Process for distributing grinding materials of grinding disc of ship body made of brass solder super-hard grinding material

A technology of superabrasives and grinding discs, applied in the direction of abrasives, grinding devices, manufacturing tools, etc., can solve the problems that it is difficult to effectively utilize the advantages of diamond abrasives, and can not be arranged in an orderly manner, so as to achieve large market potential and beautiful appearance , using reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

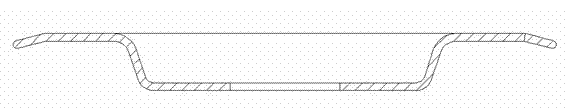

[0046] The orderly arrangement of abrasives for a new hull weld grinding disc is designed as follows:

[0047] Take a brazed diamond hull grinding disc with an outer diameter of 100mm as an example, such as Figure 5 As shown, its orderly arrangement scheme is:

[0048] ① The outer edge of the grinding disc is made of diamond abrasive, with a particle size of 30-35 mesh. The horizontal distance between two adjacent abrasive grains is 1.2mm, and the vertical distance is 1.5mm.

[0049] ② The upper inclined surface of the grinding disc is made of diamond abrasive, with a particle size of 35-40 meshes. The lateral distance between two abrasive grains along the radial direction is 1.0 mm, and the distance between two rows of abrasive grains distributed along the radial direction is 1.8 mm.

[0050] ③ The flat abrasives on the upper end of the grinding disc are arranged in circular clusters with a cluster diameter of 3 mm. Each cluster area is arranged with 10 to 15 diamonds of 50...

Embodiment 2

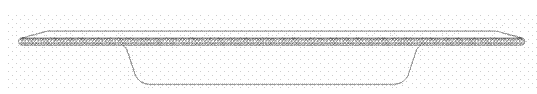

[0053] A kind of grinding disc and abrasive material arrangement scheme that can be applied to steel grinding and non-metallic grinding such as stone and polysilicon is designed as follows:

[0054] Take a brazed diamond grinding disc with an outer diameter of 125mm as an example, such as Figure 6 As shown, its orderly arrangement scheme is:

[0055] ① The outer edge of the grinding disc is made of diamond abrasive, with a particle size of 35-40 mesh. The horizontal distance between two adjacent abrasive grains is 1.5mm, and the vertical distance is 1.5mm.

[0056] ② The upper inclined surface of the grinding disc is made of diamond abrasive, with a particle size of 45-50 meshes, the transverse distance between two abrasive grains along the radial direction is 1.5 mm, and the distance between two rows of abrasive grains distributed along the radial direction is 2.0 mm.

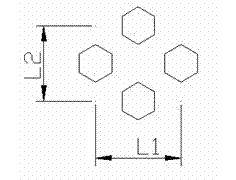

[0057] ③ The flat abrasives on the upper end of the grinding disc are arranged in clusters of regular tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com