Electropolymerization molecular imprinting technology-based double-parameter composite micro-sensor and preparation thereof

A molecular imprinting technology and micro-sensor technology, applied in the field of dual-parameter composite micro-sensor and preparation, can solve the problems of large equipment, high cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

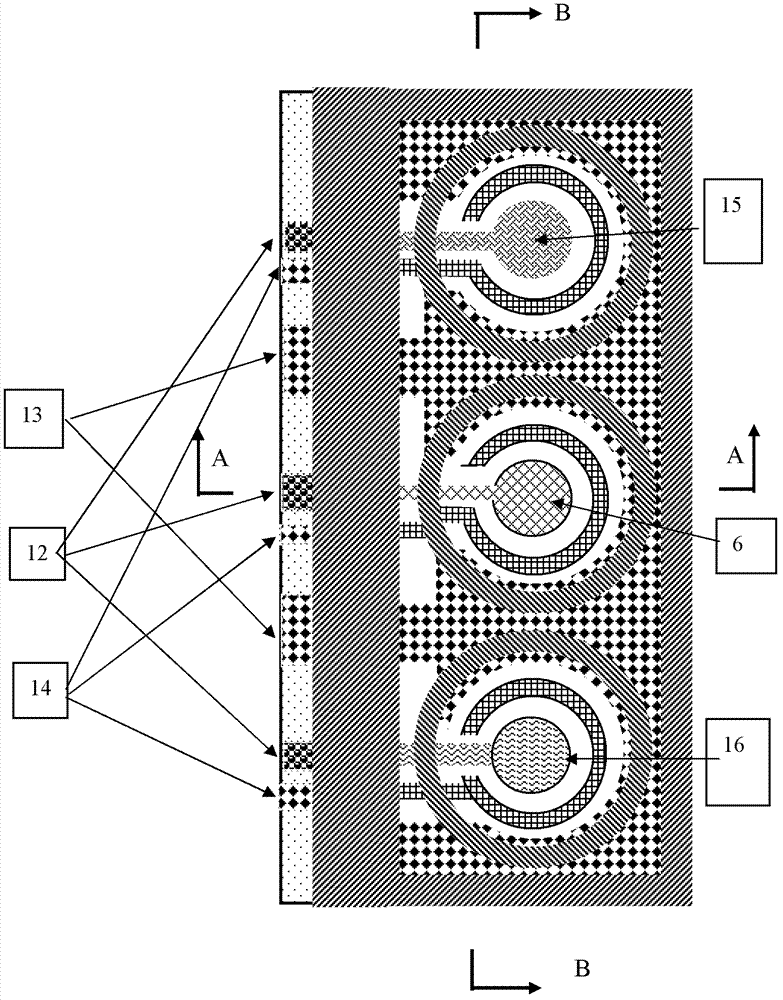

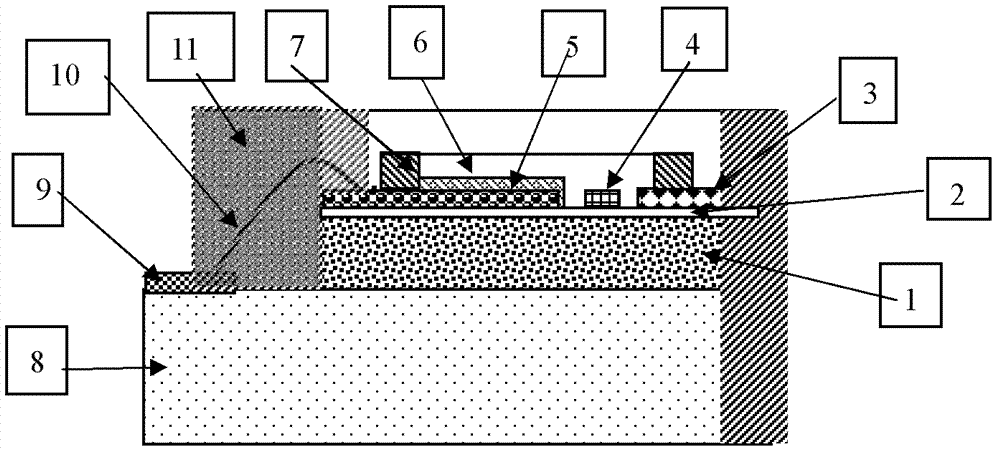

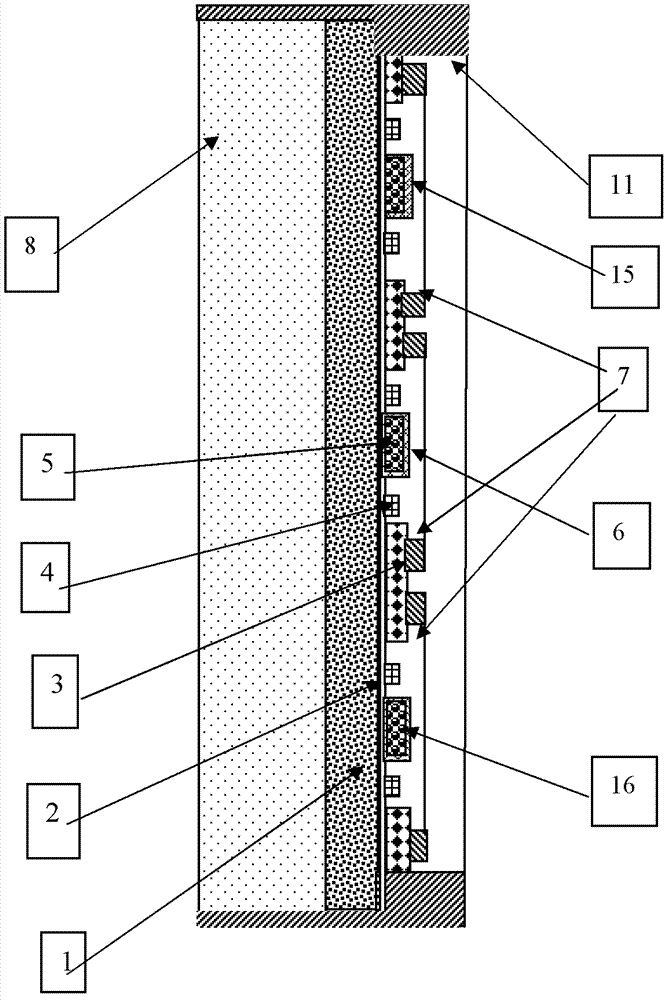

[0064] A creatinine / urea composite microsensor based on electropolymerization molecular imprinting of the present invention. Such as figure 1 , figure 2 , image 3 As shown, the implementation steps are as follows:

[0065]1. First choose silicon wafer or glass as the substrate (1);

[0066] 2. Growing a silicon dioxide insulating layer (2) on the surface of the silicon wafer (as glass is not required);

[0067] 3. Based on the Lift-off technology, the counter electrode (3) and the reference electrode (4) are formed by photolithography and sputtering Pt thin film 400nm technology;

[0068] 4. Based on the Lift-off technology, the working electrode (5) is formed by photolithography and sputtering Au thin film 400nm;

[0069] 5. Based on MEMS technology, SU8 glue is used to cast a three-dimensional ring (7) with a height of 30 μm on the silicon dioxide insulating layer of the chip, which surrounds the working electrode and the counter electrode to form a micro-reaction poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com