Creep aging forming method for Al-Cu-Mg series alloy sheet material

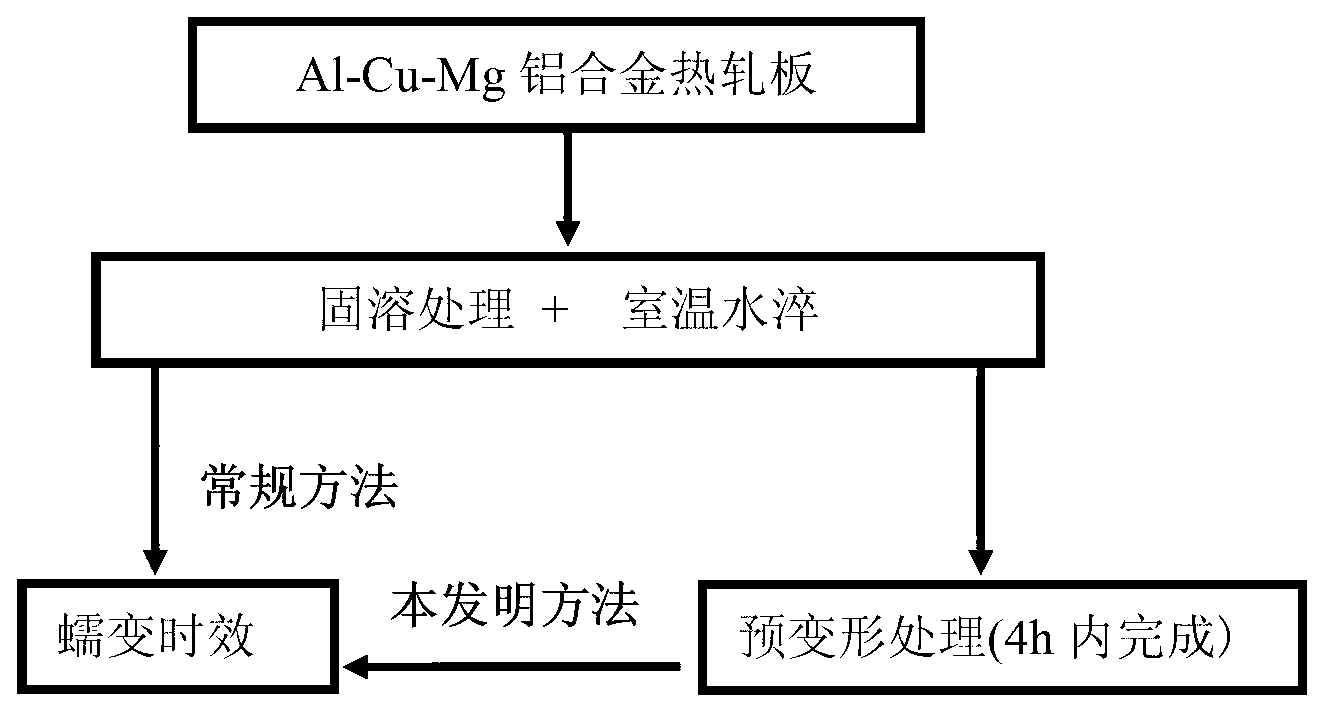

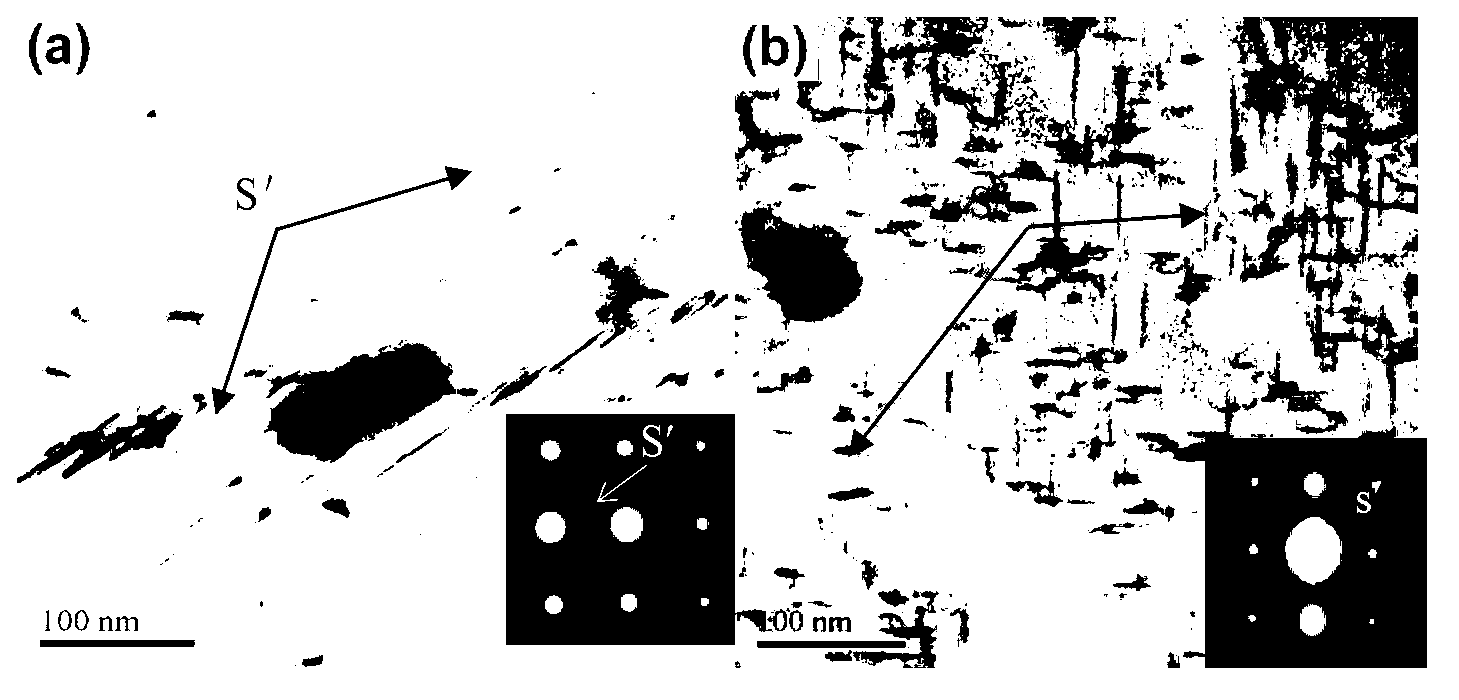

A technology of creep aging forming and al-cu-mg, which is applied in the field of heat treatment to improve the performance and anisotropy of creep-formed aluminum alloy sheets, and can solve the problem of uneven performance of components and difficulties in meeting the requirements of high-end equipment such as aerospace , the increase of the anisotropy degree of the alloy plate, etc., to achieve the effect of easy operation, improvement of alloy microstructure composition and mechanical properties, and reduction of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A adopts 490~505℃ solid solution for 50min~70min and then water quenching. After quenching, the plate is pre-stretched at 210%. The creep aging temperature is 150℃~200℃, the creep time is 2~12h, and the creep stress is 150MPa~300MPa. The pre-deformation treatment time should be strictly controlled within 4 hours.

Embodiment 2

[0028] B Use 490~505℃ salt bath furnace for solid solution for 40min~60min and then water quenching. After quenching, the plate is pre-stretched by 2-10%. The creep aging temperature is 150℃~200℃, and the creep time is 2~12h , The creep stress is 150MPa~300MPa. The pre-deformation treatment time should be strictly controlled within 4 hours.

Embodiment 3

[0030] C adopts 490~505℃ solid solution for 50min~70min and then water quenching. After quenching, the plate is pre-compressed by 2-10%. The creep aging temperature is 150℃~200℃, the creep time is 2~12h, and the creep stress 150MPa~300MPa. The pre-deformation treatment time should be strictly controlled within 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com