Junction field-effect transistor (JFET) pipe compatible process with double pole and P-ditch aligning automatically

A self-alignment and process technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as large parasitic capacitance and large manufacturing process deviation, and achieve large dynamic resistance, good consistency, offset and leakage. The effect of low current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

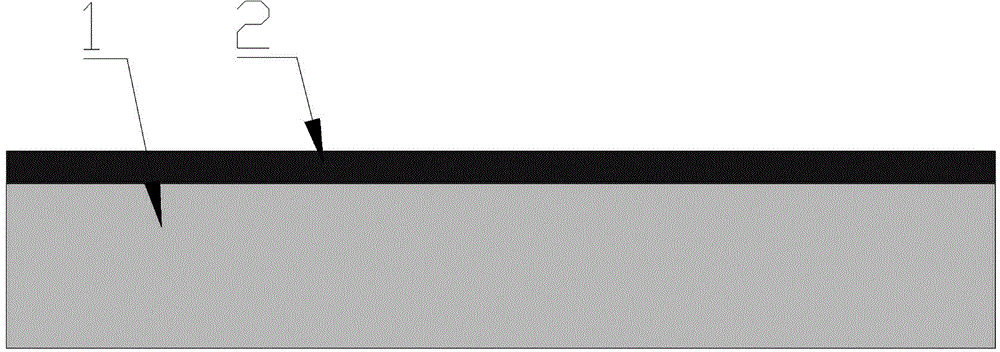

[0041] First, the substrate is selected as a P-type 4-inch silicon wafer, with a resistivity of (8-13) Ω.cm and a thickness of (525±20) μm; then the substrate is cleaned: the silicon wafer needs to be chemically cleaned, The cleaning chemicals are concentrated sulfuric acid, hydrogen peroxide and hydrofluoric acid. Concentrated sulfuric acid and hydrogen peroxide are strong oxidants that can remove particles or dust on the surface of silicon wafers. In the process of boiling concentrated sulfuric acid, a natural oxide layer will be formed on the surface of the silicon wafer, which needs to be rinsed with hydrofluoric acid, rinsed with high-purity deionized water, and centrifugally dried under nitrogen protection.

[0042] Proportion of chemical reagents and ambient temperature:

[0043] Sulfuric acid:hydrogen peroxide=3:1 temperature is (115±5)℃

[0044] Hydrofluoric acid: water = 1:30 temperature is room temperature

[0045] Deionized water resistivity ≥ 18MΩ.cm.

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com