Method for mineralizing seawater desalted water

A technology of carbon dioxide and reaction, applied in the field of water treatment, to facilitate production, reduce the Larson coefficient, and ensure the quality of water delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

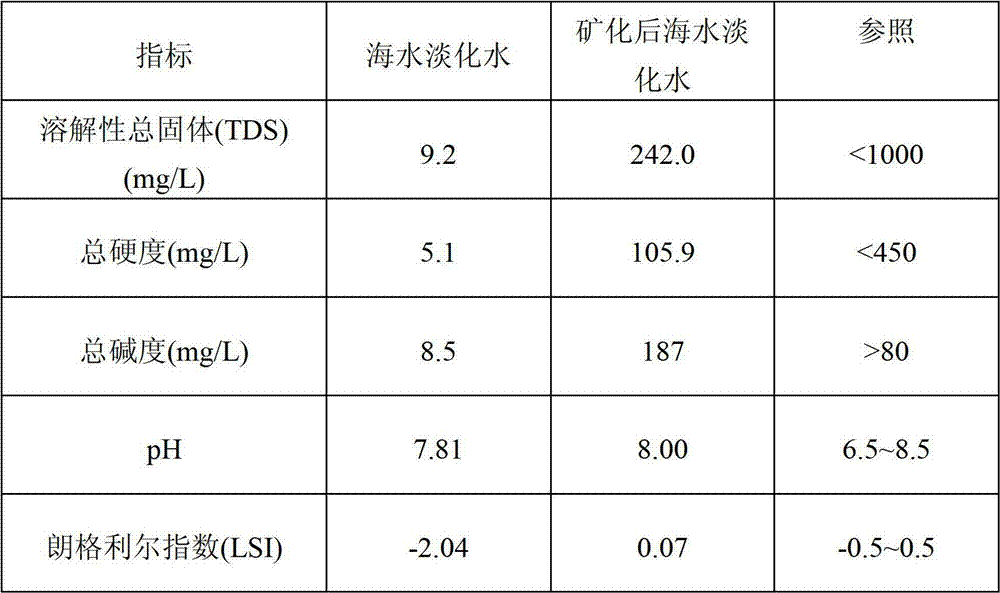

Embodiment 1

[0028] A method for mineralizing seawater desalinated water, the specific steps are as follows:

[0029] ⑴ Set the temperature of the constant temperature water bath to 5℃, and use a peristaltic pump to pump the water in the water bath into the reactor jacket to circulate;

[0030] (2) Take 1.5L of seawater desalination water into the reactor, when the temperature of the desalinated water reaches 5℃, weigh 0.75g of limestone into the reactor. Open CO 2 Pressure reducing valve, CO 2 The flow rate is set to 19mL / min, and CO is passed into the reactor 2 ;

[0031] ⑶ Turn on the stirrer, set the stirring frequency to 250r / min, and start timing. When the reaction reaches 20min, stop stirring and stop CO 2 , Take out the solution in the reactor and filter with a vacuum pump to obtain a clear liquid;

[0032] ⑷Inject a small amount of sodium hydroxide to adjust the pH to 7.5, the seawater desalination water is mineralized, and the mineralized seawater desalination water is obtained.

[0033]...

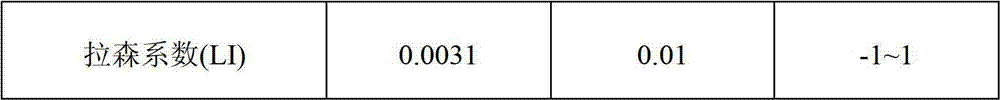

Embodiment 2

[0054] A method for mineralizing seawater desalinated water, the specific steps are as follows:

[0055] ⑴ Set the temperature of the constant temperature water bath to 5℃, and use a peristaltic pump to pump the water in the water bath into the reactor jacket to circulate;

[0056] (2) Take 1.5L of seawater desalination water into the reactor, when the temperature of the desalinated water reaches 22°C, weigh 1g of limestone and add it to the reactor. Open CO 2 Pressure reducing valve, CO 2 The flow rate is set to 19mL / min, and CO is passed into the reactor 2 ;

[0057] ⑶ Turn on the stirrer, set the stirring frequency to 300r / min, and start timing. When the reaction reaches 15min, stop stirring and stop CO 2 , Take out the solution in the reactor and filter with a vacuum pump to obtain a clear liquid;

[0058] ⑷Inject a small amount of calcium hydroxide to adjust the pH to 8, and the mineralization of the desalinated water is completed, and the mineralized desalinated water is obtain...

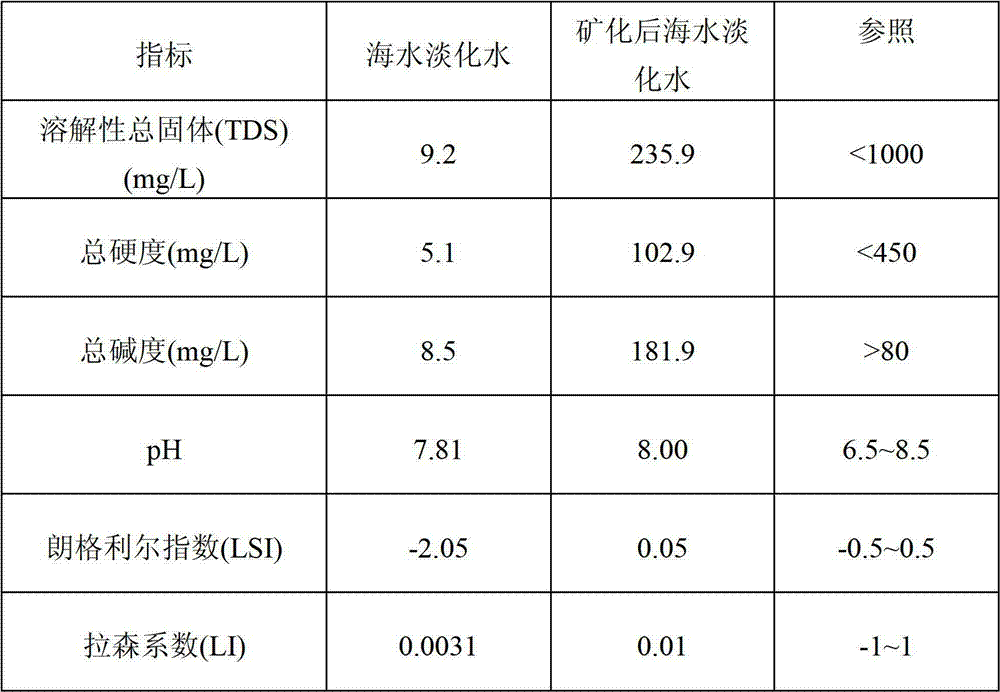

Embodiment 3

[0079] A method for mineralizing seawater desalinated water, the specific steps are as follows:

[0080] ⑴ Set the temperature of the constant temperature water bath to 5℃, and use a peristaltic pump to pump the water in the water bath into the reactor jacket to circulate;

[0081] (2) Take 1.5L of seawater desalinated water into the reactor, when the desalinated water temperature reaches 5℃, weigh 1.25g of limestone into the reactor. Open CO 2 Pressure reducing valve, CO 2 The flow rate is set to 19mL / min, and CO is passed into the reactor 2 ;

[0082] ⑶ Turn on the stirrer, set the stirring frequency to 150r / min, and start timing. When the reaction reaches 10min, stop stirring and stop CO 2 , Take out the solution in the reactor and filter with a vacuum pump to obtain a clear liquid;

[0083] ⑷Inject a small amount of calcium hydroxide to adjust the pH to 8, and the mineralization of the desalinated water is completed, and the mineralized desalinated water is obtained.

[0084] Inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com