Wet separation technology of municipal wet waste

A garbage sorting technology, which is applied in recycling technology, solid waste removal, furniture waste recycling, etc., can solve the problems of unsatisfactory urban wet garbage sorting and treatment requirements, unsatisfactory efficiency and effect, and decreased garbage sorting efficiency, etc. problems, to achieve the effect of reducing the amount of landfill leachate, realizing resource utilization, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

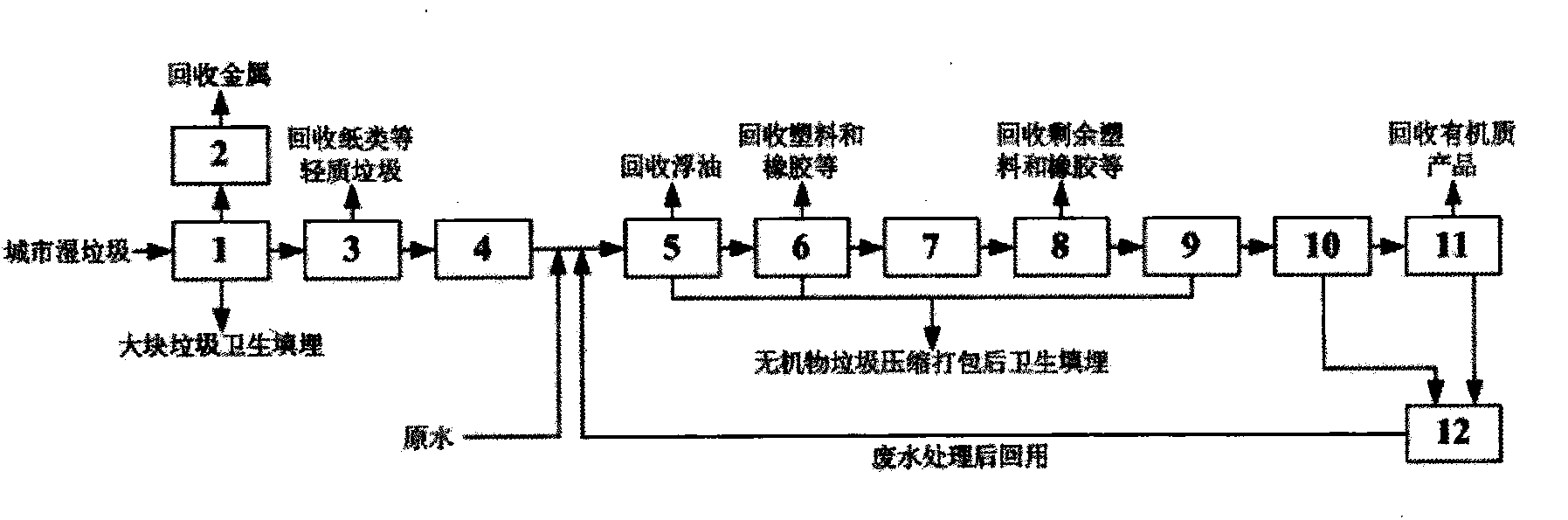

[0021] Such as figure 1 Shown is the process flow chart of a kind of wet sorting process of urban wet garbage provided by the present invention, taking the small-scale wet sorting demonstration line of daily processing 10 tons of urban wet garbage as an example:

[0022] Step 1: Urban wet garbage is continuously fed through the vibrating belt conveyor 1 to remove large pieces of heavy garbage such as bricks, concrete, etc., and the magnetic separator 2 placed above the vibrating belt conveyor 1 recycles the garbage Precious metals are selected by winnowing machine 3 to reclaim the paper in the rubbish, and then each component of rubbish is cut to 50mm long by shearing crusher 4.

[0023] Step 2: The crushed wet garbage is transported to the grease trap 5, and the flushing water with a weight 15 times that of the wet garbage is added to the grease trap 5, and the grease on the surface of the garbage liquid is scraped off by the grease trap baffle, and then the garbage liquid is...

Embodiment 2

[0030] The difference with embodiment 1 is that in the first step, each component of the rubbish is cut to 40 cm through the shear crusher 4; in the grease trap 5 of the second step, the flushing water whose weight is 20 times that of the wet rubbish is added.

[0031] The moisture content of the organic product was 9.3% and the doping rate was 3.1%. At the same time, the doping rate of the recyclable components was 4.0% and the doping rate of the inorganic components was 1.5%.

Embodiment 3

[0033] The difference with embodiment 1 is that in the first step, each component of the rubbish is cut to 45cm through the shear crusher 4; in the grease trap 5 of the second step, the flushing water whose weight is 18 times that of the wet rubbish is added.

[0034] The moisture content of the organic product was 9.2% and the doping rate was 3.5%. At the same time, the doping rate of the recyclable components was 4.3% and the doping rate of the inorganic components was 1.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com