Electric discharge pump

A technology for discharge lamps and lamp housings, which is applied to the parts and components of gas discharge lamps, can solve the problems of low luminous efficiency of thermal discharge lamps, high thermal conductivity of arc tubes, loss of sodium discharge material, etc. The effect of less heat loss and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

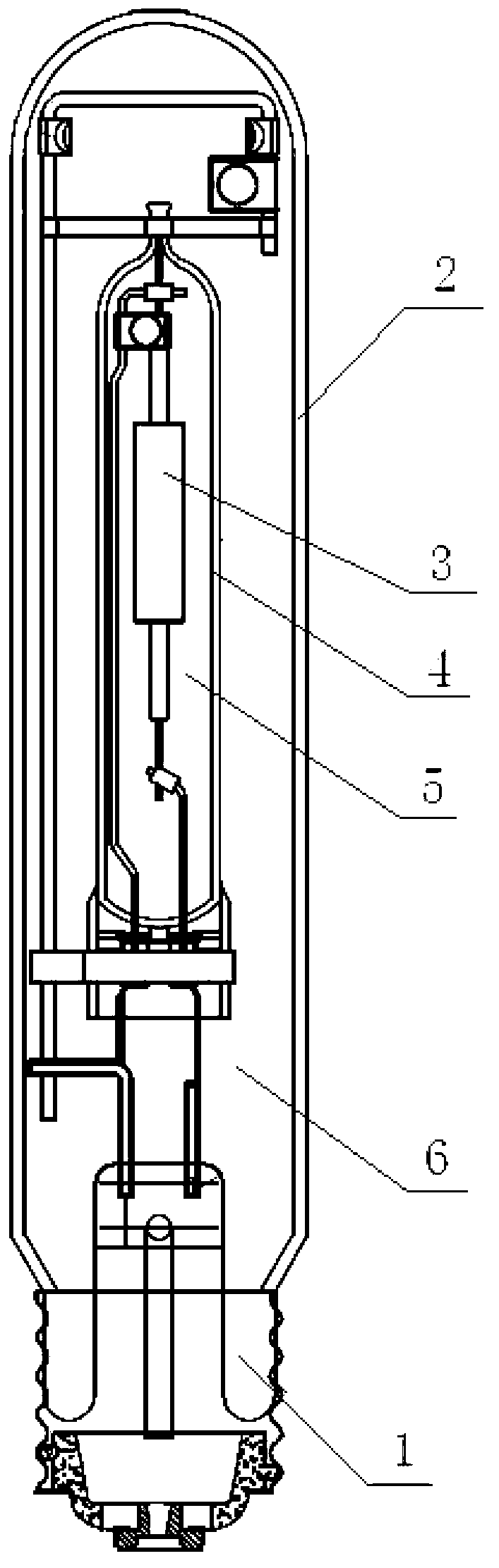

[0011] As shown in the figure, a discharge lamp includes a lamp cap 1, a lamp housing 2, and an arc tube 3 arranged in the lamp housing 2. A transition housing 4 is arranged between the arc tube 3 and the lamp housing 2, and the transition housing 4 is sealed and sleeved. On the periphery of the arc tube 3, the area 5 between the transition shell 4 and the arc tube 3 is filled with nitrogen-oxygen mixed gas with a pressure of 100 Pa to 1000 Pa and a volume content of oxygen of 0.5% to 5%. The transition shell 4 and the lamp shell 2 The area 6 between them is evacuated, and the transition shell 4 is made of quartz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com