Deflashing device for wheel blank

A technology for deburring and blanking, which is applied to the field of deburring devices for wheel blanks, can solve the problems of the influence of machining positioning accuracy, high labor intensity, increased cost, etc., so as to improve the positioning accuracy of clamping, processing efficiency, and high degree of automation. , safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

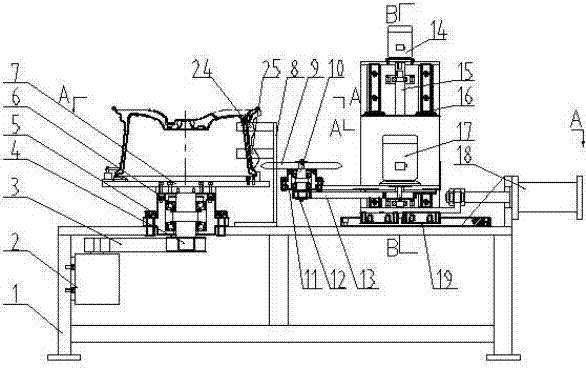

[0014] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

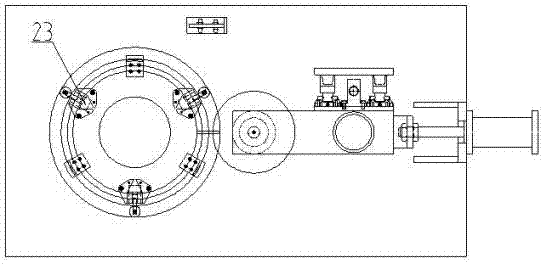

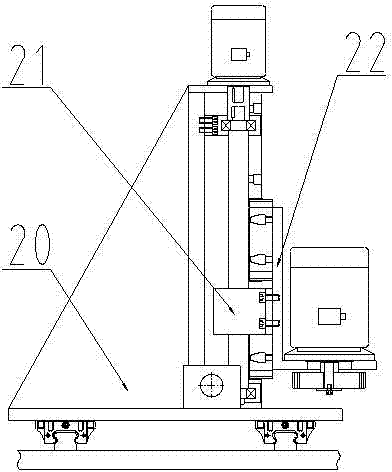

[0015] The device consists of frame 1, servo motor 2. Timing belt 3. Shaft 4. Bearing seat 5. Bearing 6. Chuck 7, bracket 8, grinding wheel 9, shaft 10. Bearing seat 11. Bearing 12. Timing belt 13. Servo motor 14. Lead screw 15. Lifting guide rail 16. Servo motor 17. Servo electric cylinder 18, translation guide rail 19, translation support 20, lead screw nut 21, lifting support 22, fixture 23 and photoelectric switch 24 and photoelectric consecration 25 composed of chuck 7 and clamp 23 through shaft 4. Bearing seat 5. Bearing 6 is fixed on the top of rack 1, the servo motor 2 is fixed on the left side of frame 1, through the timing belt 3 driving shaft 4 and the chuck 7 rotate; the translation support 20 is fixed on the right side of the frame 1 top by the transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com