Organic waste resource treatment apparatus

A technology of organic waste and treatment equipment, applied in the field of organic waste resource treatment equipment, can solve the problems of limited consumption, low value, poor benefit, etc., and achieve the effect of automation, low cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

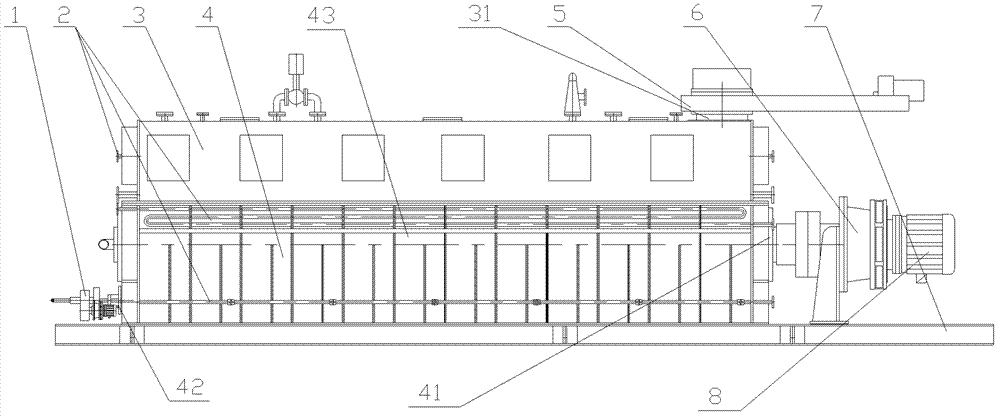

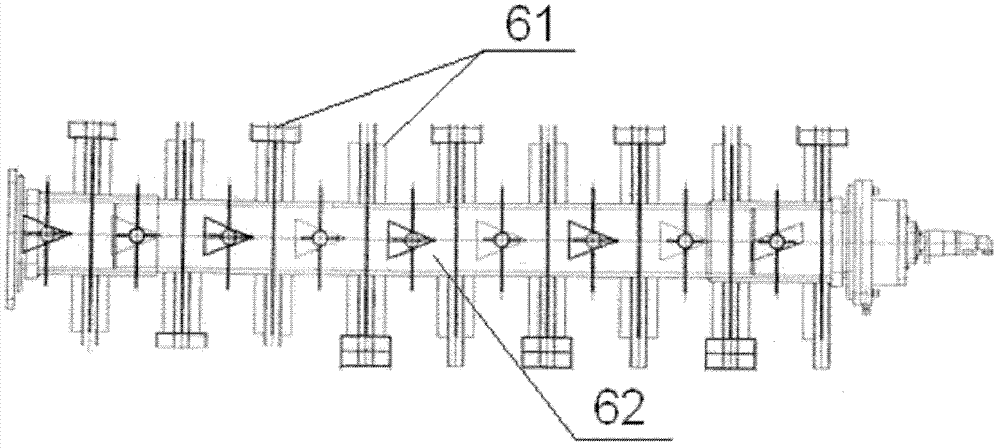

[0022] Such as figure 1 , 2 As shown, an organic waste resource treatment equipment includes a container 4, a bottom frame 7, a stirring and crushing roller assembly 6, a driving motor 8, an automatic feeding door device 5, a heat exchanger assembly 3, and an automatic discharging door device 1 and the pipeline assembly 2, the container 4 is fixed on the bottom frame 7, the lower part of the container 4 is provided with a discharge port 42, and the stirring and crushing roller assembly 6 consists of a roller shaft 62 and 9 sets of paddles 61 arranged on the roller shaft 62 at intervals Composition, the roller shaft 62 is installed on the bottom frame, and straddles the two ends of the container 4, the driving motor 8 is connected with the roller shaft 62, and drives the roller shaft 62 to rotate. The automatic discharge door device 1 is connected to the discharge port 42, the heat exchanger assembly 3 is arranged above the container 4, and a feed port 31 is arranged on it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com