Method for preparing micro-nano TATB (triamino trinitrobenzene) explosive granules

A micro-nano and explosive technology, applied in the field of material science, can solve the problems of TATB insensitivity and limitation, and achieve the effect of simple operation and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

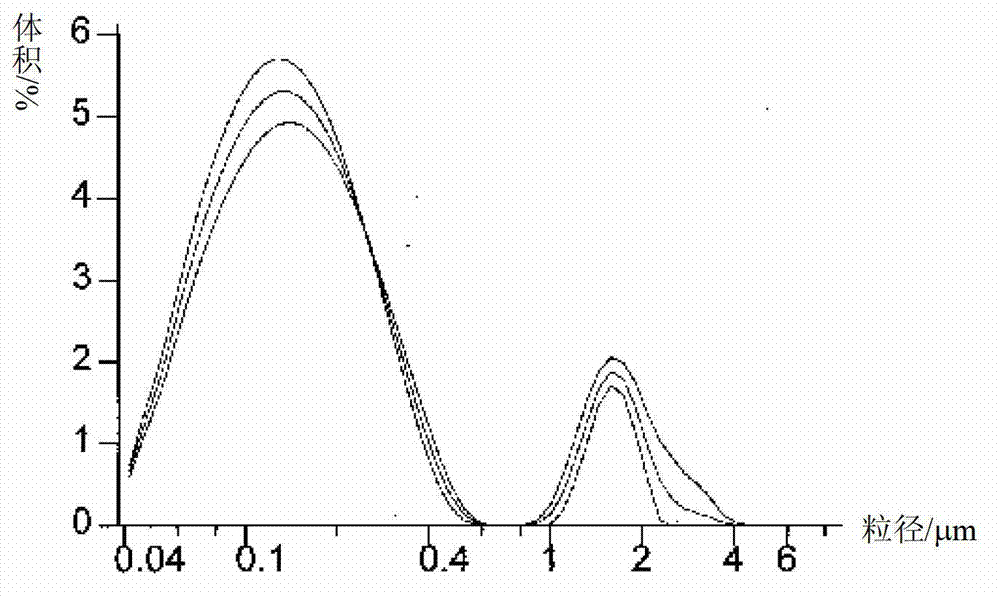

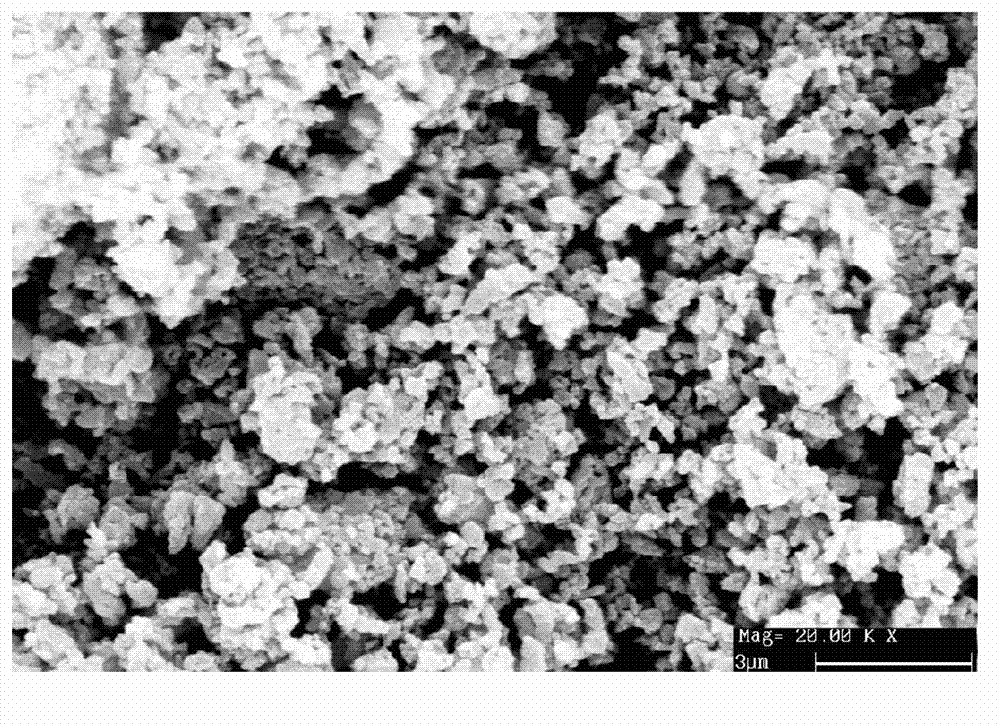

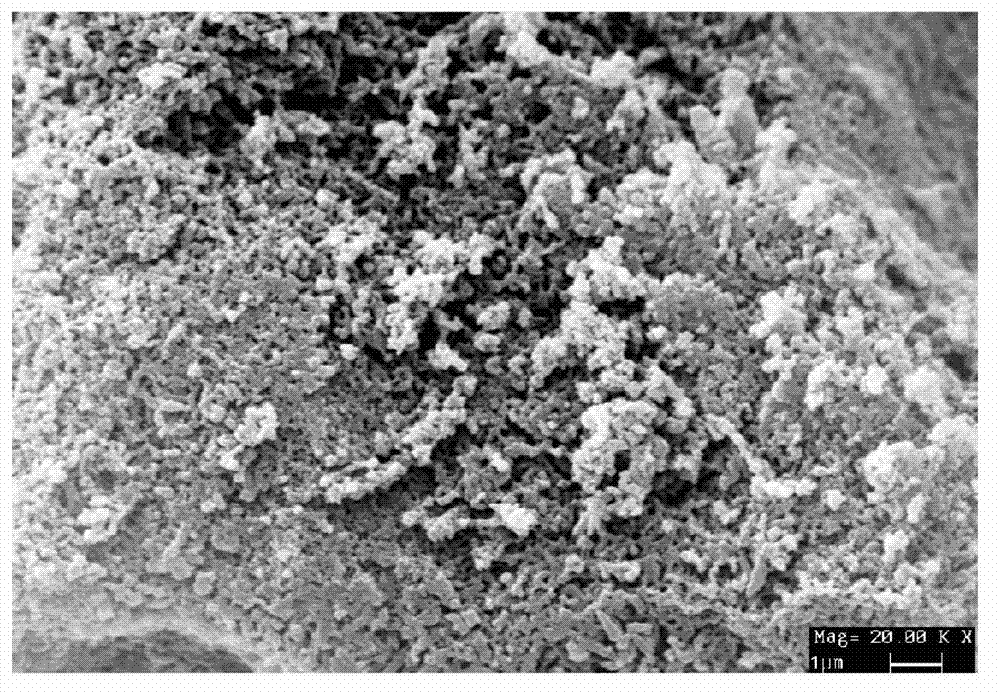

[0026] Add 4000g of deionized water and 1.0g of OP-10 into the crystallizer and mix well, pre-cool to 2°C for later use; at room temperature, add 100g of TATB and 2000g of concentrated sulfuric acid into the drug-dissolving kettle, stir to completely dissolve the explosive, remove the stirring , transfer the explosive solution to the liquid medicine tank; use a stirrer to make the non-solvent medium in the crystallizer run vigorously, then add the explosive solution in the liquid medicine tank to the non-solvent dropwise under normal pressure, and add ice while dropping Block, keep the temperature of the non-solvent medium at about 2°C; the obtained fine material liquid is washed several times, centrifuged at 10,000r / min, and finally freeze-dried at -45°C to obtain 92g of micro-nano TATB explosives, the volume average particle size Diameter 171nm, d 50 =107nm.

Embodiment 2

[0028] Add 4000g of deionized water and 1.0g of OP-10 into the crystallizer and mix well, pre-cool to 2°C for later use; at room temperature, add 100g of TATB and 1000g of concentrated sulfuric acid into the drug-dissolving kettle, stir to completely dissolve the explosive, remove the stirring , transfer the explosive solution to the liquid medicine tank; use a stirrer to make the non-solvent medium in the crystallizer run vigorously, then add the explosive solution in the liquid medicine tank to the non-solvent dropwise under normal pressure, and add ice while dropping block, keeping the temperature of the non-solvent medium at about 2°C; the obtained fine material liquid was washed several times, centrifuged at 10,000r / min, and finally freeze-dried at -45°C to obtain 91g of micro-nano TATB explosives, the volume average particle size Diameter 922nm, d 50 =2591nm.

Embodiment 3

[0030] Add 4000g of deionized water and 1.0g of OP-10 into the crystallizer and mix well, pre-cool to 10°C for later use; at room temperature, add 100g of TATB and 2000g of concentrated sulfuric acid into the drug-dissolving kettle, stir to completely dissolve the explosive, remove the stirring , transfer the explosive solution to the liquid medicine tank; use a stirrer to make the non-solvent medium in the crystallizer run vigorously, then add the explosive solution in the liquid medicine tank to the non-solvent dropwise under normal pressure, and add ice while dropping Block, keep the temperature of the non-solvent medium at about 10°C; the obtained fine material liquid is washed several times, centrifuged at 10,000r / min, and finally freeze-dried at -40°C to obtain 90g of micro-nano TATB explosives, the volume average particle size Diameter 1769nm, d 50 =1531nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com