Catalyst for synthesizing acidic gas absorbent and preparation method for catalyst

An acid gas and catalyst technology, which is applied in the field of catalyst for synthesizing acid gas absorbent and its preparation, can solve the problems of easy falling off of active components, decreased catalytic performance, many catalyst steps, etc., and achieves low price, simple preparation process, and avoidance of Easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

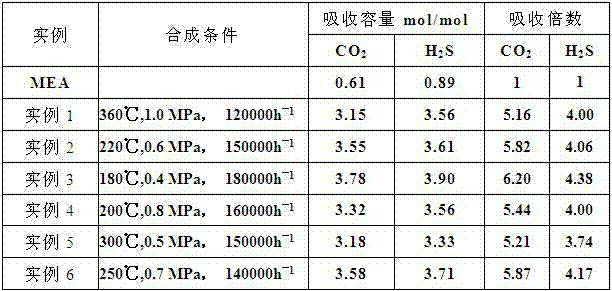

Examples

Embodiment 1

[0025] Crush 88g of porous silica gel into 30-50nm powder, dry at 100°C for 2 hours, then calcinate at 400°C for 2h in a horse boiling furnace, take it out and cool it to room temperature for later use; put 39g of Ni(NO 3 ) 2 ·6H 2 O, 3g Cu(NO 3 ) 2 ·3H 2 O and 1.5g La(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to form a mixed solution; 0.01g 2H 3 PO 4 ·24WO 3 48H 2 O is dissolved in deionized water to form a solution and is ready for use; add silica gel powder to the mixed solution, add 0.15mol ammonium bicarbonate or ammonium bicarbonate while stirring to form a precipitate, mature at 80 °C for 2 hours, filter, remove the filtrate, and keep the precipitate The precipitate is dried at 100°C for 4 hours, then calcined in a horse-boiling furnace at 350°C for 4 hours, cooled and then immersed in phosphotungstic acid solution, and evaporated to dryness in a water bath at 80°C; the evaporated matter is dried at 100°C for 4 hours , and then calcined at 350°C for 4...

Embodiment 2

[0027] Crush 71.5g of porous silica gel into 30-50nm powder, dry at 150°C for 3 hours, then calcinate at 350°C for 3h in a horse boiling furnace, take it out and cool it to room temperature for later use; put 78g of Ni(NO 3 ) 2 ·6H 2 O, 9g Cu(NO 3 ) 2 ·3H 2 O and 6.6g La(NO 3 ) 3 ·6H 2O was dissolved in deionized water to form a mixed solution; 0.5g 2H 3 PO 4 ·24WO 3 48H 2 O is dissolved in deionized water to form a solution and is ready for use; add silica gel powder to the mixed solution, add 0.32mol ammonium bicarbonate or ammonium bicarbonate while stirring to form a precipitate, mature at 100 °C for 3 hours, filter, remove the filtrate, and keep the precipitate The precipitate is dried at 150°C for 5 hours, then calcined in a horse-boiler furnace at 400°C for 5 hours, cooled and then immersed in phosphotungstic acid solution, and evaporated to dryness in a water bath at 90°C; the evaporated matter is dried at 150°C for 5 hours , and then calcined at 400°C for 5...

Embodiment 3

[0029] Crush 49g of porous silica gel into 30-50nm powder, dry at 200°C for 4 hours, then calcinate at 500°C for 4h in a horse boiling furnace, take it out and cool it to room temperature for later use; put 136g of Ni(NO 3 ) 2 ·6H 2 O, 15g Cu(NO 3 ) 2 ·3H 2 O and 13.5g La(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to form a mixed solution; 1g 2H 3 PO 4 ·24WO 3 48H 2 O is dissolved in deionized water to form a solution and is ready for use; add silica gel powder to the mixed solution, add 0.56mol ammonium bicarbonate or ammonium bicarbonate under stirring to form a precipitate, mature at 120 °C for 5 hours, filter, remove the filtrate, and keep the precipitate The precipitate was dried at 180°C for 6 hours, then calcined in a horse-boiler furnace at 500°C for 6 hours, cooled and then immersed in phosphotungstic acid solution, and evaporated to dryness in a water bath at 100°C; the evaporated matter was dried at 180°C for 6 hours , and then calcined at 500°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com