Method for detecting surface topography of aluminum electrode foil of electrolytic capacitor

A technology for electrolytic capacitors and aluminum electrode foils, applied in instruments, measuring devices, and using wave/particle radiation, etc., can solve the problems of not seeing the inner diameter of holes, difficult microscopic shape analysis, and inability to fully and accurately observe the microscopic shape of electrode foils, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

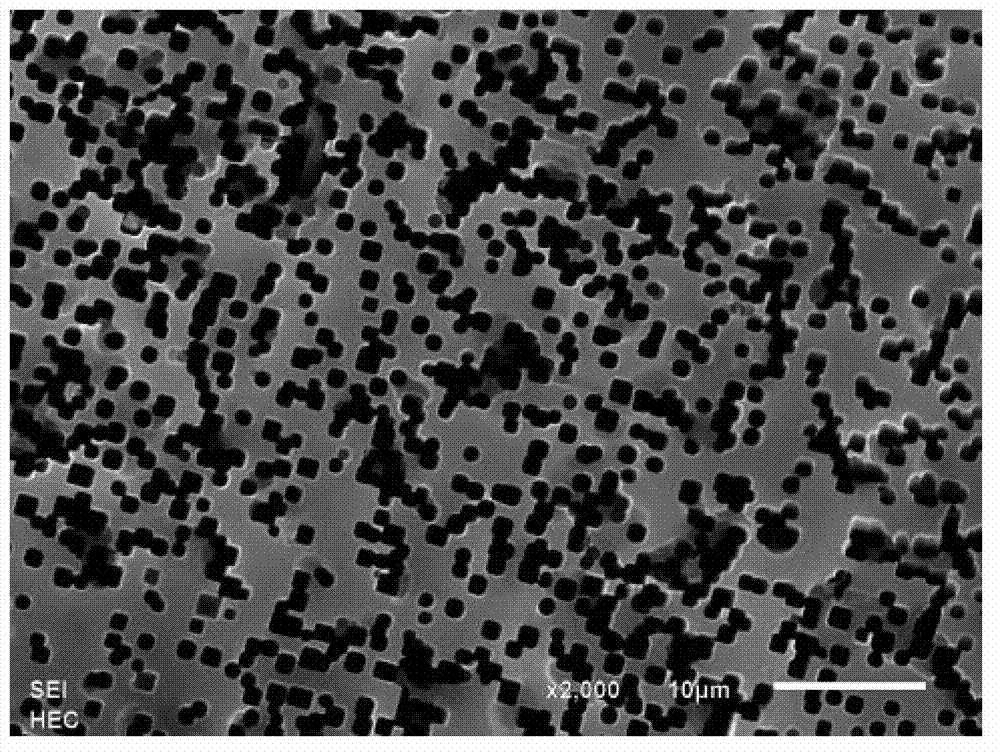

[0041] Such as Figure 4 , which is a schematic diagram of an electron micrograph of the surface of the formed foil of an aluminum electrolytic capacitor obtained in Example 1 of the method of the present invention. In this embodiment, the following operations are performed sequentially on the formed medium and high voltage electrode foils sampled from the formation production line:

[0042] a. Cut a 10mm*110mm sample from the aluminum electrode foil;

[0043] b. Coarse polishing: Use 400# water sandpaper dipped in water for rough polishing for 8 minutes;

[0044] c. Fine polishing: use 2000# water sandpaper dipped in water for fine polishing for 15 minutes;

[0045] d. Fine polishing: polishing with flannel cloth coated with 0.5um particle size diamond grinding paste, the time is 25 minutes;

[0046] e. Polishing with alkaline solution: wash the polished sample and soak it in an alkaline solution mixed with 5% sodium hydroxide and 7‰ sodium phosphate. The temperature condi...

Embodiment 2

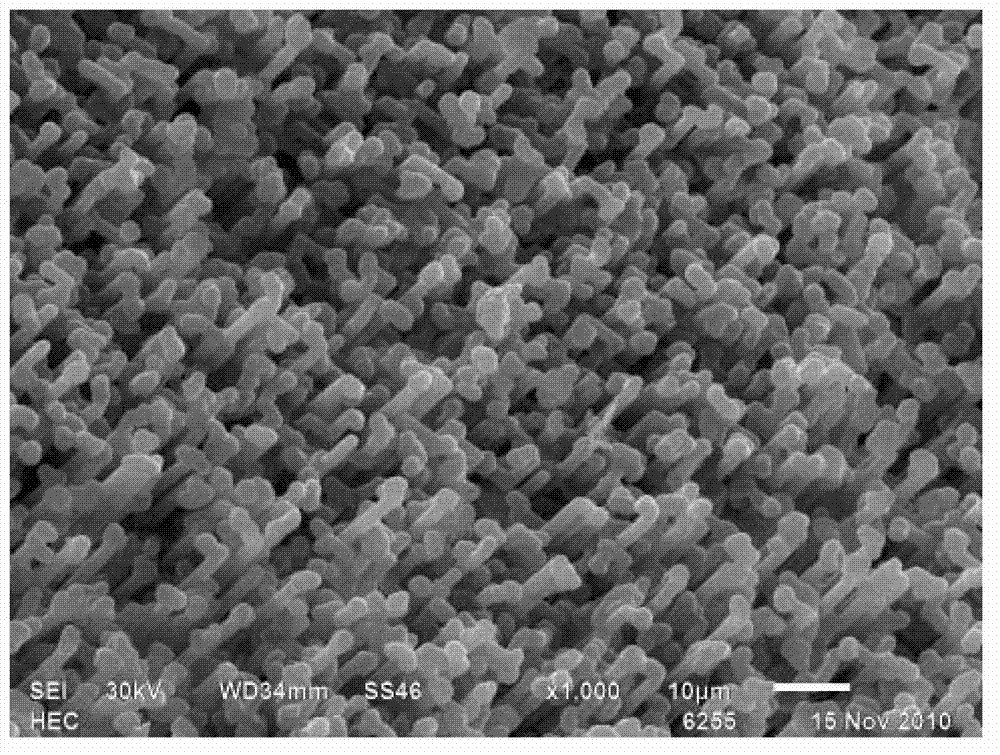

[0049] Such as Figure 5 , which is a schematic diagram of an electron micrograph of the surface of the formed foil of an aluminum electrolytic capacitor obtained in Example 2 of the method of the present invention. In this embodiment, the following operations are performed on the chemically formed medium and high voltage electrode foil produced by simulating the chemically formed production line:

[0050] a. Cut a 10mm*110mm sample from the aluminum electrode foil;

[0051] b. Coarse polishing: Use 400# water sandpaper dipped in water for rough polishing for 8 minutes;

[0052] c. Fine polishing: use 2000# water sandpaper dipped in water for fine polishing for 15 minutes;

[0053] d. Fine polishing: polishing with flannel cloth coated with 0.5um particle size diamond grinding paste, the time is 25 minutes;

[0054] e, electrolytic solution polishing, the electrolytic polishing solution is absolute ethanol: perchloric acid = 1: 4, and the current density is 0.1A / cm 2 , the...

Embodiment 3

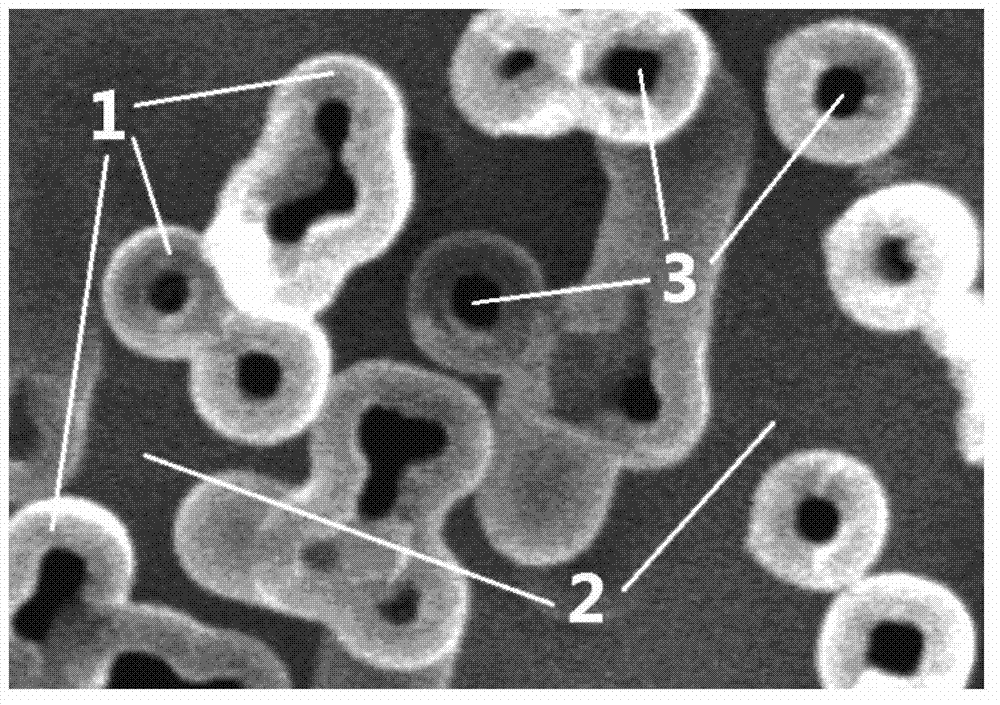

[0057] Such as Figure 6 , which is a schematic diagram of an electron micrograph of the surface of the chemically formed foil obtained in Example 3 of the method of the present invention. In this embodiment, the aluminum electrolytic capacitors produced by simulating the production line have been formed into medium and high voltage electrode foils, and the following operations are carried out:

[0058] a. Cut a 10mm*110mm sample from the aluminum electrode foil;

[0059] b. Coarse polishing: Use 400# water sandpaper dipped in water for rough polishing for 8 minutes;

[0060] c. Fine polishing: use 2000# water sandpaper dipped in water for fine polishing for 15 minutes;

[0061] d. Fine polishing: polishing with flannel cloth coated with 0.5um particle size diamond grinding paste, the time is 25 minutes;

[0062] e. Double solution polishing: firstly, the polished sample is washed and soaked in a mixed solution of 5% sodium hydroxide and 7‰ sodium phosphate alkaline solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com