Tin-coated round copper wire

A technology of tinned round copper wire and copper wire, applied in the direction of rod/rod/wire/strip conductor, metal/alloy conductor, etc., can solve the problems of poor copper wire performance, achieve good electrical conductivity and mechanical properties, and protect the environment No pollution, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

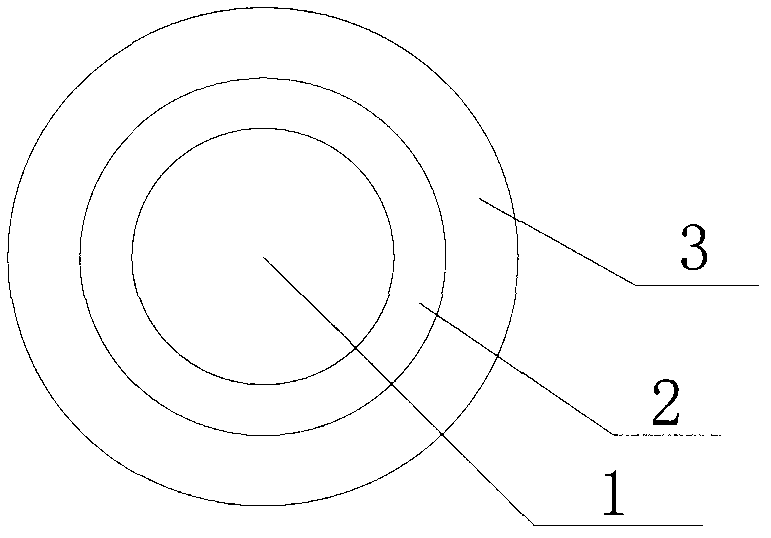

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] like figure 1 It is a structural schematic diagram of the present invention, a tinned round copper wire, including a copper wire 1 and a silver-plated layer 3 wrapped outside the copper wire 1 , and the copper wire 1 and the silver-plated layer 3 are provided with a tin-plated layer 2 . The tin-plated layer 2 ensures the oxidation resistance and good electrical conductivity of the present invention.

[0012] The tin-plated layer 2 is at least two layers. The performance of the copper wire is guaranteed by continuous tinning.

[0013] The production process of the copper wire is as follows: prepare the copper wire blank wire, and make soft copper wire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap