Automatic optical detection laser welding system

An automatic optical detection and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as eye fatigue, easy corrosion of PCB board surface, continuous welding, etc., to improve work efficiency and reduce defects. phenomenon, the effect of reducing the vulnerability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

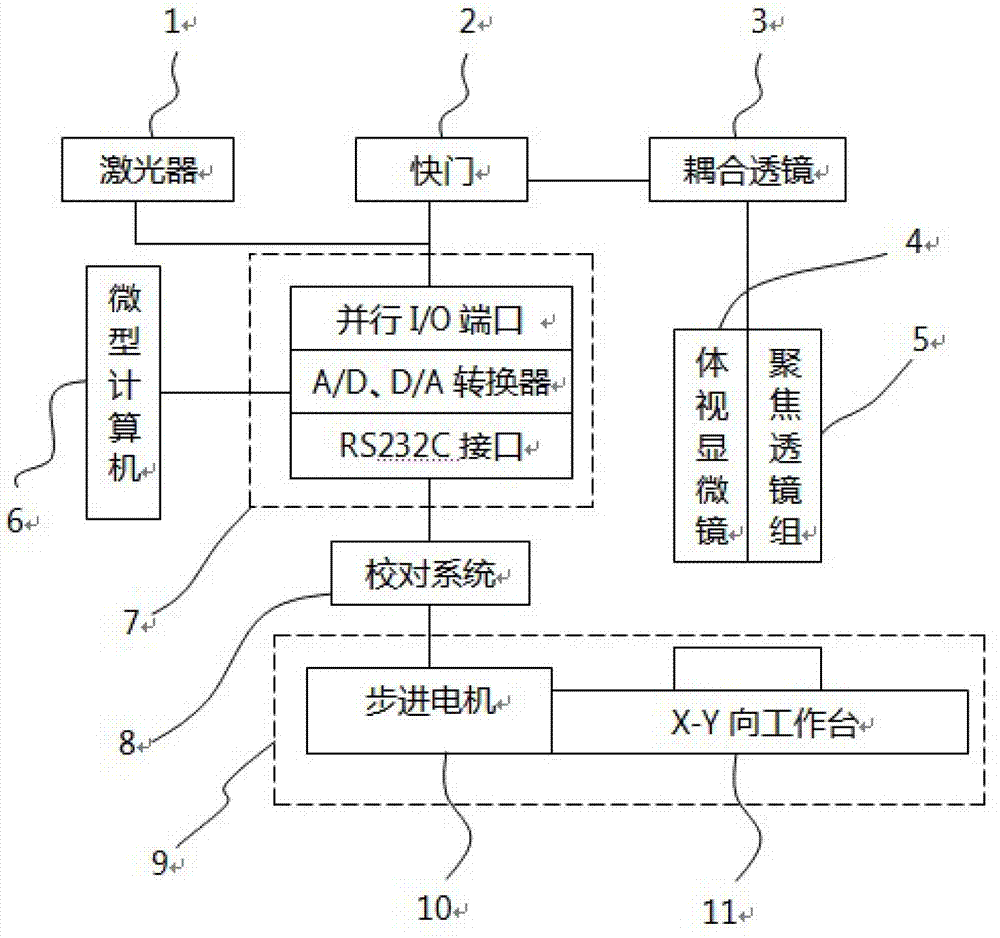

[0015] refer to figure 1 Shown is a schematic block diagram of the automatic optical inspection laser welding system of the present invention, the system is composed of an automatic optical inspection system (AOI system) and a laser welding system, wherein the automatic optical inspection system includes a microcomputer 6, a graphic sampling system ( Including shutter 2 and stereo microscope 4), data conversion system 7, proofreading system 8 and automatic workbench 9, the laser welding system includes laser 1, coupling lens 3 and focusing lens group 5. In this embodiment, the system uses a fiber laser with a wavelength of 980nm or 808nm.

[0016] The data conversion system 7 is loaded in the microcomputer 6, and between it and the microcomputer 6, various calculation pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com