Method for monitoring composite material engineering temperature

A composite material and engineering technology, applied in thermometers, thermometers with directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the problems of low precision and achieve the effects of preparing temperature measurement, improving sensitivity, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

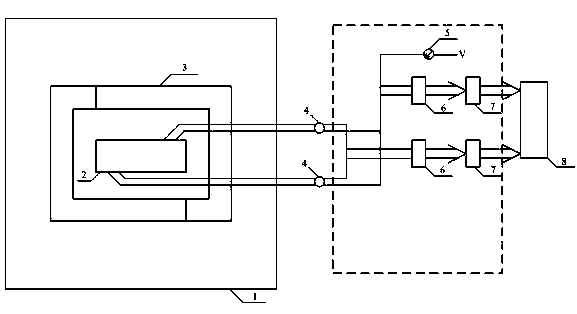

[0017] As shown in the figure, a composite material engineering temperature monitoring system includes a temperature sensor element 2, an L-shaped openable concrete structure 3 is arranged on the outside of the temperature sensor element, and the temperature sensor element is connected to a signal amplifier 6 through a wire 4, The signal amplifier 6 is connected to the data acquisition card 7 , the data acquisition card 7 is connected to the computer 8 , and the sensor element 2 is also connected to the constant voltage source 5 . When in use, the engineering temperature monitoring system is embedded in the large-volume concrete structure 1 where the temperature needs to be measured, and its voltage and current are connected to the signal amplifier 6 by using high-temperature resistant wires. The computer amplifies the voltage and current signals through the data acquisition card 7, and calculates And the calibration temperature-resistance conversion formula is used to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com