Fly ash plant fiber heat-insulating core building block

A technology of plant fiber and fly ash, which is applied in the field of thermal insulation blocks, can solve the problems of insufficient utilization and achieve the effects of high investment, low project cost and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

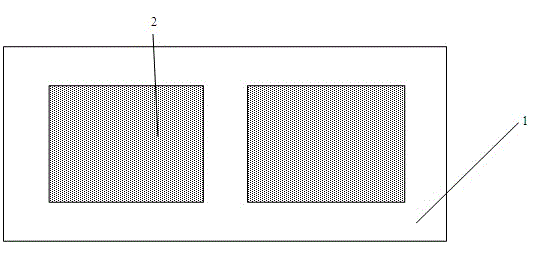

[0024] The fly ash plant fiber insulation core block proposed by the present invention is as follows: figure 1 shown. It is mainly composed of fly ash hollow block 1, plant fiber insulation core 2 and the like.

[0025] Prepare by following steps:

[0026] a. Make hollow blocks.

[0027] b. Plant fiber crushing, anti-corrosion and fire-proof treatment.

[0028] c. Stir the solid material of the plant fiber thermal insulation core, then add water, and stir evenly to form a plant fiber thermal insulation core slurry, which is poured into the hollow block, leveled and maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com