Flow control method and apparatus for a continuous multiple zone mass transfer

A technology of mass transfer and equipment used in the preparation/purification of sulfur, separation methods, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

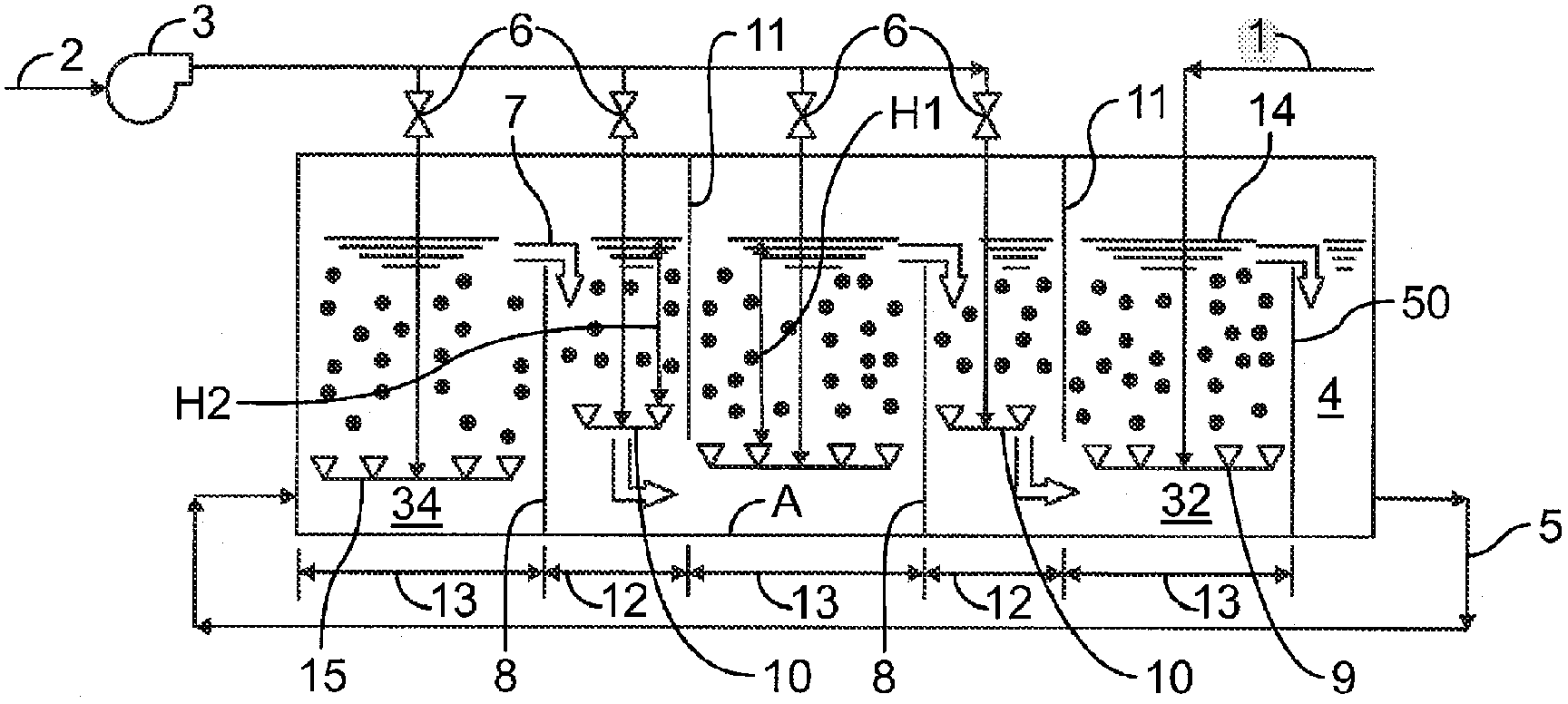

[0035] Now turn to the attached picture and first go to the figure 1 , illustrates an embodiment of the invention showing a gas distributor 10 inserted into one or more downcomers 12 connecting two mass transfer zones 13 . The distributor 10 is located above the bottom of the weir 11 . The gas is then injected into the sparger 10 . As the amount of injected gas increases, the gas-filled density of the liquid in the downcomer 12 will approach the gas-filled density of the liquid in the mass transfer zone 13 . The distributor 10 may be inserted into a downcomer 12 that separates two or more oxidation mass transfer zones and / or two or more process gas mass transfer zones. Below is an explanation of how the device controls the flow of the solution.

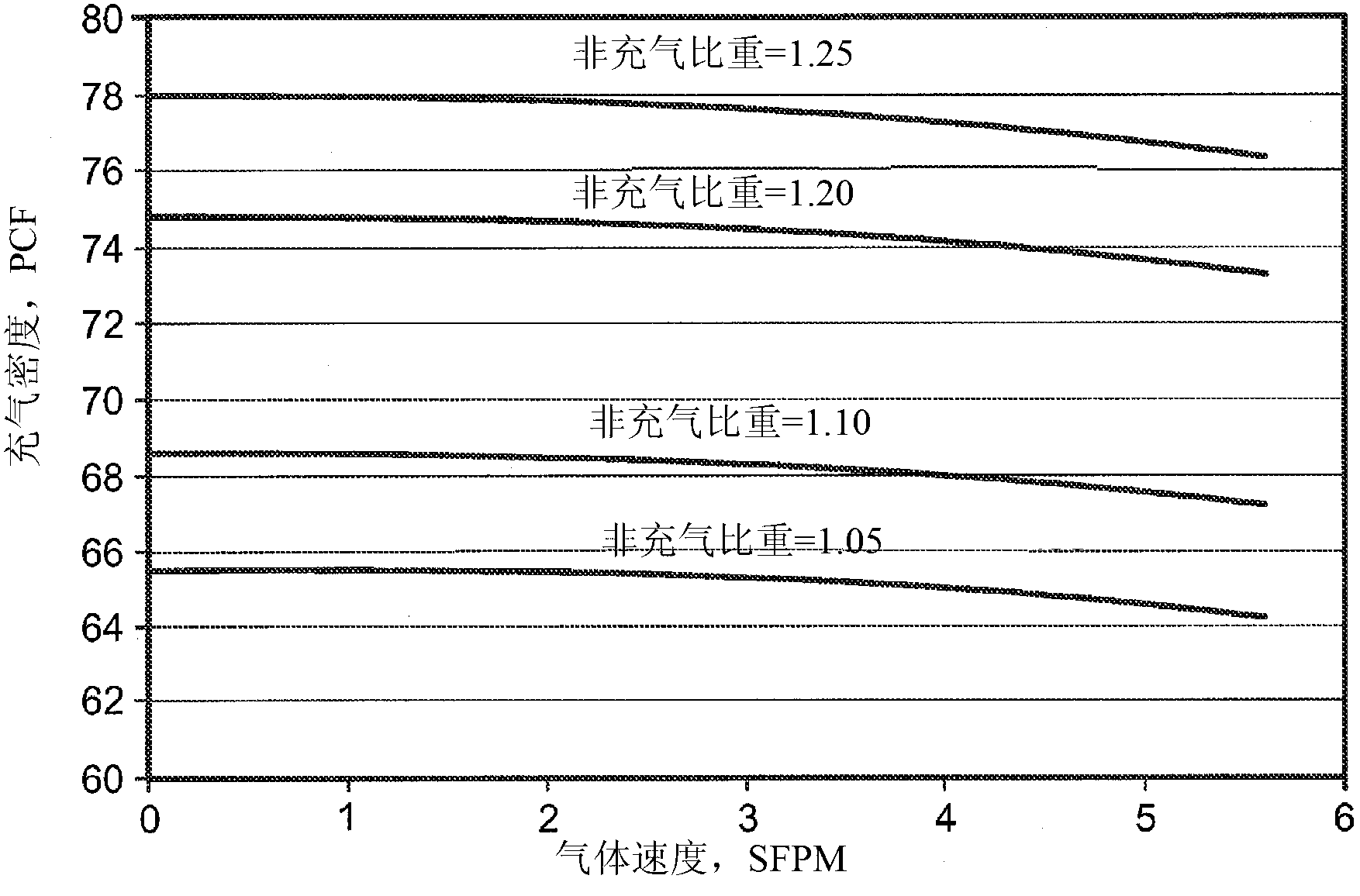

[0036] As mentioned above, the density of an aerated solution varies directly with the non-aerated density of the solution and inversely with the velocity of the gas passing through the solution. In other words, the higher the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com