Combined soil nailing construction method

A construction method and soil nailing technology, applied in excavation, infrastructure engineering, sheet pile walls, etc., can solve the problems of increased support displacement, difficulty under the steel bar, and inability to achieve reinforcement effects, so as to improve the pullout resistance and improve The grouting efficiency and the effect of avoiding the loss of mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the drawings.

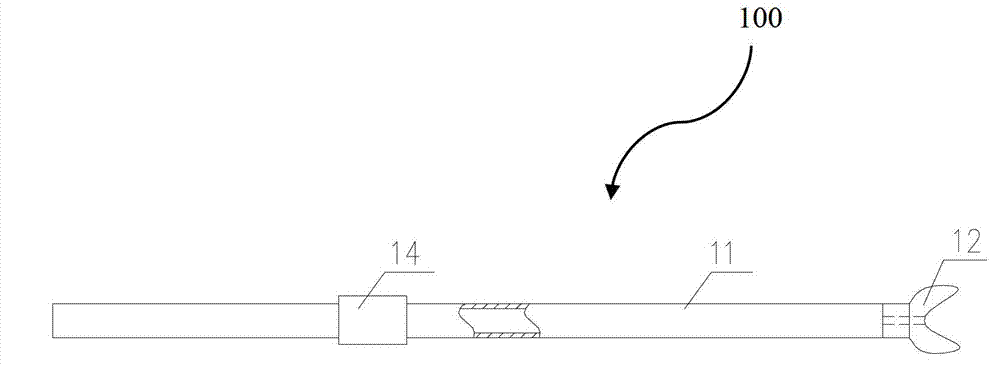

[0035] figure 1 A drilling tool 100 according to the present invention is shown, which includes a steel pipe 11 used as a drill rod and a drill bit 12 arranged at the front end of the steel pipe 11.

[0036] Preferably, a connecting sleeve 14 can be used to connect a plurality of steel pipes 11 according to actual conditions to achieve the required drilling depth. The drill bit 12 of the drilling tool 100 is made of a material with strong penetrating power, so that the drilling tool 100 can penetrate various soil layers.

[0037] In use, the drilling tool 100 uses the steel pipe 11 to drill holes on the slope. In one embodiment, the driving device used is a portable drilling machine, such as a hand-held coal power drilling machine. After drilling, the steel pipe 11 remains in the hole without being pulled out and is used as a grouting pipe in the grouting process described below. Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com