A kind of matte PC coiled material and preparation method thereof

A PC sheet and coil technology, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of increasing the cost of use for customers, inconsistent frosting shape, and inability to make the best use of materials, etc., to achieve uniform frosting shape and effect, Easy to crop and use, reduce the effect of highlights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

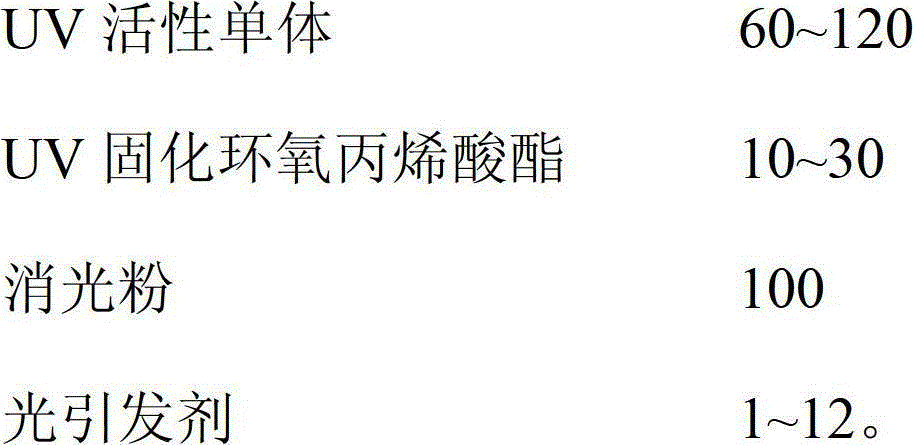

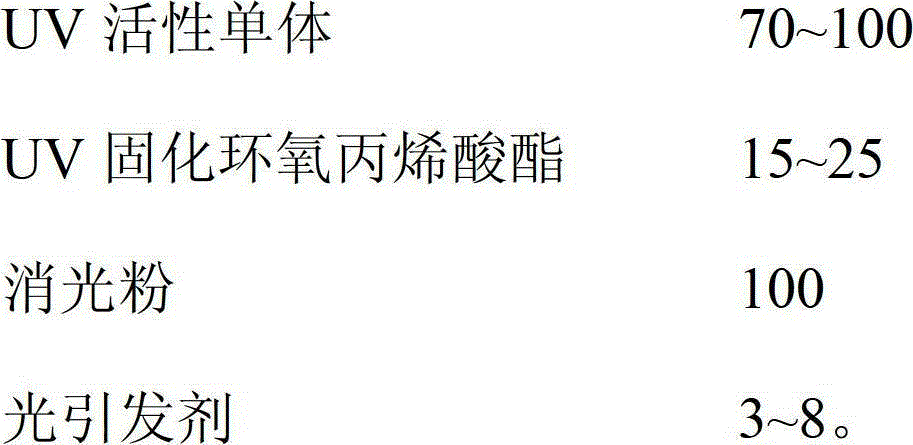

Method used

Image

Examples

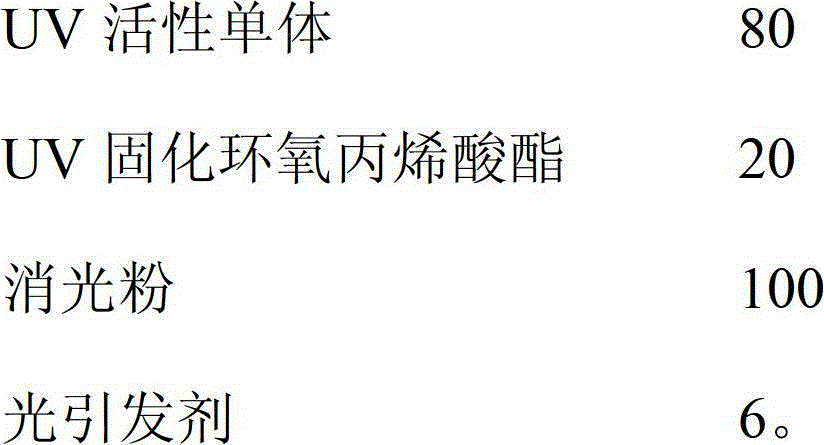

Embodiment 1

[0034] Select the PC sheet, then unwind, and use a high-precision coating machine to continuously coat the PC sheet with 10 parts of EM223, 30 parts of EM231, 40 parts of EM265, 20 parts of 621A-80, 100 parts of matting powder, 4 parts 184 and 2 parts of 1173 coating solution, then UV cured, and finally wound up to obtain a PC coil with a uniform frosting.

Embodiment 2

[0036] Select the PC sheet, then unwind it, and use a high-precision coating machine to continuously coat the PC sheet with 5 parts of EM223, 15 parts of EM231, 20 parts of EM265, 30 parts of 621A-80, 100 parts of matting powder, 1 part of 184 coating solution, then UV cured, and finally wound up to obtain a PC coil with a uniform frosting.

Embodiment 3

[0038] Select the PC sheet, then unwind it, and use a high-precision coating machine to continuously coat the PC sheet with 20 parts of EM223, 45 parts of EM231, 55 parts of EM265, 10 parts of 621A-80, 100 parts of matting powder, 8 parts 184 and 4 parts of 1173 coating solution, then UV cured, and finally wound up to obtain a PC coil with a uniform frosting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com