Modified polystyrene material with high cell adhesion capacity and preparation method of modified polystyrene material

A technology of polystyrene and cell adhesion, applied in biochemical equipment and methods, tissue cell/virus culture devices, biochemical instruments, etc., can solve the problems of expensive, unfavorable large-scale production, etc., and achieve improved efficiency and simple operation , No secondary pollution source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, preparation modified polystyrene culture plate

[0024] Put a commercially available common polystyrene cell culture plate in an air atmosphere, put it into a commercially available medical sealed bag, and seal it with the self-applied glue of the sterilization tape, and then use it 60 Coγ-rays were irradiated in air at room temperature, the radiation dose rate was 30Gy / min, and the absorbed dose was 50kGy; after the irradiation was completed, a modified polystyrene culture plate was obtained.

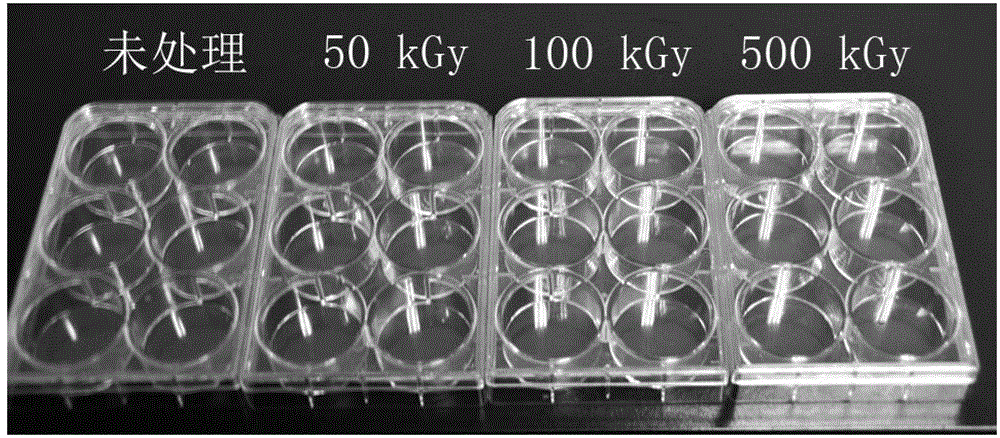

[0025] The photos of modified polystyrene prepared in this embodiment and unmodified polystyrene are as follows: figure 1 shown. Depend on figure 1 It can be seen that the appearance of modified polystyrene has no obvious change from that before modification.

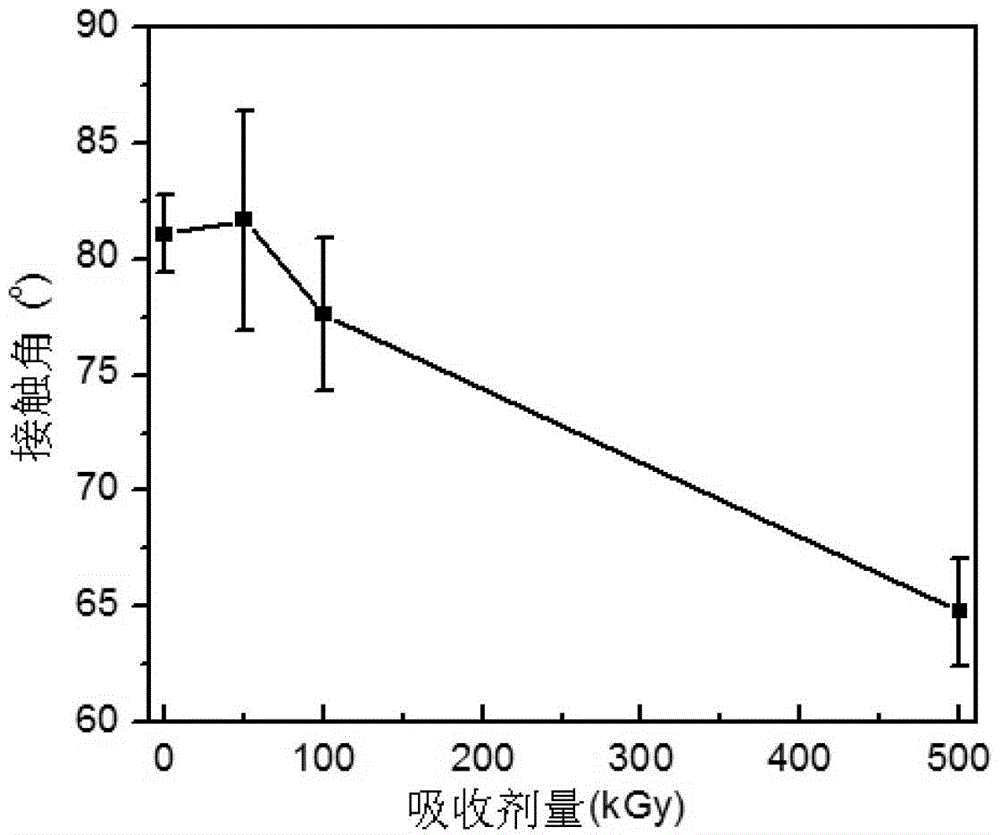

[0026] The water contact angles of modified polystyrene prepared in this embodiment and unmodified polystyrene are as follows: figure 2 shown. Depend on figure 2 It can be seen that the surface conta...

Embodiment 2

[0030] Embodiment 2, preparation modified polystyrene culture plate

[0031] The preparation process of this example is basically the same as that of Example 1, except that the radiation dose rate is changed to 50Gy / min, and the absorbed dose is changed to 100kGy.

[0032] Observe the modified polystyrene material prepared in this example according to the method for measuring the appearance of the material in Example 1. Such as figure 1 As shown, the overall color of the modified polystyrene prepared in this embodiment is more yellow. It shows that the color of modified polystyrene gradually turns yellow with the increase of irradiation dose.

[0033] Observe the modified polystyrene material prepared in this example according to the method for measuring the surface contact angle of water in the material in Example 1. Such as figure 2 As shown, the surface contact angle of the modified polystyrene prepared in this example to water is lower to some extent than that before ...

Embodiment 3

[0036] Embodiment 3, preparation modified polystyrene culture plate

[0037] The preparation process of this example is basically the same as that of Example 1, except that the radiation dose rate is changed to 100Gy / min, and the absorbed dose is changed to 500kGy.

[0038] Observe the modified polystyrene material prepared in this example according to the method for measuring the appearance of the material in Example 1. Such as figure 1 As shown, the overall color of the modified polystyrene prepared in this embodiment is more yellow. It shows that the color of modified polystyrene turns yellow and darkens with the increase of irradiation dose.

[0039] Observe the modified polystyrene material prepared in this example according to the method for measuring the surface contact angle of water in the material in Example 1. Such as figure 2 As shown, the surface contact angle of the modified polystyrene prepared in this example to water is lower to some extent than that befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com