Inorganic multi-element composite super-high-early grouting material and preparation method thereof

A multi-component composite and grouting material technology, which is applied in the field of grouting materials, can solve the problems of difficult control of the setting time of the system, large fluidity loss, and low hourly strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

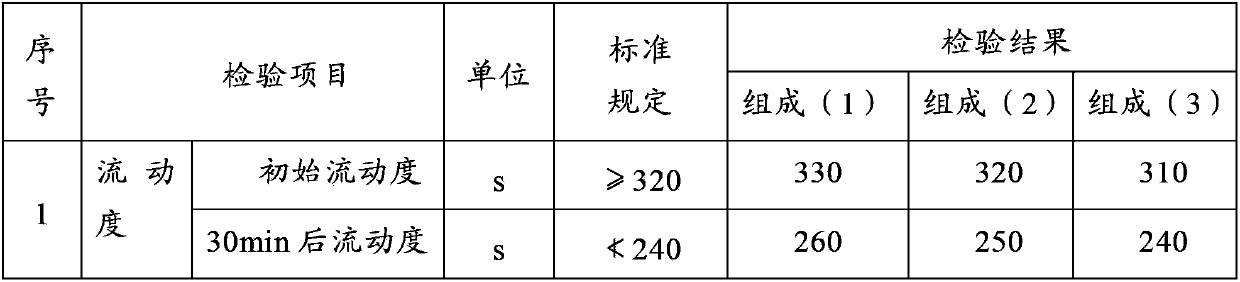

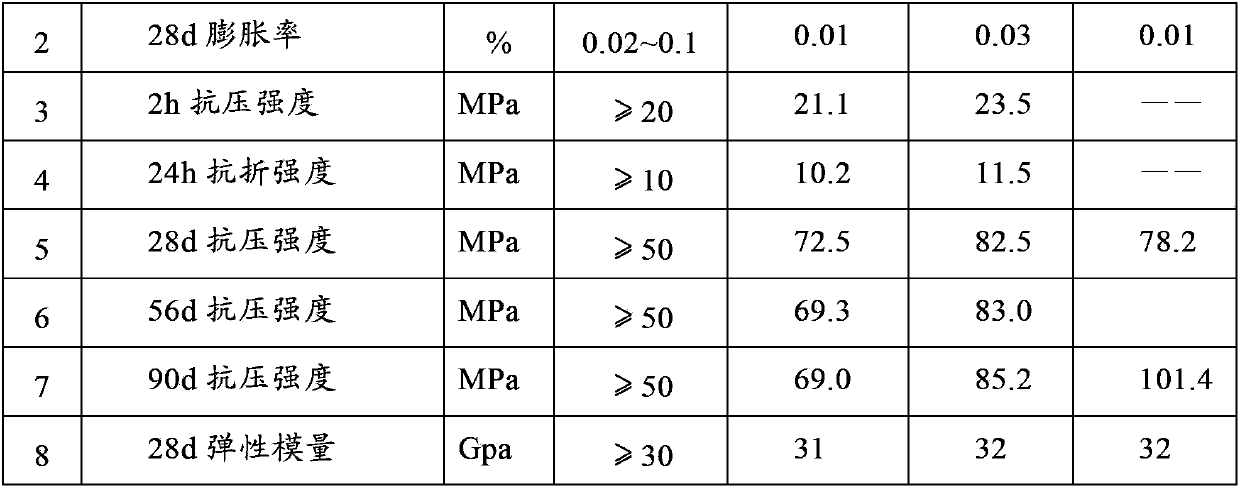

Examples

Embodiment 1

[0018] The cementitious material consists of 62 parts by weight of sulfoaluminate cement, 18 parts by weight of aluminate cement and 8 parts by weight of gypsum;

[0019] The auxiliary agent is composed of the following components accounting for the weight percentage of the gelling material: lithium carbonate 0.02%, sodium sulfate 1.0%, borax 0.3%, sodium tripolyphosphate 0.05%, sodium gluconate 0.01%, ferrous sulfate 0.4%, defoaming 0.15%, 0.2% of polypropylene fiber, and 1.4% of naphthalene series superplasticizer (such as purchased from Shanxi Huangteng Chemical Co., Ltd., Shanxi Kangker Fine Chemical Co., Ltd.);

[0020] Take 56 parts by weight of the above-mentioned cementing material, 42 parts by weight of quartz sand and the above-obtained auxiliary agent, and fully stir them with a coulter-type mixer (Shanghai Shuanglong Mixing Equipment Manufacturing Co., Ltd.) to obtain the inorganic multi-element composite of the present invention Super early strength grouting material. ...

Embodiment 2

[0022] The cementitious material consists of 64 parts by weight of sulfoaluminate cement, 20 parts by weight of aluminate cement and 9 parts by weight of gypsum;

[0023] The auxiliary agent is composed of the following components accounting for the weight percentage of the gelling material: lithium carbonate 0.03%, sodium sulfate 1.1%, borax 0.4%, sodium tripolyphosphate 0.06%, sodium gluconate 0.02%, ferrous sulfate 0.5%, defoaming 0.16%, 0.2% of polypropylene fiber, 1.5% of naphthalene-based superplasticizer;

[0024] Take 58 parts by weight of the above-mentioned cementing material, 40 parts by weight of quartz sand and the above-obtained auxiliary agent, and fully stir them with a coulter-type blender with flying knives to obtain the inorganic multi-element composite super early-strength grouting material of the present invention.

Embodiment 3

[0026] The cementitious material is composed of 66 parts by weight of sulfoaluminate cement, 22 parts by weight of aluminate cement and 11 parts by weight of gypsum;

[0027] The auxiliary agent is composed of the following components accounting for the weight percentage of the gelling material: lithium carbonate 0.04%, sodium sulfate 1.2%, borax 0.4%, sodium tripolyphosphate 0.07%, sodium gluconate 0.03%, ferrous sulfate 0.6%, defoaming 0.17%, 0.3% of polypropylene fiber, 1.6% of naphthalene series superplasticizer;

[0028] Take 63 parts by weight of the above-mentioned cementing material, 34 parts by weight of quartz sand and the above-mentioned additives, and fully stir them with a coulter-type blender with flying knives to obtain the inorganic multi-element composite super early-strength grouting material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com