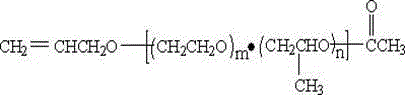

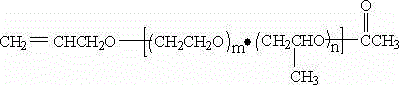

Preparation method of low-molecular-weight acetyl-terminated allyl alcohol polyether

A technology of terminal allyl alcohol polyether and allyl alcohol polyether, which is applied in the field of preparation of low molecular weight acetyl-terminated allyl alcohol polyether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The end-capping rate of the acetyl-terminated allyl alcohol random polyether finally prepared in this example was 96%, and the product indicators remained basically unchanged within one year.

[0020] The preparation method of a low-molecular-weight acetyl-terminated allyl alcohol polyether obtained by using this example has the following advantages: After dehydration to a certain content by high vacuum in a circulating spray dehydration reactor, the relative content of acetyl groups is greatly reduced. The degree of hydrolysis and deterioration of the low molecular weight acetyl-terminated allyl alcohol polyether during storage, at the same time, the oxygen in the barrel is reduced to a certain level by passing the inert gas when the finished polyether is packaged in the barrel, thereby reducing The degree of α-H of unsaturated double bonds and ether bonds in low molecular weight acetyl-terminated allyl alcohol polyethers with relatively high unsaturated double bond con...

Embodiment 2

[0023] The end-capping rate of the acetyl-terminated allyl alcohol random polyether finally prepared in this example was 97%, and the product indicators remained basically unchanged within one year.

[0024] The preparation method of a low-molecular-weight acetyl-terminated allyl alcohol polyether obtained by using this example has the following advantages: After dehydration to a certain content by high vacuum in a circulating spray dehydration reactor, the relative content of acetyl groups is greatly reduced. The degree of hydrolysis and deterioration of the low molecular weight acetyl-terminated allyl alcohol polyether during storage, at the same time, the oxygen in the barrel is reduced to a certain level by passing the inert gas when the finished polyether is packaged in the barrel, thereby reducing The degree of α-H of unsaturated double bonds and ether bonds in low molecular weight acetyl-terminated allyl alcohol polyethers with relatively high unsaturated double bond con...

Embodiment 3

[0027] The end-capping rate of the acetyl-terminated allyl alcohol random polyether finally prepared in this example was 98%, and the product indicators remained basically unchanged within one year.

[0028] The preparation method of a low-molecular-weight acetyl-terminated allyl alcohol polyether obtained by using this example has the following advantages: After dehydration to a certain content by high vacuum in a circulating spray dehydration reactor, the relative content of acetyl groups is greatly reduced. The degree of hydrolysis and deterioration of the low molecular weight acetyl-terminated allyl alcohol polyether during storage, at the same time, the oxygen in the barrel is reduced to a certain level by passing the inert gas when the finished polyether is packaged in the barrel, thereby reducing The degree of α-H of unsaturated double bonds and ether bonds in low molecular weight acetyl-terminated allyl alcohol polyethers with relatively high unsaturated double bond con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com