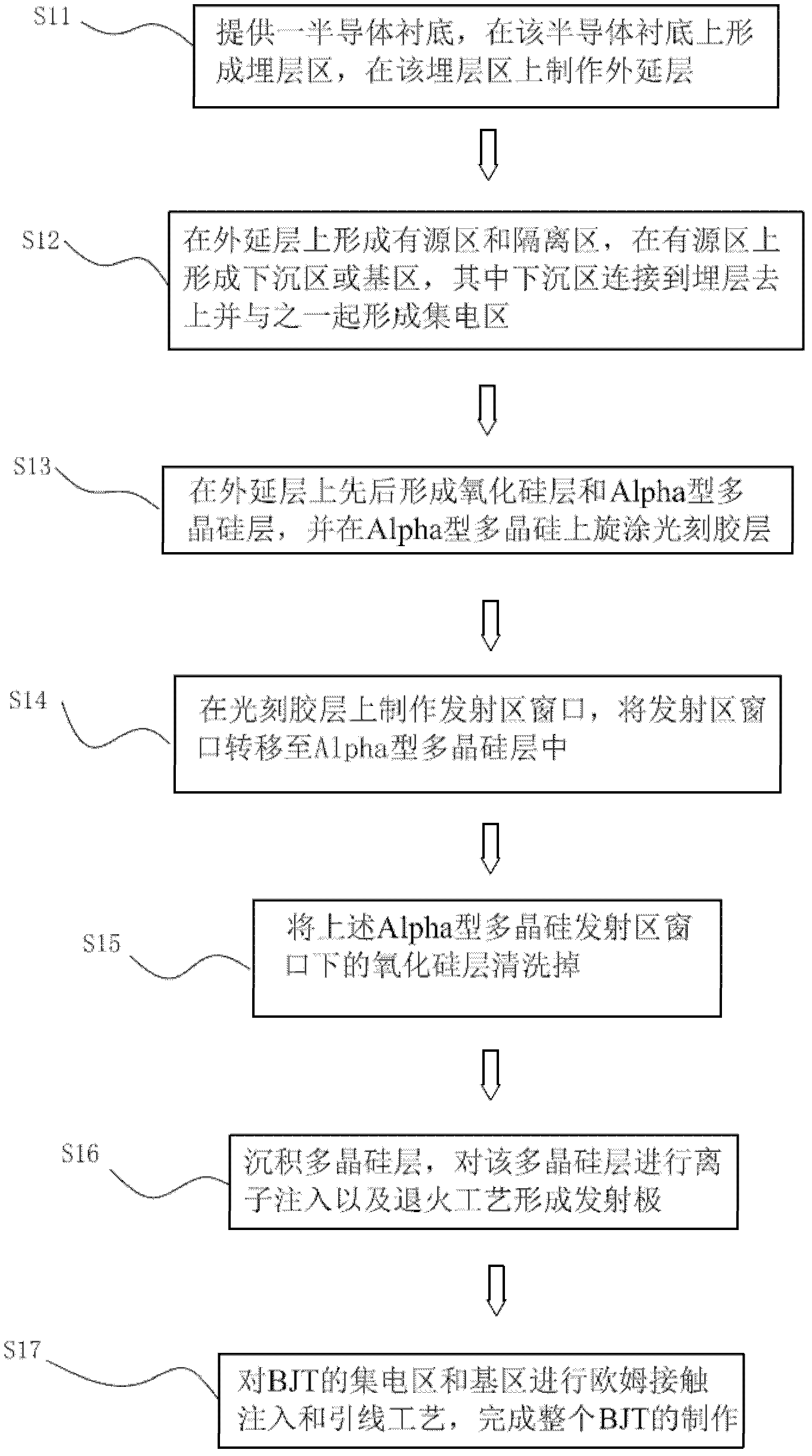

Method for manufacturing BJT (bipolar junction transistor) and BiCMOS (bipolar complementary metal oxide semiconductor)

A manufacturing method and transistor technology, applied in semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve problems such as ineffective effects, serious surface recombination of emission regions, and influence on CMOS devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

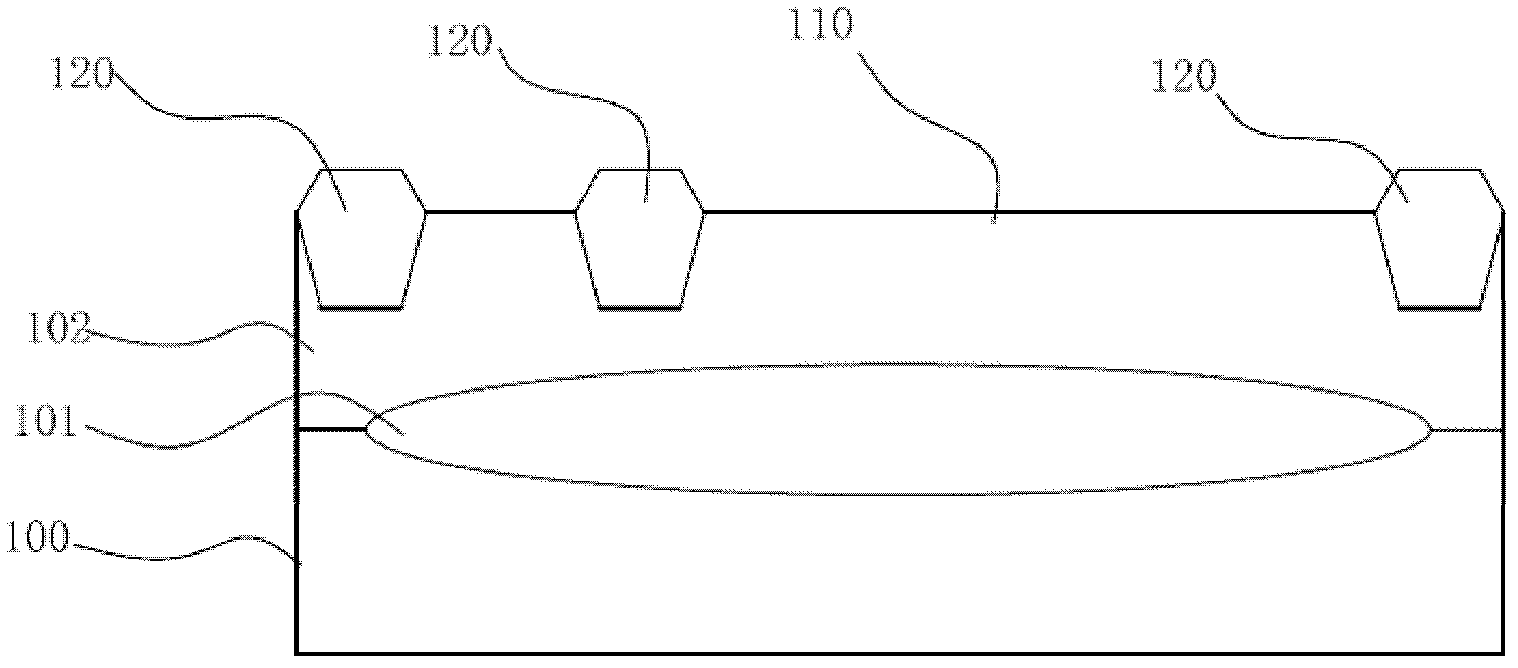

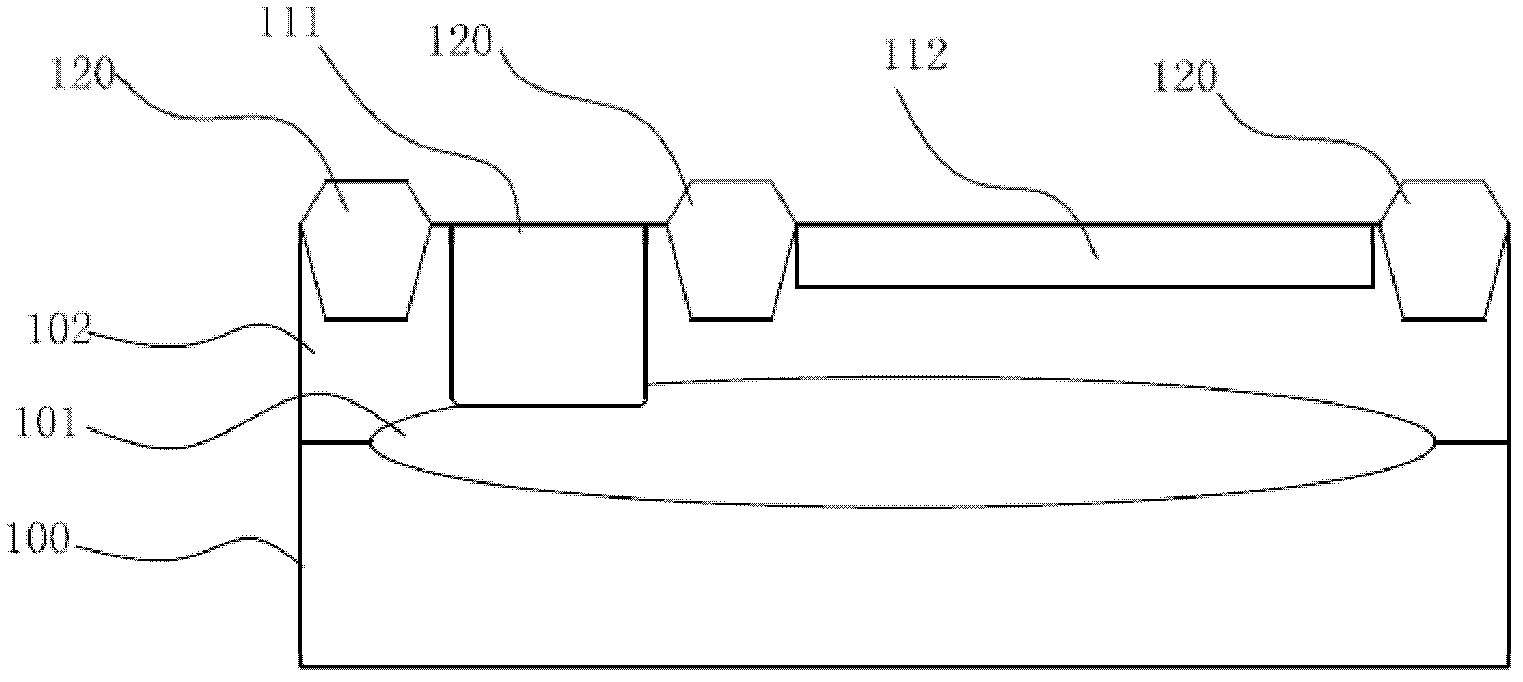

[0043]As introduced in the background technology, in the existing BiCMOS process, there are two main problems when making the emitter of the BJT: first, when the emitter window is formed by dry etching, due to the impact of etching ions on the single crystal silicon The damage on the surface is relatively large, which makes the surface shape of the single crystal silicon poor, and the phenomenon of recombination with the surface of polysilicon subsequently deposited on the single crystal silicon is serious, resulting in poor small current amplification characteristics of the BJT. Second, because in the existing process, the ion implantation process and annealing process of making the BJT emitter and the source and drain of the CMOS are carried out at the same time, so the junction depth formed by the emitter is relatively large and the ion concentration on the surface is also low. It will be very high, and it will also greatly limit the design flexibility of BJT and CMOS.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com