Terahertz wave polarization beam splitter connected in series with three semi-arc structures

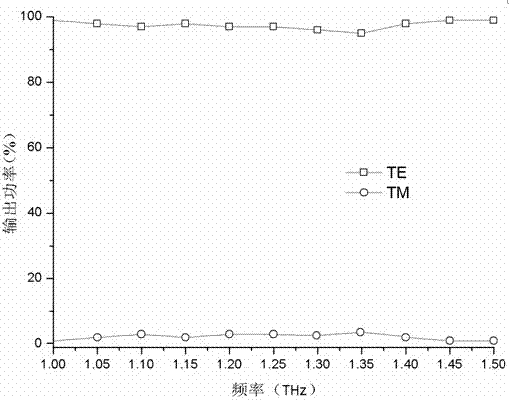

A polarizing beam splitter, terahertz technology, applied in the direction of instruments, coupling of optical waveguides, light guides, etc., can solve the problems of difficult manufacturing process, low transmittance, complex structure, etc., and achieve simple structure, high beam splitting rate, and size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

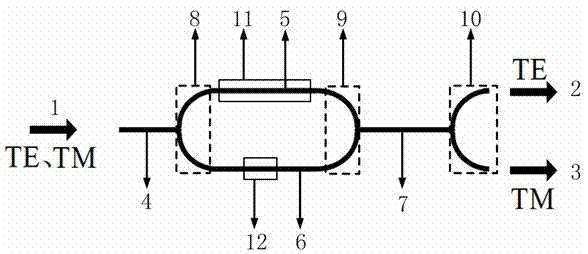

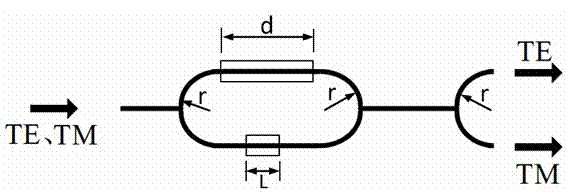

[0017] Terahertz wave polarizing beam splitters connected in series with three semi-circular structures:

[0018] The length of the first straight waveguide is 350 μm, the width is 300 μm, and the height is 250 μm; the length of the second straight waveguide is 500 μm, the width is 300 μm, and the height is 250 μm; the length of the third straight waveguide is 500 μm, the width is 300 μm, and the height is 250 μm ; The length of the fourth straight waveguide is 500 μm, the width is 300 μm, and the height is 250 μm. The length d of the first cladding layer was 450 μm, and the length L of the second cladding layer was 200 μm. Radii of the first semicircular waveguide structure, the second semicircular waveguide structure, and the third semicircular waveguide structure are all r, and r is 300 μm. Materials of the first cladding layer and the second cladding layer are birefringent materials. Materials of the first straight waveguide, the second straight waveguide, the third stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com