Waterproof efficient intumescent fire retardant coating

A kind of technology of fireproof coating and expansion type, applied in the direction of fireproof coating, coating, etc., can solve the problems of resin stability damage, affect water resistance, accelerate resin aging and degradation, etc., achieve good rain erosion resistance, good heat insulation effect, The effect of long service life

Active Publication Date: 2013-02-06

PRESAFER QINGYUAN PHOSPHOR CHEM

View PDF4 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Small molecules in ammonium polyphosphate will not only affect its water resistance, but also accelerate the degradation of ammonium polyphosphate, resulting in more small molecular acids and ammonium salts, which will cause the coating to swell and foam when it meets water during use. Molecular substances will also have a destructive effect on the stability of the resin, and accelerate the aging and degradation of the resin internally, so it has a great impact on the fireproof performance, water resistance and weather resistance of the fireproof coating, and seriously affects the service life of the coating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

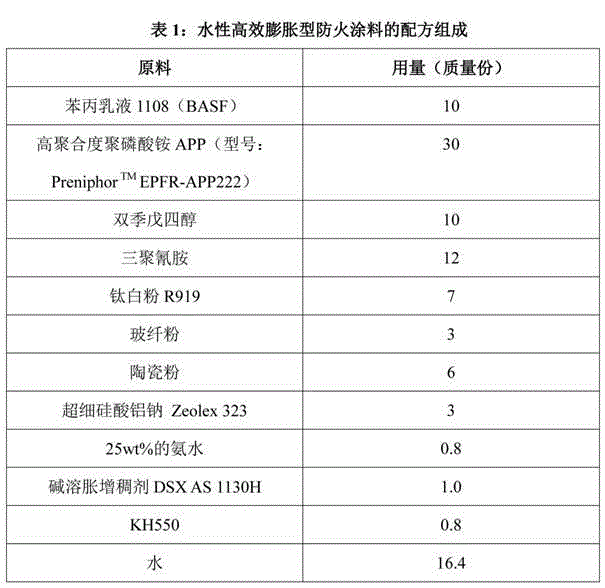

Embodiment 1

[0021] A kind of water-based high-efficiency expansion type fireproof coating, its raw material formula is as follows table 1:

[0022]

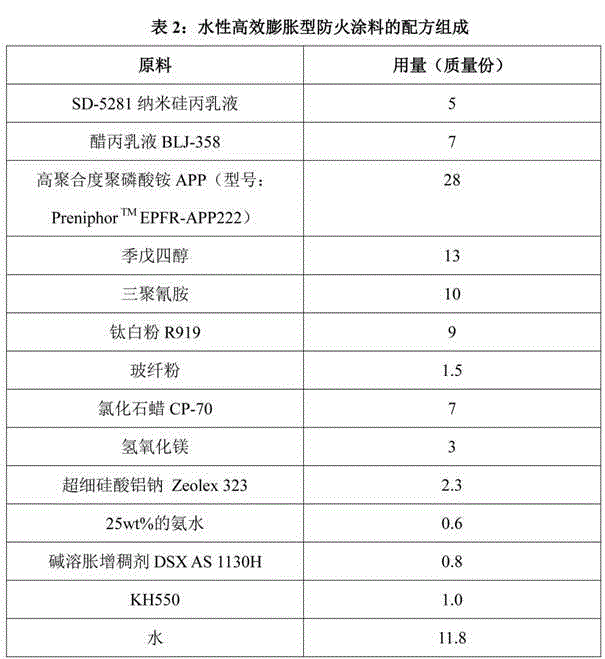

Embodiment 2

[0024] A water-based high-efficiency expansion type fireproof coating, its raw material formula is composed as follows Table 2:

[0025]

Embodiment 3

[0027] A water-based high-efficiency intumescent fireproof coating, its raw material formula composition is as follows Table 3:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a waterproof efficient intumescent fire retardant coating. The waterproof efficient intumescent fire retardant coating is prepared from, by mass, 40-75 parts of inrumescent flame retardant, 8-15 parts of film formers, 7-10 parts of pigment, 9-15 of fillers, 0-5 parts of adjuvant, and 10-30 parts of water. After being formed into film, the waterproof efficient intumescent fire retardant coating is better in water resistance, long in service life, solid in densification of formed carbon layer, good in heat insulation effect, and long in fireproofing time.

Description

technical field [0001] The invention relates to a water-based high-efficiency expansion type fireproof coating. Background technique [0002] Intumescent fire retardant coating is a kind of functional coating, which can form a layer of dense carbon layer on the coated surface that is dozens or even hundreds of times the thickness of the paint film in the event of a fire, effectively protecting the substrate from heat and oxygen. It has the advantages of low density, easy construction, low cost, and can be used in various complex shapes and surfaces. It is widely used in fire protection in many places such as steel structures, cables, ceilings, walls, tunnels, and aircraft. [0003] Due to the development of environmental protection and new technology and new material technology, the use of new water-soluble fireproof coatings has become a trend. Not only its physical and mechanical properties are close to organic solvent-based fireproof coatings, but also its toxicity and sa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D125/14C09D131/04C09D133/04C09D127/06C09D5/18C09D7/12

Inventor 翟勇强谢思正周侃

Owner PRESAFER QINGYUAN PHOSPHOR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com