Method for improving cycle performance and rate capability of lithium titanate battery

A lithium titanate battery, cycle performance technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary battery repair/maintenance, etc. Corrosion, the effect of solving battery flatulence

Inactive Publication Date: 2013-01-30

SHUANGDENG GRP

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to give full play to the excellent performance of lithium titanate materials, it is necessary to solve the problem of poor battery cycle life and rate performance caused by battery inflation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

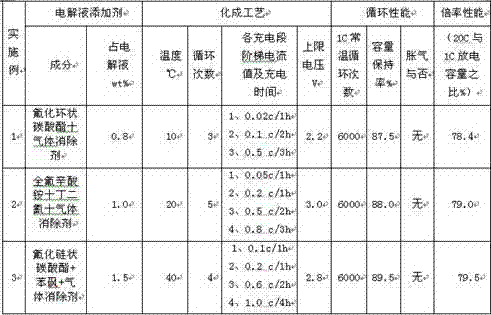

[0012] The present invention and battery test result are specified below by way of embodiment:

[0013]

[0014] The part not involved in the manufacturing process of lithium titanate battery is carried out according to the conventional process.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for improving the cycle performance and the rate capability of a lithium titanate battery. The main improvement is that additives including a stabilizer and a gas elimination agent are added into an electrolyte of the battery; the temperature is controlled to be 5 to 60 DEG C in a formation process of the battery; 3-6 sections of ladder currents from low to high are adopted for formation charge; the current interval is 0.02 to 1C; the charging time of each stage is 1 to 4 hours; and the upper limit voltage is 1.9 to 3.2V. By the method, the problem of battery swelling is solved effectively by adopting a complete and reasonable formation process and by using the electrolyte additives; the corrosion of substrates of an anode and a cathode is restrained; and therefore, the cycle performance and the rate capability of the lithium titanate battery are improved, and the requirements of a power lithium battery are met.

Description

technical field [0001] The invention relates to a lithium ion battery with a lithium titanate material as the negative pole, in particular to a method for improving cycle performance and rate performance of the lithium titanate battery. Background technique [0002] Conservation of oil resources, reduction of greenhouse gas emissions and air quality purification are the three major challenges facing the automotive industry in the world today. Power battery technology has always been the key to restricting the development of electric vehicles, and the research on lithium-ion batteries has received more attention and investment. The application of lithium-ion batteries in electric vehicles is promoting their development in the direction of safety, environmental protection, low cost and high specific energy. Electric vehicles require lithium-ion batteries to have low self-discharge rate, good fast charging performance, good overcharge and overdischarge resistance, high power d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/058H01M10/42

CPCY02E60/12Y02E60/10Y02P70/50

Inventor 张益明

Owner SHUANGDENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com