Construction method for road foundation

A construction method and foundation technology, applied in the directions of roads, roads, buildings, etc., can solve the problems that the bearing capacity of the roadbed cannot be met, the deformation modulus is reduced, and the construction cost is high, so as to reduce large-scale mining damage, reduce emissions, The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

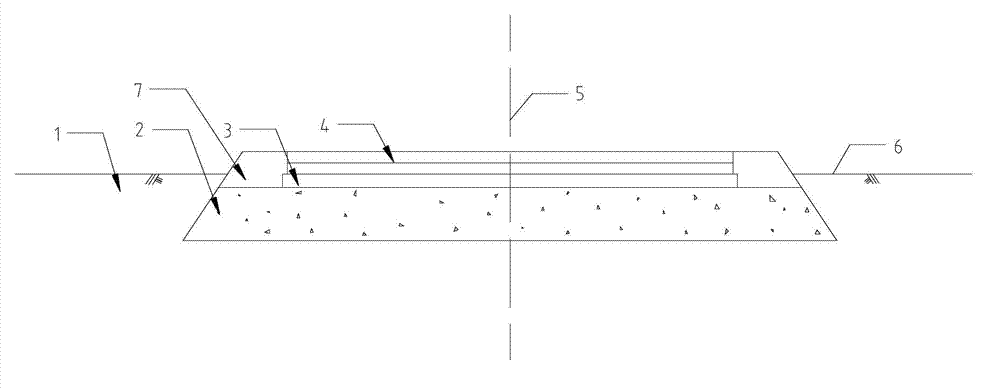

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0020] According to the above-mentioned geological conditions and engineering requirements, the specific process of backfilling construction with brick and slag subgrade is as follows: use a total station to measure the stakeout and a level to set out the line on the construction road section, set the subgrade centerline 5, and set up a pile every 15-20m on the straight line , set up a pile every 10-15m in the curve section, and set up indicator piles on the edges of the shoulders on both sides. The design elevation of the layer is marked with obvious marks on the indicator piles, and several representative points are selected on the construction road section. Drive the steel plate into the selected measuring point, and the top surface of the steel plate is flush with the testing surface.

[0021] Set up dewatering wells around the construction section with a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com