Manufacturing method of roll mold for imprint

A manufacturing method and mold technology, which can be used in semiconductor/solid-state device manufacturing, anodizing, electrolytic coatings, etc., and can solve problems such as poor electricity supply and uneven surface temperature of roll-shaped aluminum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0334] A hollow cylindrical aluminum substrate (purity: 99.99%, length: 280mm, outer diameter: 200mm, inner diameter: 155mm) is subjected to fabric grinding treatment, followed by perchloric acid / ethanol mixed solution (volume ratio = 1 / 4) It is electrolytically polished.

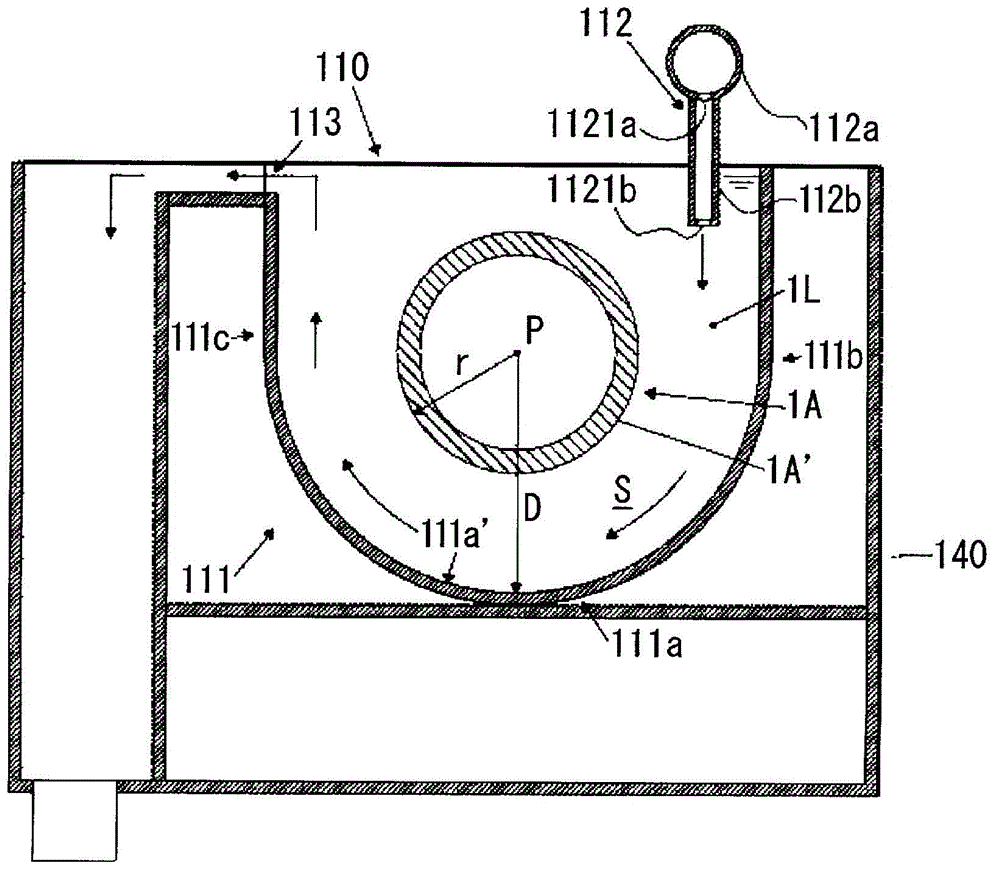

[0335] Next, use Figure 15 In the anodizing treatment device shown, in a 107L electrolyte solution composed of 0.3M oxalic acid aqueous solution, bath temperature: 15.7°C, DC: 40V, electrolyte supply rate: 41L / min, peripheral speed of the aluminum substrate: The aluminum substrate was anodized for 30 minutes under the condition of 3.8 m / min to form an oxide film (step (a)).

[0336] Temporarily dissolve and remove the formed oxide film in a mixed aqueous solution of 6% by mass phosphoric acid and 1.8% by mass of chromic acid (step (b)), and then perform anodic oxidation again under the same conditions as in step (a) for 45 seconds, An oxide film is formed (step (c)).

[0337] Thereafter, a pore-diameter...

Embodiment 2

[0360] In this example 2, for Figure 10 The illustrated anodizing treatment apparatus 210 is operated under specific conditions. The taper angle with respect to the axial direction of the two end faces of the hollow cylindrical aluminum substrate 220 (purity: 99.99%, length: 280 mm, outer diameter: 200 mm, inner diameter: 155 mm) and the end face of the current-carrying member 213 is set to 30°. , the surface roughness of each tapered surface 220A, 213A is set to Ra1.6.

[0361] In a 106L electrolyte solution composed of a 0.3mol / L aqueous solution, bath temperature: 15.7°C, electrolyte solution supply rate: 36L / min, pressing pressure of the two electrification members 213: 0.2MPa, circumference of the aluminum substrate 220 Under the condition of speed: 3.8m / min, and the condition of voltage: 40V, the aluminum substrate 220 was anodized for 60 minutes to form an oxide film.

[0362] exist Figure 12A In the figure, the experimental example (graph) which actually detected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com