Water-soluble film paper and preparation method thereof

A water-soluble film and film paper technology, applied in special paper, paper, papermaking, etc., can solve the problems of easy peeling and cleaning, and achieve the effect of improving surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

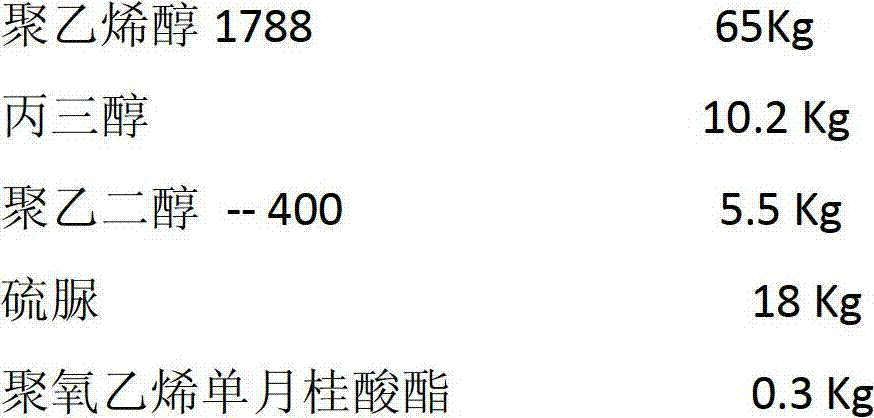

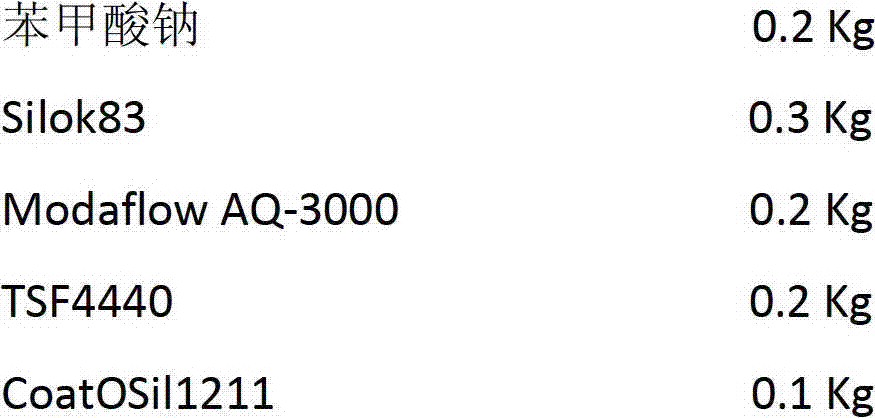

[0035] The formula of film paper raw material consists of:

[0036]

[0037]

[0038] A preparation method of water-soluble film paper, comprising the following steps:

[0039] (1) Dissolution: Add the film paper raw material into 400Kg water, heat to 90°C until the material is completely dissolved;

[0040] (2) Film formation: keep the temperature of the solution in step (1) at 90°C, let it stand for defoaming and defoaming for 12 hours (it only takes 1 hour if ultrasonic defoaming and defoaming is used), and then cool to 50°C, It is cast onto a clean steel strip through the casting touch head, and then passed through 120-180°C (the temperature range here refers to the range of heating temperature control of the four drying areas in the drying tunnel: 120°C, 150°C, 180°C and 160°C ) drying tunnel for drying and film formation;

[0041] (3) Paper forming: After the film is dried and rolled, it is aged at room temperature for 24 hours, and then the film is unrolled and ...

Embodiment 2

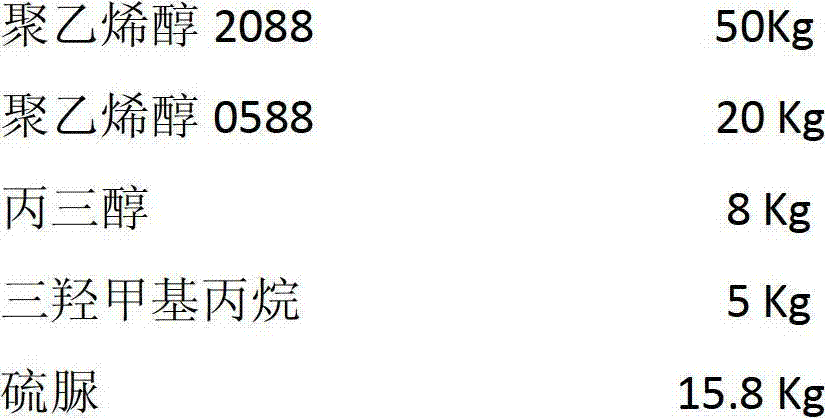

[0046] The formula of film paper raw material consists of:

[0047]

[0048]

[0049] A preparation method of water-soluble film paper, comprising the following steps:

[0050] (1) Dissolution: Add the film paper raw material into 500Kg water, heat to 90°C until the material is completely dissolved;

[0051] (2) Film formation: keep the temperature of the solution in step (1) at 90°C, let it stand for defoaming and defoaming for 12 hours, then cool to 60°C, cast it on a clean steel belt through a casting die, and then Dry and form a film through a drying tunnel at 120-180°C;

[0052] (3) Paper forming: After the film is dried and rolled, it is aged at room temperature for 24 hours, and then the film is unrolled and re-rolled to form an opaque white film paper.

[0053] After testing, the prepared water-soluble paper has a tensile strength of 26.3Mpa, an elongation at break of 183%, and a strong right-angle tear strength of 77KN / m; it can be written smoothly with water-...

Embodiment 3

[0056] The formula of film paper raw material consists of:

[0057]

[0058] A preparation method of water-soluble film paper, comprising the following steps:

[0059] (1) Dissolution: Add the film paper raw material into 450Kg water, heat to 95°C until the material is completely dissolved;

[0060] (2) Film formation: keep the temperature of the solution in step (1) at 92°C, let it stand for defoaming and defoaming for 12 hours, then cool to 50°C, cast it on a clean steel belt through a casting die, and then Dry and form a film through a drying tunnel at 120-180°C;

[0061] (3) Paper forming: After the film is dried and rolled, it is aged at room temperature for 24 hours, and then the film is unrolled and re-rolled to form an opaque white film paper.

[0062] After testing, the prepared water-soluble paper has a tensile strength of 24.5Mpa, an elongation at break of 179%, and a strong right-angle tear strength of 72KN / m; it can be written smoothly with water-based pens a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com