Non-inclined dry-operation open caisson capable of preventing water burst and land subsidence and construction method thereof

A technology of ground subsidence and dry operation, which is applied in the field of building foundations, can solve problems such as difficult to control verticality, long construction period, and high cost, so as to save foundation pit support and support engineering construction time, good construction quality, Effect without mud pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

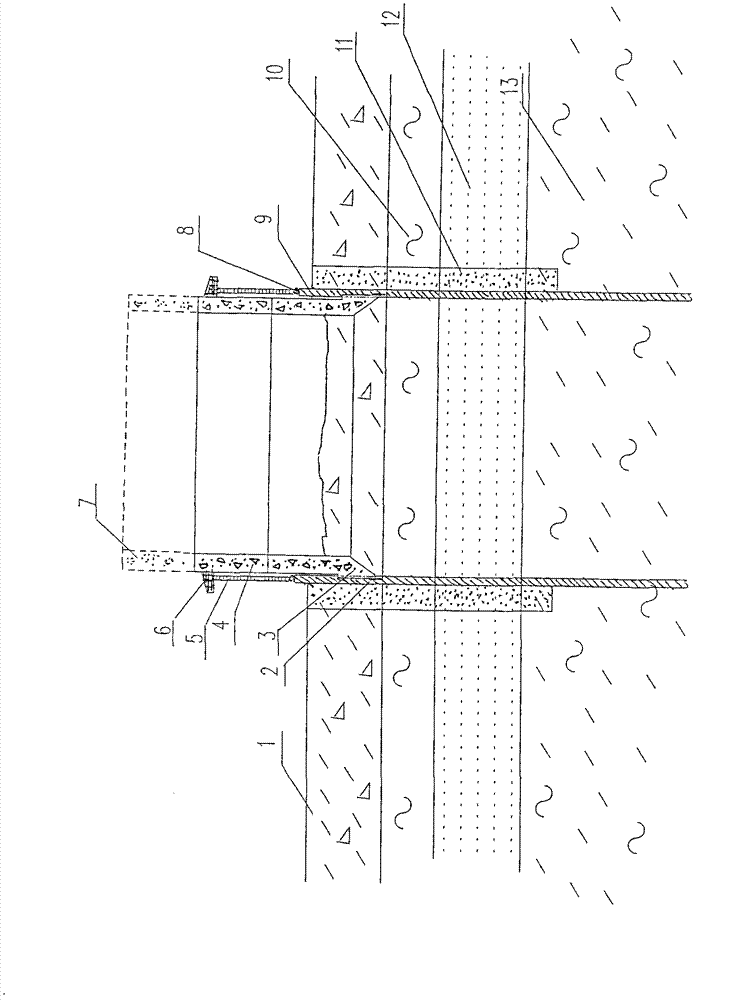

[0020] Such as figure 1 In the shown embodiment, the implementation of a non-inclined dry-operated caisson for preventing water inrush and ground subsidence is as follows: first construct the water-stop curtain (11) and uplift piles (9) around the caisson, and then make the bottom layer of the caisson Rebar binding, welding corbels (6) and mud-cut steel plates (2), formwork, pouring concrete (3, 4) and curing; demoulding after the caisson concrete (3, 4) reaches the strength, and the uplift pile (9) The two lifting devices (8) on the top of the pile are installed to remove the steel support (5) to the corbel (6) section by section, and the soil is excavated from the caisson (4) and transported outside. Take out, the lifting device (8) adopts stepping motor or manual operation, unified control caisson is vertical, does not tilt, sinks at a slow speed. Upper layer caisson well wall (7) continues upward construction by prior art, continues to excavate earth and settle down caiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com