Stress sensitivity transformer iron core with protecting box and stress-free fixing method thereof

A transformer core, stress-sensitive technology, applied in the direction of transformer/inductor cores, etc., can solve the problems of magnetic performance loss, deformation internal stress, inability to apply high-conductivity magnet-based alloy stress-sensitive alloy cores, etc. Effects of elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

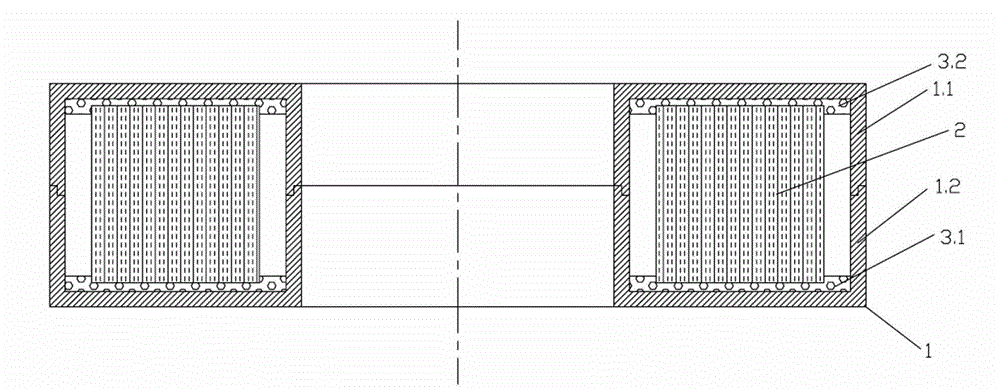

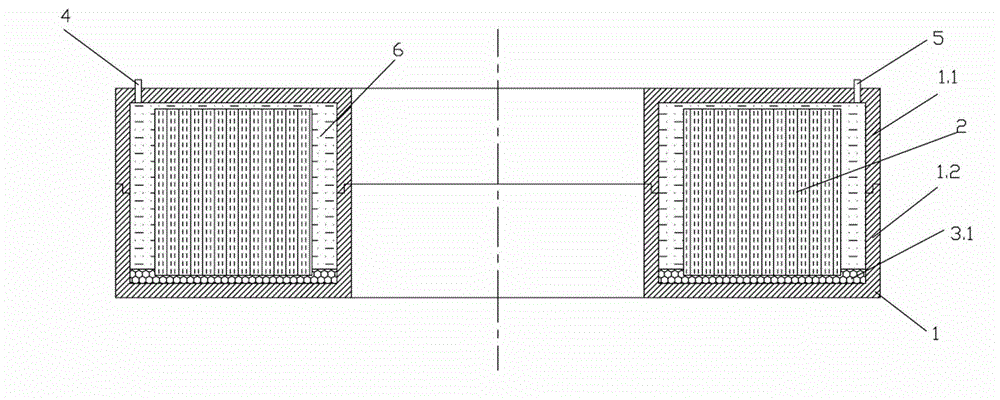

Embodiment 1

[0026] Such as figure 2As shown, the stress-sensitive transformer core with a protective box in this embodiment includes a protective box 1 and a stress-sensitive transformer core 2 inside the protective box 1, and the protective box 1 includes an upper half 1.1 and a lower half 1.2 , the upper surface of the upper part 1.1 is also provided with a symmetrical glue injection hole 4 and an air vent 5, both of which are connected to the inner cavity of the protective box 1, and the stress-sensitive transformer core 2 is wrapped in the stress-free glue 6 and is glued and connected with the stress-free glue.

[0027] The stress-sensitive transformer core with a protective box is prepared by the following method. The stress-free fixing method of the stress-sensitive transformer core in this embodiment is to place a thin sponge on the bottom of the inner cavity of the lower part 1.2 of the protective box 1 Pad 3.1, and then put the stress-sensitive transformer core 2 on it. The thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com