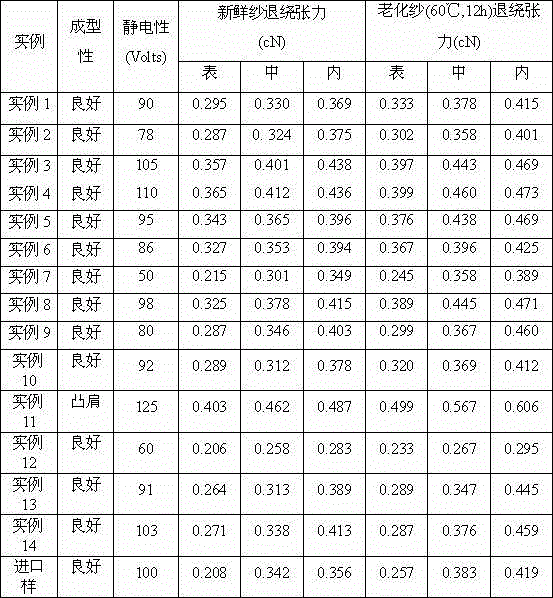

Examples

Embodiment 1

[0022] Add 80g of mineral oil (the kinematic viscosity at 25°C is 10 mm 2 / s), 5g of simethicone oil (kinematic viscosity at 25°C is 10 mm 2 / s) into a 250 mL flask, stirred for 5 min, and then added 13 g of isomeric cetyl alcohol, 1 g of phenyl-modified silicone oil (the kinematic viscosity at 25 °C is 100 mm 2 / s), 1g of isotridecanyl ether phosphate, fully stirred for 40min until the system is transparent and uniform, to obtain spandex oil.

Embodiment 2

[0024] Sequentially add 54g of mineral oil (the kinematic viscosity at 25°C is 10 mm 2 / s), 25g of simethicone oil (kinematic viscosity at 25°C is 10 mm 2 / s) into a 250 mL flask, stirred for 5 min, and then added 6 g of long-chain alkyl modified silicone oil (kinematic viscosity at 25 °C is 800-1000 mm 2 / s), 13g of isomeric stearyl alcohol, 2g of potassium lauryl phosphate, and fully stirred for 40min until the system was transparent and uniform to obtain spandex oil.

Embodiment 3

[0026] Sequentially add 74g of mineral oil (the kinematic viscosity at 25°C is 10 mm 2 / s), 10g of simethicone oil (the kinematic viscosity at 25°C is 10 mm 2 / s) into a 250 mL flask, stirred for 5 min, and then added 13 g of isomeric stearyl alcohol and 1 g of phenyl-modified silicone oil (the kinematic viscosity at 25 °C is 100 mm 2 / s), 1g of isotridecanyl ether phosphate, 1g of polyalphaolefin, fully stirred for 40min until the system is transparent and uniform, to obtain spandex oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com