Method for eliminating residual solution during etching for capacitive touch screen

A capacitive touch screen and a touch screen technology are applied in the field of eliminating the etching residual solution of the capacitive touch screen and eliminating the residual solution, which can solve the problems such as the etching solution affecting the product quality, and achieve the effects of high production efficiency, simple method and product quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

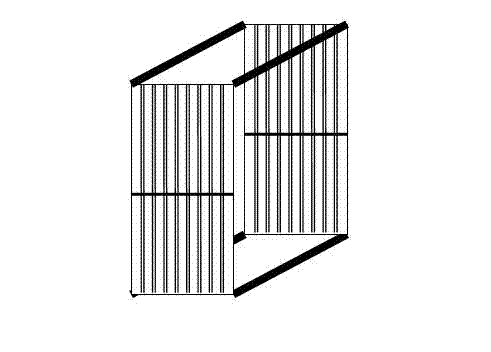

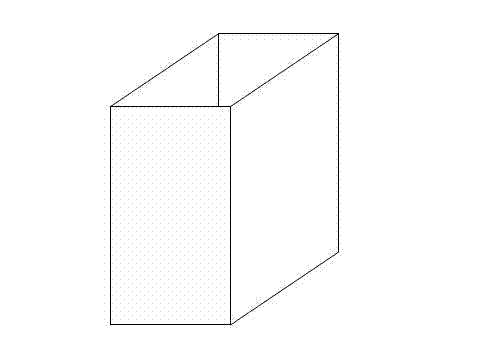

[0021] Such as Figure 1-2 shown.

[0022] A method for eliminating etching residual solution of capacitive touch screen, it comprises the following steps:

[0023] First, place the etched touch screen hanger on the figure 1 on the bracket shown, and place the bracket in 90 seconds figure 2 In the shown soaking tank filled with cleaning liquid, the liquid level of the cleaning liquid in the soaking tank should be higher than the effective working area of the touch screen;

[0024] Secondly, the touch screen is soaked in the soaking box for 25 to 35 minutes, then taken out and immediately enters the next process;

[0025] The weight percentage of the cleaning solution is: 0.8-1% HCl, 0.05%-0.07% HNO 3 and the remainder of deionized water.

[0026] Stent and solution do not react. During production, the ITO glass substrate produced in ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com