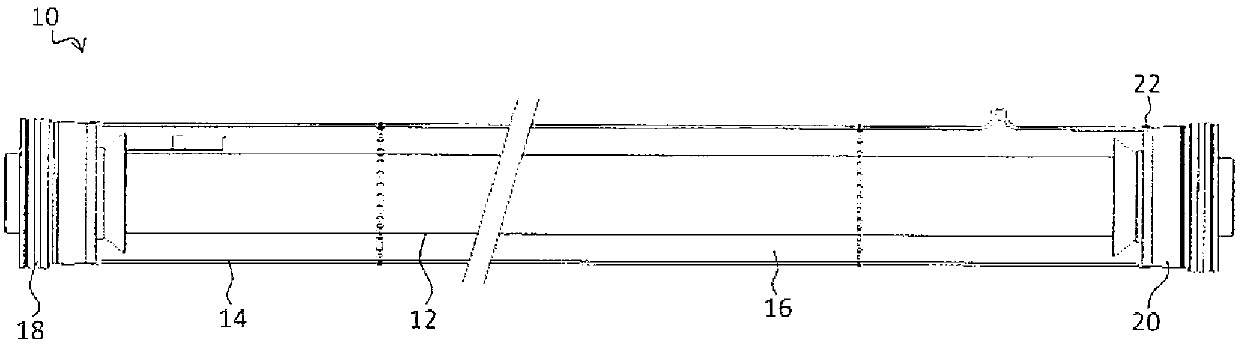

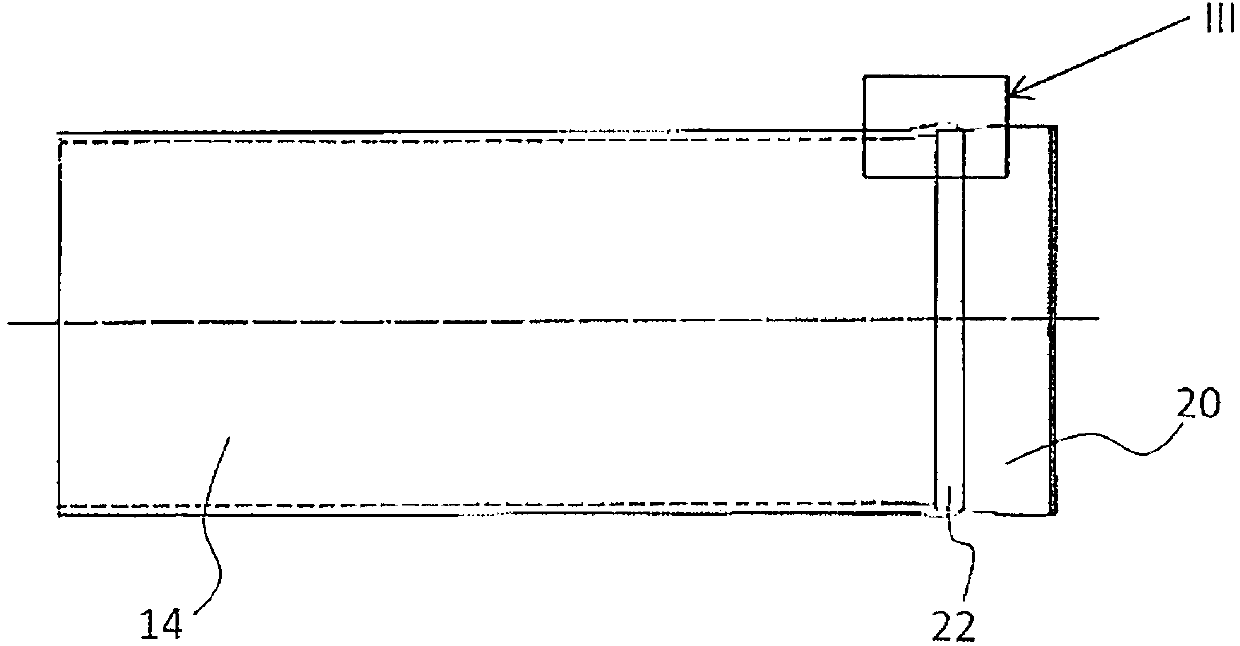

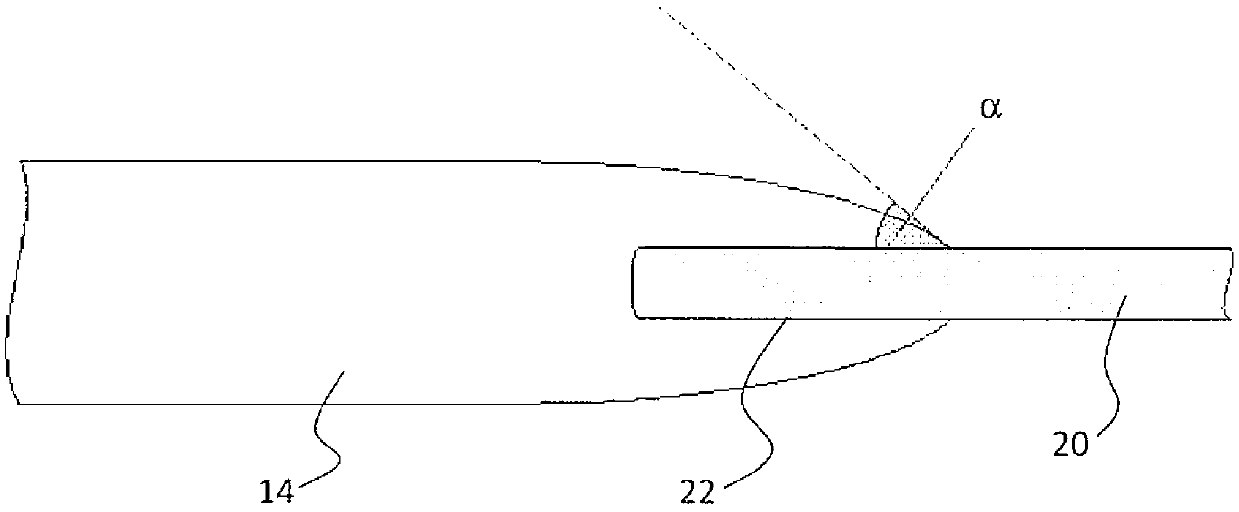

Improvements in tubular solar collectors

A technology of solar heat collectors and metal tubes, applied in the direction of solar heat collectors, fixed bases/supports of solar heat collectors, solar heat collectors using working fluids, etc., can solve complex and difficult-to-apply metal-glass joints , expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] According to the invention, a metal is provided for the metal-glass joint of a tubular solar collector 10, said metal having the following composition:

[0089]

[0090] Apart from unavoidable impurities, the remainder consists of iron. This composition satisfies the following conditions:

[0091] 45.5≤(Ni+Co)≤46.5

[0092] (Ti+Ta+Zr)≥4×C

[0093] Thus, after subjecting the metal to an oxidation process at 900 °C in air for 20 min without prior decarburization in wet hydrogen, an assembly of joints is provided between the proposed metal and borosilicate glass . The oxidized metal and glass were directly welded by placing them in contact at 800°C for 15 minutes and cooling the joint to ambient temperature under controlled conditions with a gradient of 1°C / min.

[0094] One joint from the assembly of metal-glass joints thus provided was subjected to metallographic analysis by cross-sectional observation to verify the possible presence of air bubbles in the glass an...

Embodiment 2

[0099] According to the invention, a metal is provided for a metal-glass joint of a tubular solar collector, said metal having the following composition (the composition actually used in the examples is presented):

[0100]

[0101] Apart from unavoidable impurities, the remainder consists of iron.

[0102] This composition satisfies the following conditions:

[0103] 45.5≤(Ni+Co)≤46.5

[0104] (Ti+Ta+Zr)≥4×C.

[0105] There is also provided a glass for use in a metal-glass joint of a tubular solar collector, said glass having the following composition:

[0106] B 2 o 3

Al 2 o 3

Na 2 o

K 2 o

CaO

Fe

12.3

6.8

6.8

2.5

0.5

200ppm

[0107] Except for unavoidable impurities, the remainder is SiO 2 .

[0108] Thus, after subjecting the metal to an oxidation process at 950 °C in air for 10 min without prior decarburization in wet hydrogen, an assembly of joints between the proposed metal and g...

Embodiment 3

[0114] According to the invention, a metal is provided for a metal-glass joint of a tubular solar collector, said metal having the following composition:

[0115]

[0116] Apart from unavoidable impurities, the remainder consists of iron.

[0117] This composition satisfies the following conditions:

[0118] 45.5≤(Ni+Co)≤46.5

[0119] (Ti+Ta+Zr)≥4×C

[0120] There is also provided a glass for use in a metal-glass joint of a tubular solar collector, said glass consisting essentially of:

[0121] B 2 o 3

al 2 o 3

Na 2 o

K 2 o

Fe

TiO 2

ZrO 2

Ta 2 o 5

CeO 2

Ba

9.8

6.2

5.9

3.8

200ppm

1.2

1.3

1.2

1.5

1.0

[0122] Except for unavoidable impurities, the remainder is SiO 2 .

[0123] Thus, after subjecting the metal to an oxidation process at 850 °C in air for 40 min without prior decarburization in wet hydrogen, an assembly of joints between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com