Method for reducing self-consumption power of dual-mass combined cycle turbine

A combined cycle and turbine technology, applied in the field of steam turbines and gas turbines, can solve problems such as heat damage and increase the burden on compressors, achieve high thermal efficiency, reduce fuel consumption, and eliminate heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

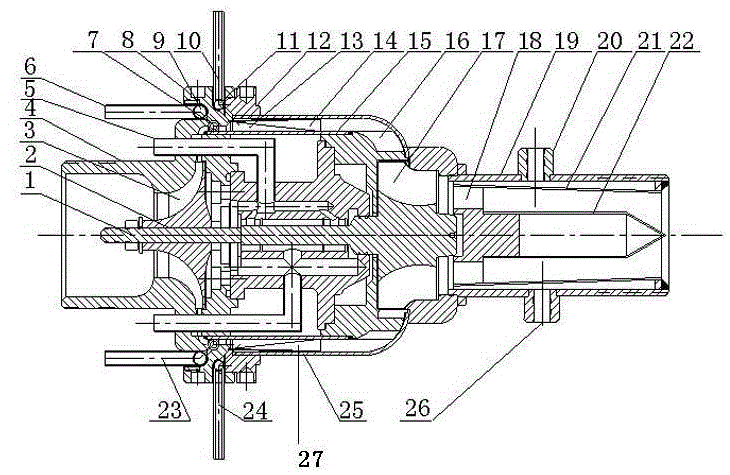

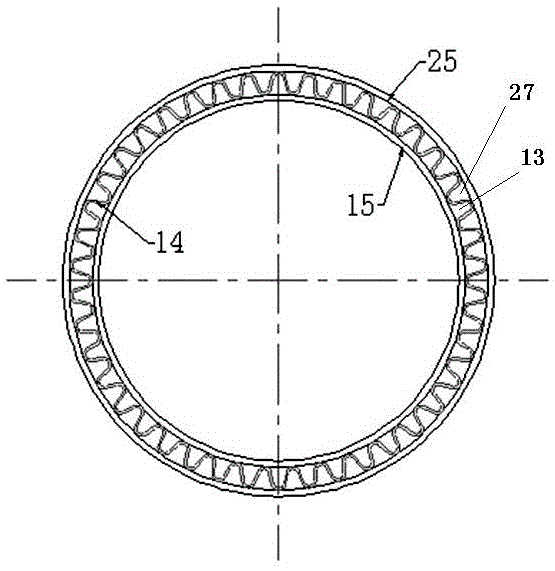

[0039] The energy-saving concept of dual-mass turbines is to increase the total amount of working fluid converted from thermal work as much as possible. If you want to improve the thermal power conversion capacity of the heat engine, if it is meaningless to change the calorific value of the fuel, you must change the "working medium".

[0040] The dual-mass turbine supplements the high-density liquid working medium to replace the low-density gaseous working medium, uses "residual heat" to make the phase change of the liquid working medium, reduces the compression work of the compressor, and completely replaces the large specific volume with water of small specific volume The air cooled by the combustion chamber and the turbine impeller does not need to compress the cooling medium, but only provides a little delivery power.

[0041] The dual-mass turbine only needs the compressor to provide sufficient oxygen supply air for the fuel according to the "gas-fuel ratio".

[0042] Can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com