Intelligent robot welding monitoring system for holders of automotive child safety seats

A child safety seat and intelligent monitoring system technology, applied in welding equipment, comprehensive factory control, auxiliary welding equipment, etc., can solve the problems of unsatisfactory real-time and weld quality real-time control effects, and the inability to realize integrated control of welding torch trajectory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

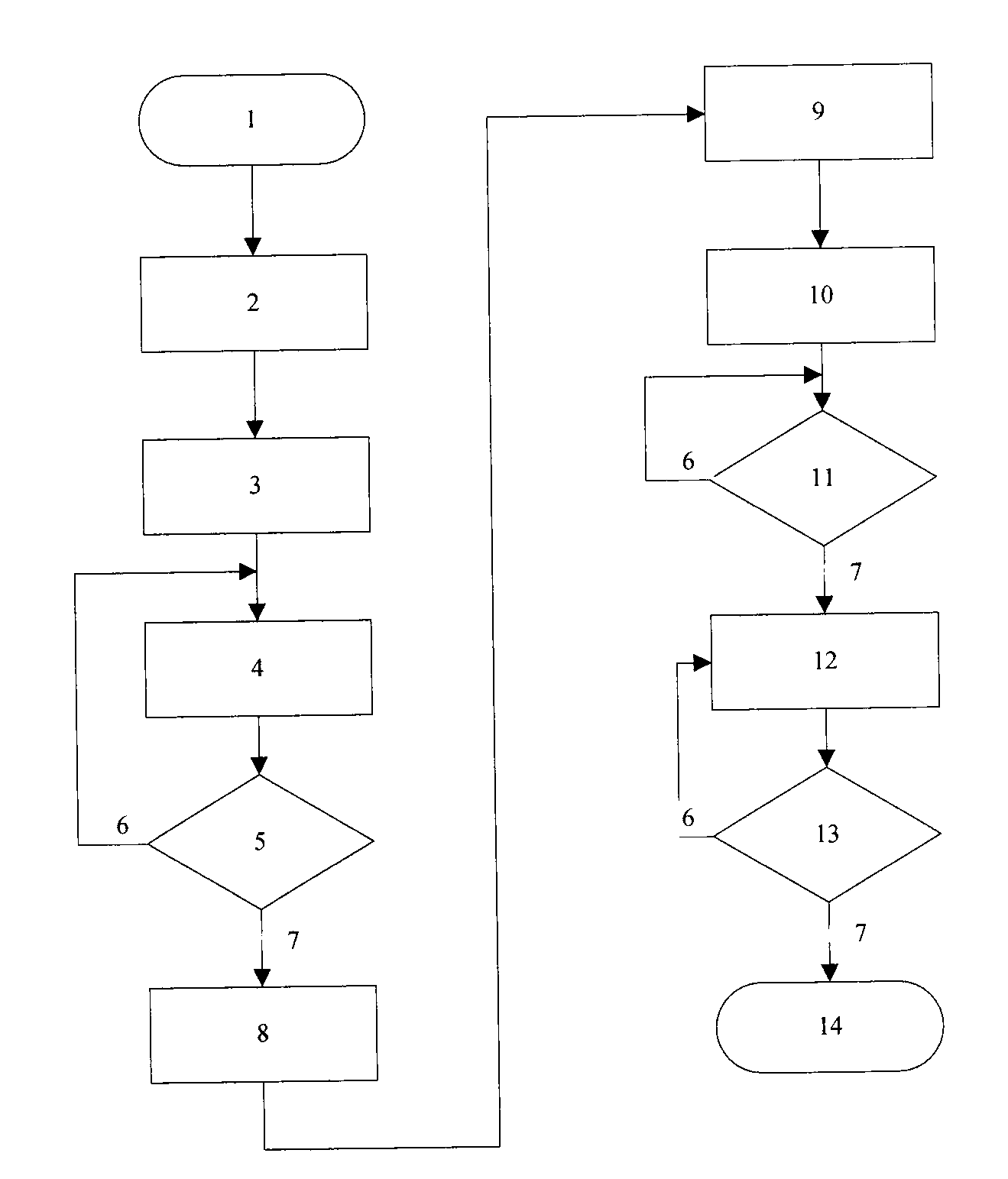

Method used

Image

Examples

Embodiment Construction

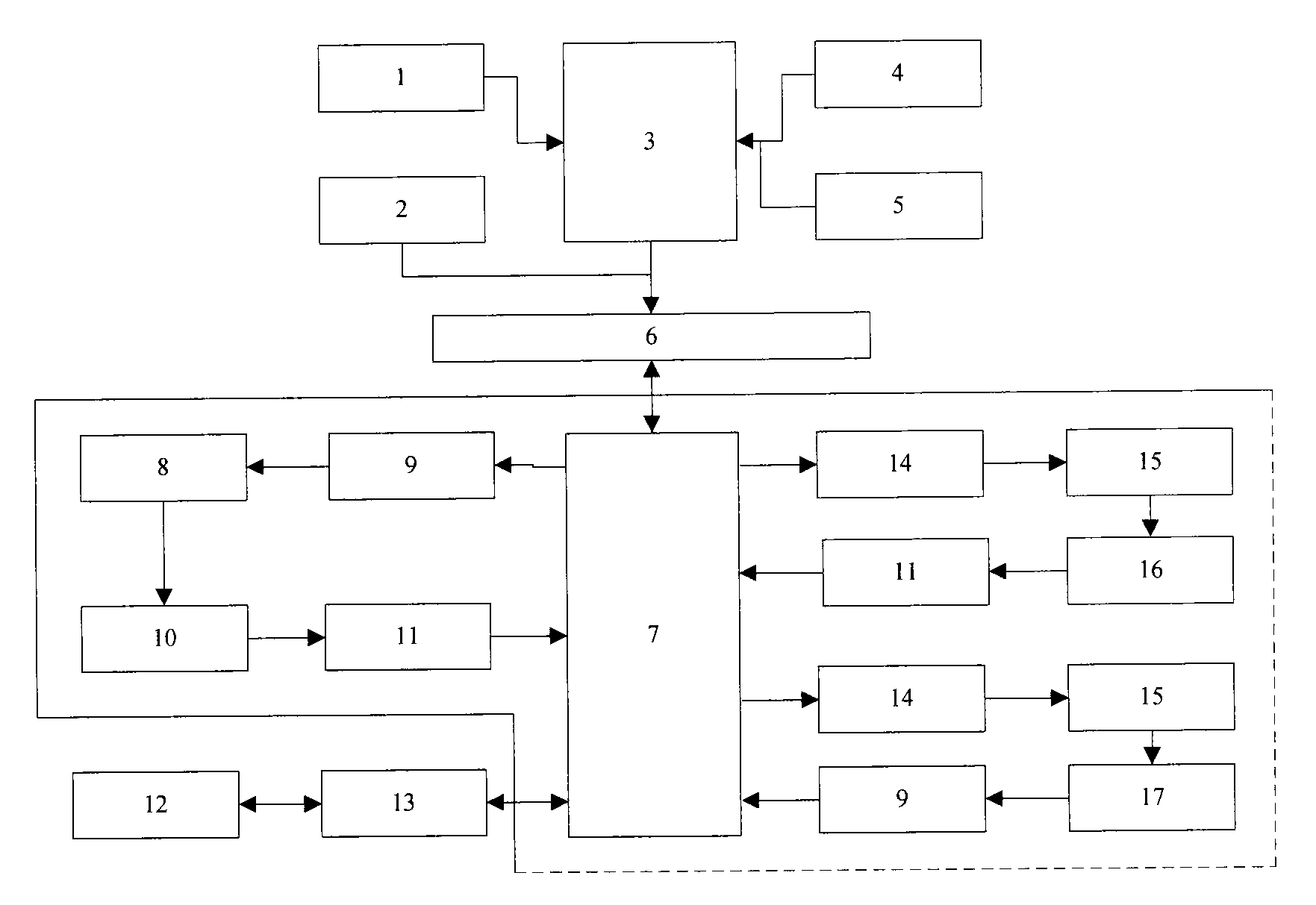

[0013] The joint drive unit in the hardware of the robot welding intelligent control system selects the P series AC servo motor with absolute encoder and the matching PY2 series servo amplifier (Servo Amplifier) as the drive device of the robot. This series of AC servo motors has a built-in absolute photoelectric encoder for feedback of the movement speed and position of each joint of the robot.

[0014] In the system control software, it mainly includes seven functional modules: system setting module, status monitoring module, motion control module, expert system module, data management module, online instruction module and communication module, which belong to data management programs and auxiliary programs. Does not communicate directly with external devices. The I / O state monitoring, PLC program, motion program and data acquisition and processing module in PMAC are developed based on PAMC language, and are programs that directly communicate with peripheral devices. Thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com