A method for simultaneous preparation of nanocellulose assisted by ultrasound and microwave

A nanocellulose and ultrasonic technology, applied in the direction of raw material separation, can solve problems such as rare reports and achieve the effect of rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

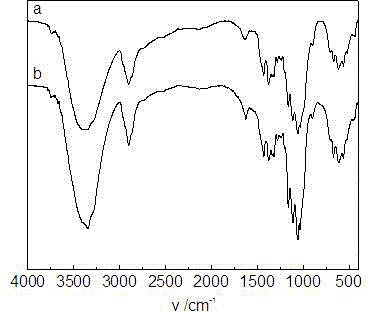

[0019] The preparation method of nanocellulose of the present invention comprises acid hydrolysis of plant cellulose, centrifugal recovery of liquid acid, centrifugal separation of nanocellulose; specifically comprises the following steps:

[0020] 1) Acid hydrolysis of plant cellulose: Take 0.5-3.0g of plant fiber material as raw material, mix it with liquid acid with a mass concentration of 10-60% and a volume of 40-60mL, place it in an ultrasonic-microwave co-extractor, Under -80℃ and ultrasonic-microwave assisted hydrolysis reaction for 0.5-2.0h and then ready for use.

[0021] 2) Centrifugal recovery of liquid acid: centrifuge the mixture in step 1) at 4000-7000rad / min for 5-10min, and the collected supernatant is the liquid acid solution, which can be recycled after the water is removed by rotary evaporation. Solid phase spare.

[0022] 3) Centrifugal separation of nanocellulose: Mix the solid phase product of step 2) with 50-200mL deionized water, adjust the pH value t...

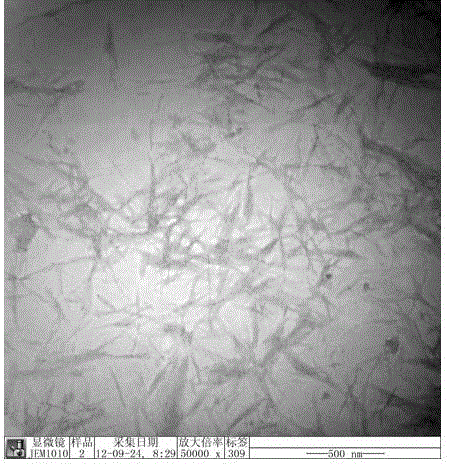

Embodiment 1

[0024] A method for simultaneously assisting the preparation of nanocellulose by ultrasonic waves and microwaves, comprising the following steps:

[0025] 1) Acid hydrolysis of plant cellulose: Take 0.5g of filter paper fragments and mix them with 50% mass concentration and 40mL of sulfuric acid, and then use ultrasonic-microwave at 65°C in an ultrasonic-microwave combined extraction apparatus (ultrasonic: 40KHz, 50W; microwave: 2450MHz, 10-800W automatically adjusted according to the set temperature) and auxiliary reaction for 1.5h before standby.

[0026] 2) Centrifugal recovery of liquid acid: centrifuge the mixture in step 1) at 6000rad / min for 7min, and the collected supernatant is the sulfuric acid solution, which can be recycled after the water is removed by rotary evaporation, and the solid phase at the bottom is ready for use.

[0027] 3) Centrifugal separation of nanocellulose: Mix the solid phase product of step 2) with 100 mL of deionized water, adjust the pH value...

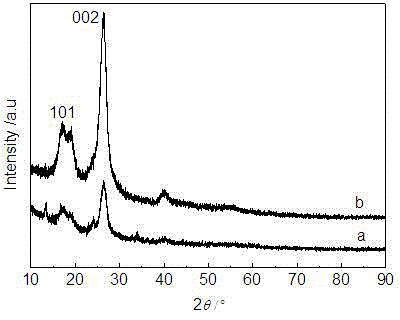

Embodiment 2

[0029] A method for simultaneously assisting the preparation of nanocellulose by ultrasonic waves and microwaves, comprising the following steps:

[0030] 1) Acid hydrolysis of plant cellulose: take 1.5g of wood pulp fiber and 55% mass concentration of phosphoric acid, 50mL of phosphoric acid fully mixed, in the ultrasonic-microwave combined extraction apparatus at 60 ℃ ultrasonic-microwave (ultrasonic: 40KHz, 50W; microwave : 2450MHz, 10-800W is automatically adjusted according to the set temperature) and the auxiliary reaction is 2.0h later.

[0031] 2) Centrifugal recovery of liquid acid: centrifuge the mixture in step 1) at 5000rad / min for 8min, and the collected supernatant is the phosphoric acid solution, which can be recycled after the water is removed by rotary evaporation, and the bottom solid phase is ready for use.

[0032] 3) Centrifugal separation of nanocellulose: Mix the solid phase product of step 2) with 150 mL of deionized water, adjust the pH value to neutra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com