Manufacturing process of mobile phone built-in printed antenna

A technology of printed antennas and built-in antennas, applied in antenna supports/mounting devices, structural forms of radiation elements, etc., can solve problems such as reducing antenna gain and bandwidth, reduce antenna gain and bandwidth, reduce production costs, and improve price competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The manufacturing process of the mobile phone built-in printed antenna described in the application of the present invention is realized through the following technical solutions:

[0029] The process of the described built-in printed antenna comprises the following steps:

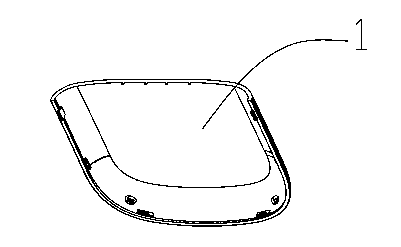

[0030] Step 1: If figure 1 As shown, the basic shape of the built-in antenna of the mobile phone is formed by injection molding. Its shape can be a separate antenna prototype, or it can be attached to the plastic shell or plastic mobile phone cover 1 of the mobile phone. The specific shape is finalized according to the actual design needs of the mobile phone;

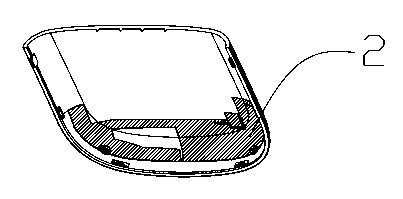

[0031] Step 2: If figure 2 As shown, the injection-molded antenna prototype is printed with a conductive ink layer 2 at a designated position on the plastic surface using a mobile printing process to prepare for the next step of electroplating copper film;

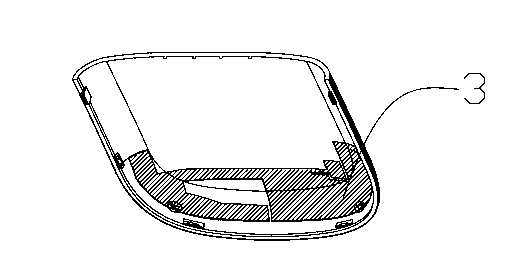

[0032] Step 3: If image 3 As shown, the printed antenna plastic prototype is el...

Embodiment 2

[0034] The process of the described built-in printed antenna comprises the following steps:

[0035] Step 1: If figure 1 As shown, the basic shape of the built-in antenna of the mobile phone is formed by injection molding. Its shape can be a separate antenna prototype, or it can be attached to the plastic shell or plastic mobile phone cover 1 of the mobile phone. The specific shape is finalized according to the actual design needs of the mobile phone;

[0036] Step 2: If figure 2 As shown, the injection-molded antenna prototype is printed with a conductive ink layer 2 at a designated position on the plastic surface using a mobile printing process to prepare for the next step of electroplating copper film;

[0037] Step 3: If image 3 As shown, the printed antenna plastic prototype is electroplated with the copper film layer 3 at the designated position on the plastic surface by electroplating process, so that it has the functions of conduction and signal reception;

[003...

Embodiment 3

[0040] Step 1: If figure 1 As shown, the basic shape of the built-in antenna of the mobile phone is formed by injection molding. Its shape can be a separate antenna prototype, or it can be attached to the plastic shell of the mobile phone or the plastic mobile phone cover 1. The specific shape is finalized according to the actual design needs of the mobile phone;

[0041] Step 2: If figure 2 As shown in the figure, the injection-molded antenna prototype is printed with a conductive ink layer 2 at a designated position on the plastic surface using a mobile printing process to prepare for the next step of electroplating copper film;

[0042] Step 3: If image 3 As shown, the printed antenna plastic prototype is electroplated with copper film layer 3 at the designated position on the plastic surface by electroplating process, so that it has the functions of conduction and signal reception;

[0043] Step 4: If Figure 5 As shown, the surface of the built-in antenna after elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com