Continuous preparation method of tungsten carbide powder

A technology of tungsten carbide and powder, which is applied in the field of continuous preparation of tungsten carbide powder, can solve the problems that affect the consistency of performance indicators and quality stability of coarse-grained tungsten carbide powder, low compactness inside the crystal, uneven temperature, etc., and achieve consistent improvement The effects of stability and quality stability, reduction of hole duty ratio, and prolongation of heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

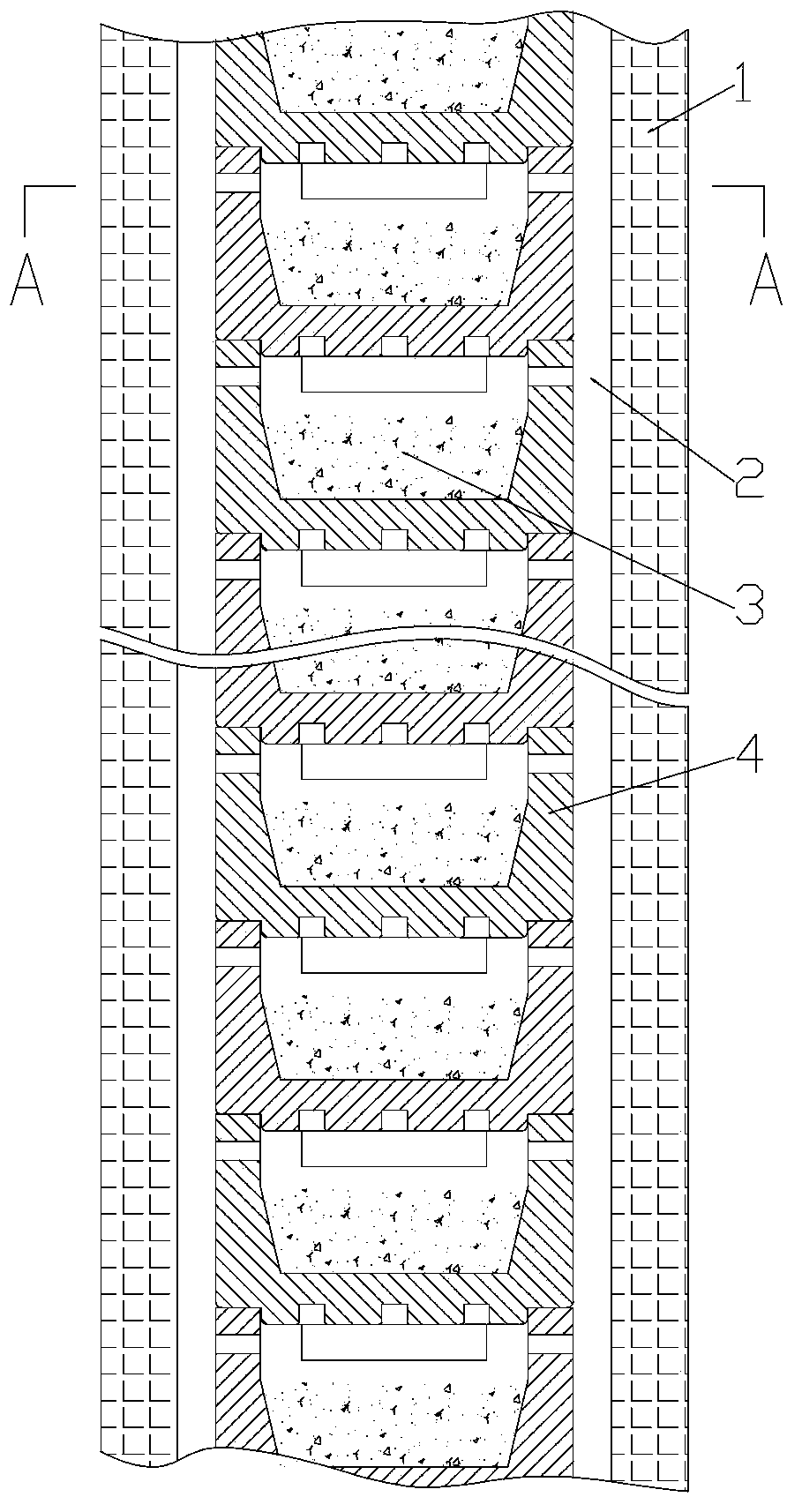

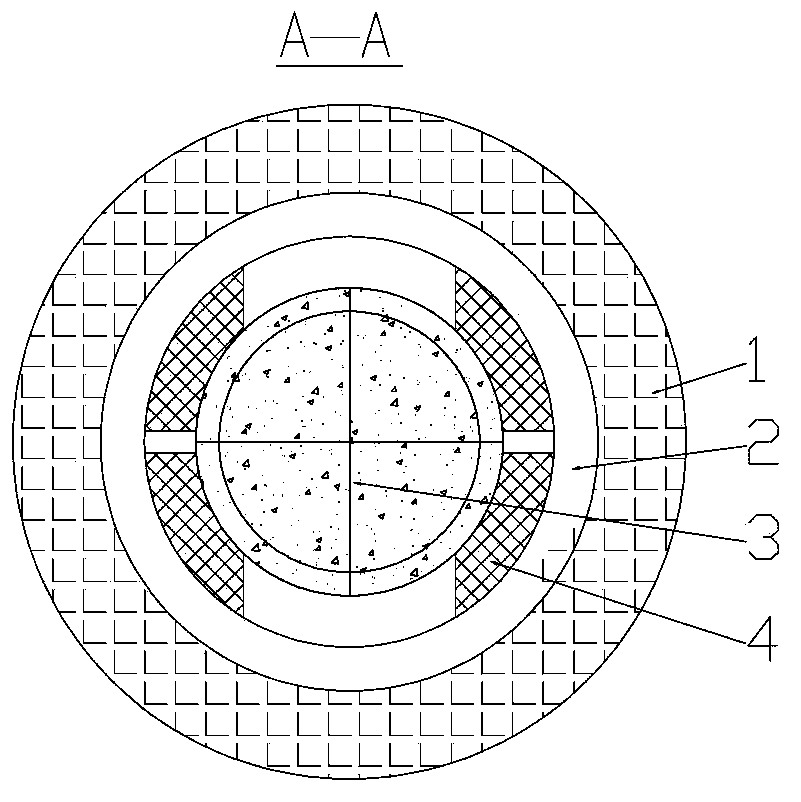

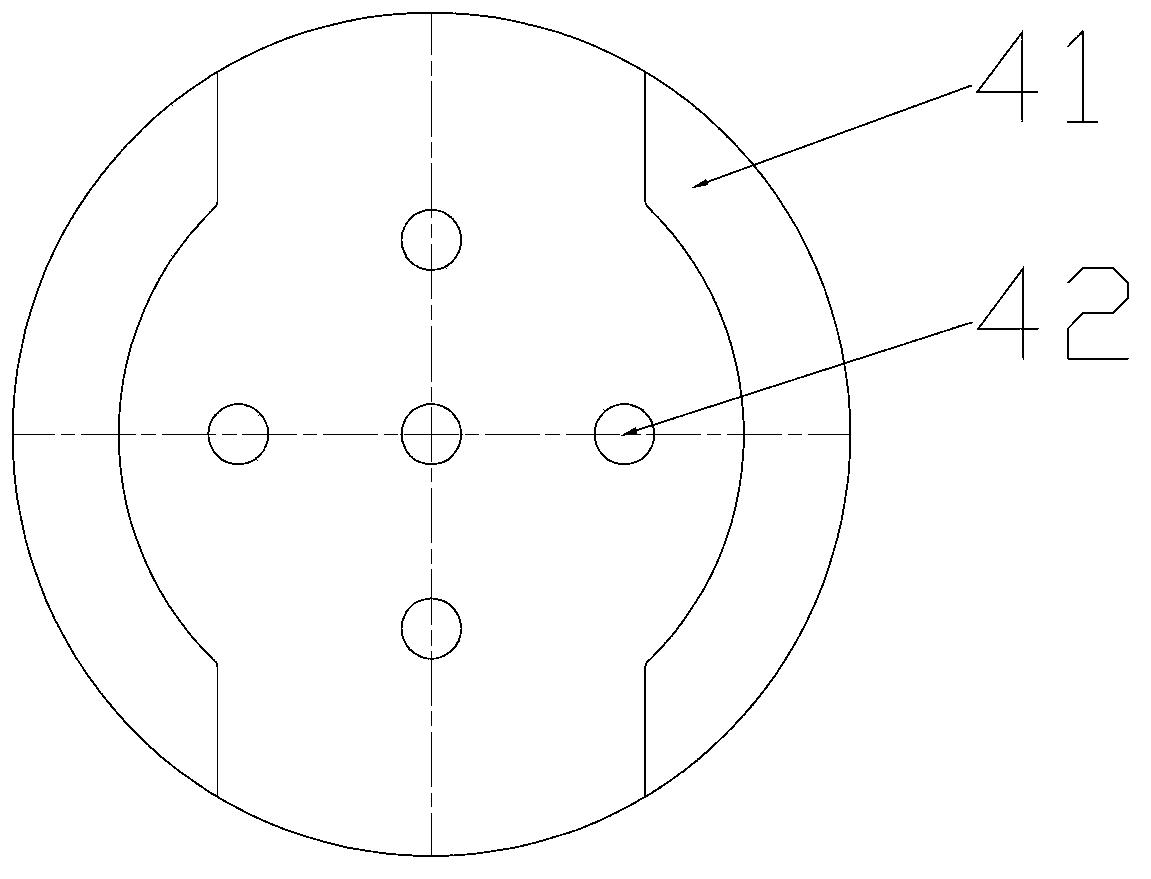

Image

Examples

Embodiment 1

[0038] Tungsten powder with Fsss particle size of 16-22 microns and metallurgical carbon black are uniformly mixed. After the mixture is loaded into a boat, it enters an ultra-high temperature induction heating vertical continuous carbonization furnace for carbonization heating. The heating temperature is 2500 °C and the heating time is 3 hours. The gas is nitrogen, and the boat is released about 6 hours after entering the carbonization furnace, and the temperature of the discharge is less than 60 °C;

[0039] Observation of the shape of the baked product: the tungsten carbide product in the boat is a loose block, which can be easily crushed into powder by hand (if it is a product burned with hydrogen, the block in the boat is very hard, and it can be crushed with a It is impossible to crush it by hand, and it must be crushed mechanically), and the powder color is uniform, which shows that the carbonization reaction is relatively peaceful under the ultra-high temperature + nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com