Degraded glass ceramic thin film for medical magnesium alloy surface and preparation method of degraded glass ceramic thin film

A glass-ceramic and magnesium alloy technology, applied in the fields of medical science, prosthesis, coating, etc., can solve the problem of not realizing the controllable degradation of magnesium alloy surface coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

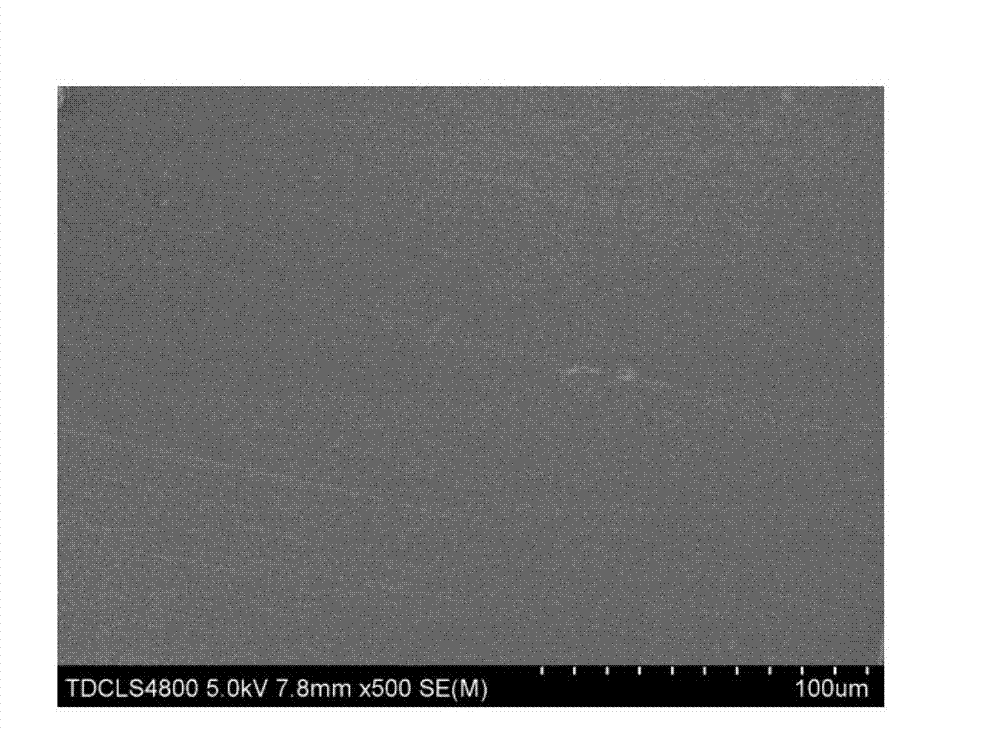

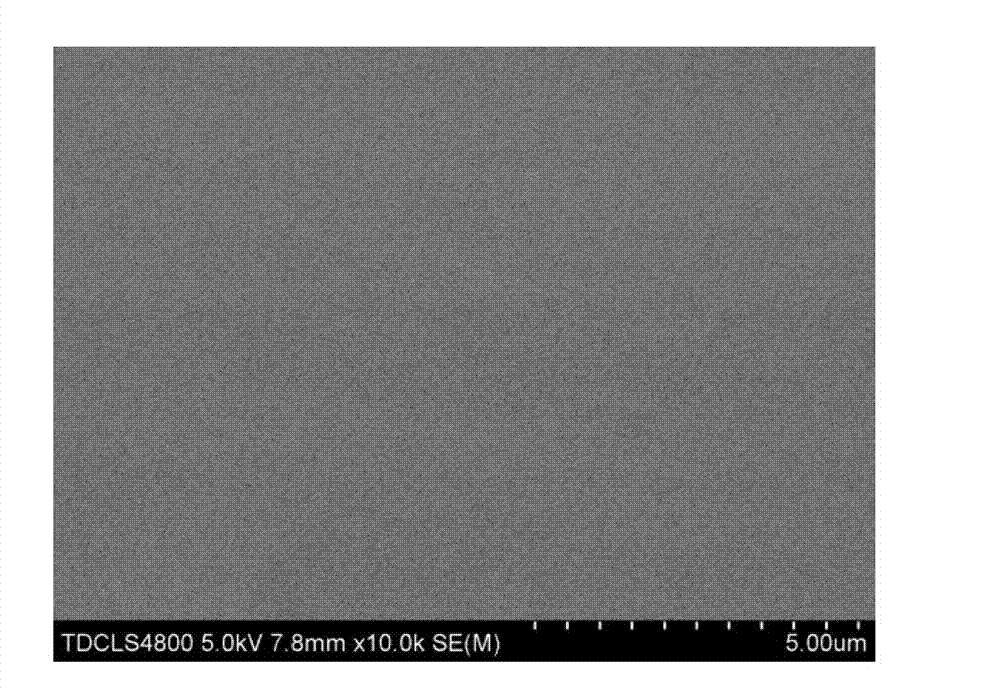

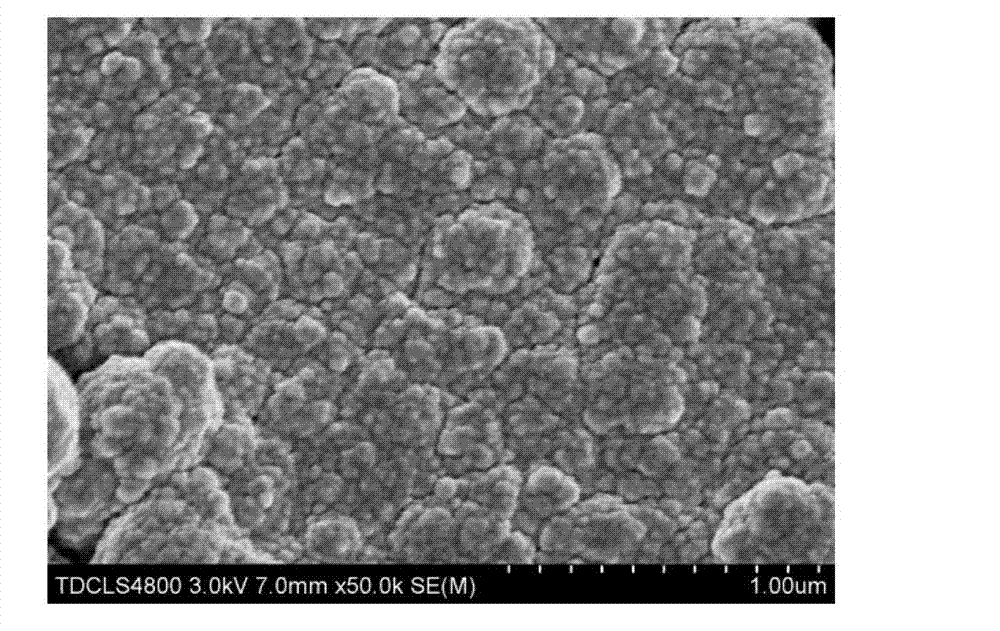

[0023] Example 1: CaO-P 2 o 5 -Na 2 O-ZnO glass ceramic film

[0024] with P 2 o 5 , Ca(NO 3 ) 2 4H 2 O, NaNO 3 , Zn(NO 3 ) 2 ·6H 2 O is raw material, press P 2 o 5 -CaO-Na 2 O mole percentage 47:47:6 accurately weighed 1.669 grams of P 2 o 5 , 2.773 g Ca(NO 3 ) 2 4H 2 O, 0.256 g NaNO 3 ;Press Zn(NO 3 ) 2 ·6H 2 O%=2mol% weighs 0.140 grams of Zn (NO 3 ) 2 ·6H 2 O.

[0025] (1) Preparation of P 2 o 5 Precursor solution: the weighed P 2 o 5 Slowly add 22.5ml of absolute ethanol and stir vigorously for 1~2h to form a stable transparent solution. Due to the violent reaction between phosphorus pentoxide and ethanol, a large amount of heat is released, so the P2 o 5 When adding to ethanol, it must be added slowly in a small amount, and it must be stirred quickly to release the heat quickly.

[0026] (2) Preparation of inorganic salt solution: Measure 10ml of ethylene glycol and 15ml of ethanol solution, and weigh the Ca(NO 3 ) 2 4H 2 O, NaNO 3 , Zn...

Embodiment 2

[0030] Example 2: CaO-P 2 o 5 -Na 2 O-SrO glass ceramic film

[0031] with P 2 o 5 , Ca(NO 3 ) 2 4H 2 O, NaNO 3 , Sr(NO 3 ) 2 For raw materials, press P 2 o 5 -CaO-Na 2 O mole percentage 47:47:6 accurately weighed 1.669 grams of P 2 o 5 , 2.773 g Ca(NO 3 ) 2 4H 2 O, 0.256 g NaNO 3 ; Press Sr(NO 3 ) 2 %=1~5mol% Weigh 0.050~0.249 grams of Sr(NO 3 ) 2 .

[0032] (1) Preparation of P 2 o 5 Precursor solution: the weighed P 2 o 5 Slowly add 22.5ml of absolute ethanol and stir vigorously for 1~2h to form a stable transparent solution. Due to the violent reaction between phosphorus pentoxide and ethanol, a large amount of heat is released, so the P 2 o 5 When adding to ethanol, it must be added slowly in a small amount, and it must be stirred quickly to release the heat quickly.

[0033] (2) Preparation of inorganic salt solution: Measure 10ml of ethylene glycol and 15ml of ethanol solution, and weigh the Ca(NO 3 ) 2 4H 2 O, NaNO 3 , Sr(NO 3 ) 2 Ad...

Embodiment 3

[0037] Example 3: CaO-P 2 o 5 -Na 2 O-MgO glass ceramic film

[0038] with P 2 o 5 , Ca(NO 3 ) 2 4H 2 O, NaNO 3 , Mg(NO 3 ) 2 ·6H 2 O is raw material, press P 2 o 5 -CaO-Na 2 O mole percentage 47:47:6 accurately weighed 1.669 grams of P 2 o 5 , 2.773 g Ca(NO 3 ) 2 4H 2 O, 0.256 g NaNO 3 ; Press Mg(NO 3 ) 2 ·6H 2 O%=1~3mol% Weigh 0.060~0.181 grams of Mg(NO 3 ) 2 ·6H 2 O.

[0039] (1) Preparation of P 2 o 5 Precursor solution: the weighed P 2 o 5 Slowly add 22.5ml of absolute ethanol and stir vigorously for 1~2h to form a stable transparent solution. Due to the violent reaction between phosphorus pentoxide and ethanol, a large amount of heat is released, so the P 2 o 5 When adding to ethanol, it must be added slowly in a small amount, and it must be stirred quickly to release the heat quickly.

[0040] (2) Preparation of inorganic salt solution: Measure 10ml of ethylene glycol and 15ml of ethanol solution, and weigh the Ca(NO 3 ) 2 4H 2 O, NaN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com