Full-automatic fishskin peeler

A fish skinning machine, fully automatic technology, applied in the direction of fish skin removal, etc., can solve the problems of many rework, low product quality, poor efficiency, etc., and achieve the effect of safe operation, good skinning effect and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0019] The core of the present invention is to provide a fully automatic fish skinning machine, which has good peeling effect, high efficiency, low loss and safe operation.

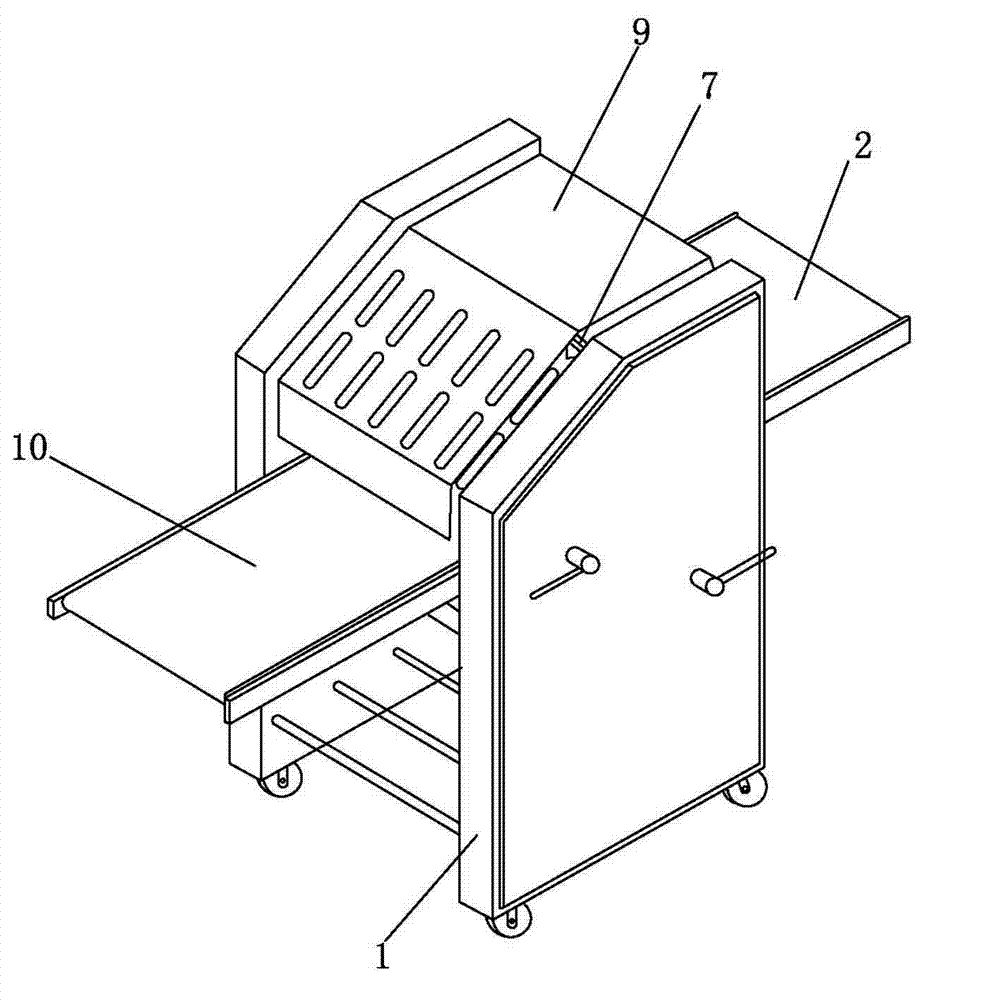

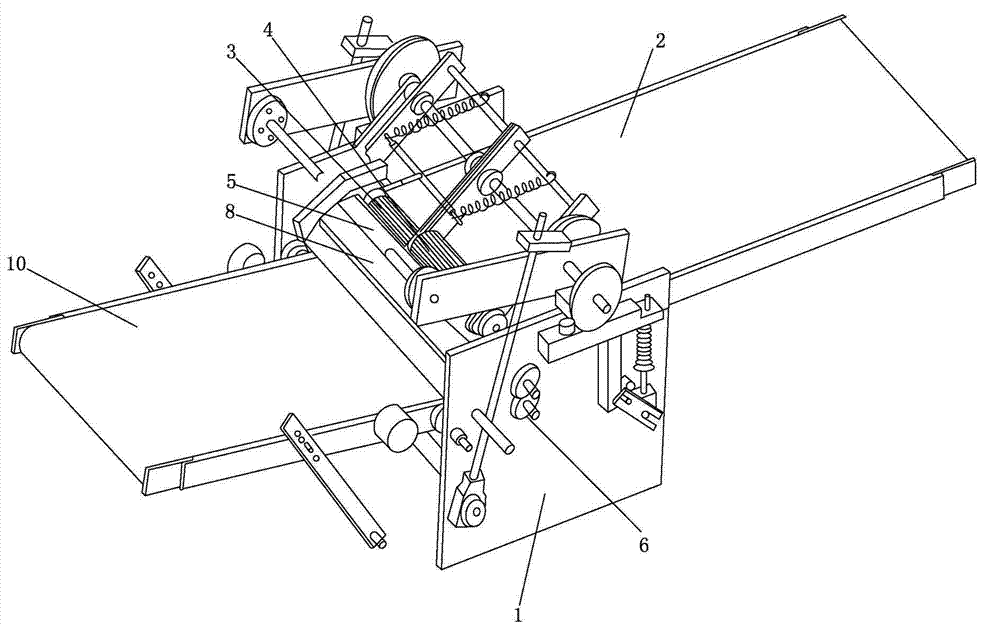

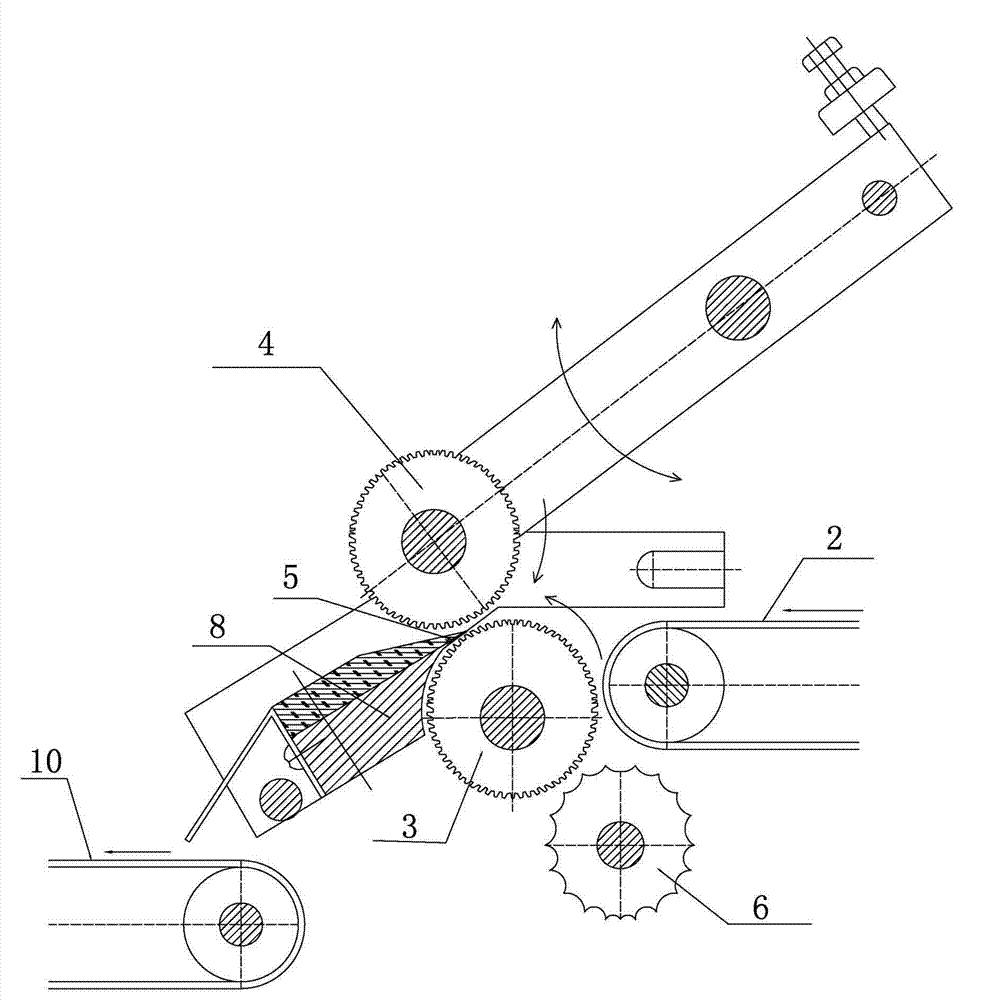

[0020] Such as figure 1 , figure 2 , image 3 As shown, the fully automatic fish skinning machine of the present invention includes a frame 1, and the frame 1 is provided with a feeding conveyor belt 2, a skinning roller 3, a pressure feeding roller 4, a skinning blade 5 and a power device (the power device is a deceleration motor, not shown in the figure, the power device drives all moving parts to move through multiple sets of sprocket transmission devices), and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com