Patents

Literature

38 results about "Trinitrobenzenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic promotive phosphating liquor as well as preparation method and use thereof

InactiveCN101457355AImprove protectionWide range of processingMetallic material coating processesSodium tetrafluoroboratePhosphoric acid

The invention provides an organic promoting phosphating solution, a preparation method thereof and the application thereof; wherein, the phosphating solution comprises basic solution and an accelerant which have the weight ratio of 1.5-2.5:1; the basic solution is the mixture of iron powders, phosphoric acid, zinc oxide, hydrofluoric acid, carbonate, fluosilicic acid and water; the accelerant is the mixture of sodium fluoborate, tartaric acid, sodium chlorate, caustic soda, trinitrobenzene sulfonic acid and water. The phosphating solution has wide phosphating process, can be used within the temperature of 5-65 DEG C, is suitable for the treatment before coating of automobiles, electric apparatuses, furniture and mechanical equipment, has simple production and use methods and meets the requirement of environmental protection.

Owner:DONGGUAN YINGMING CHEM ENG

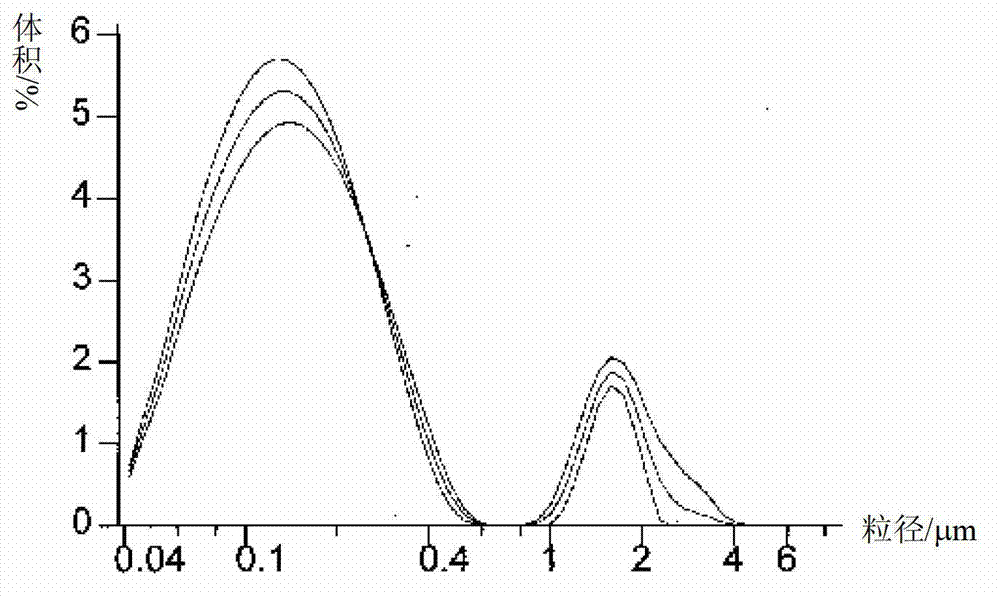

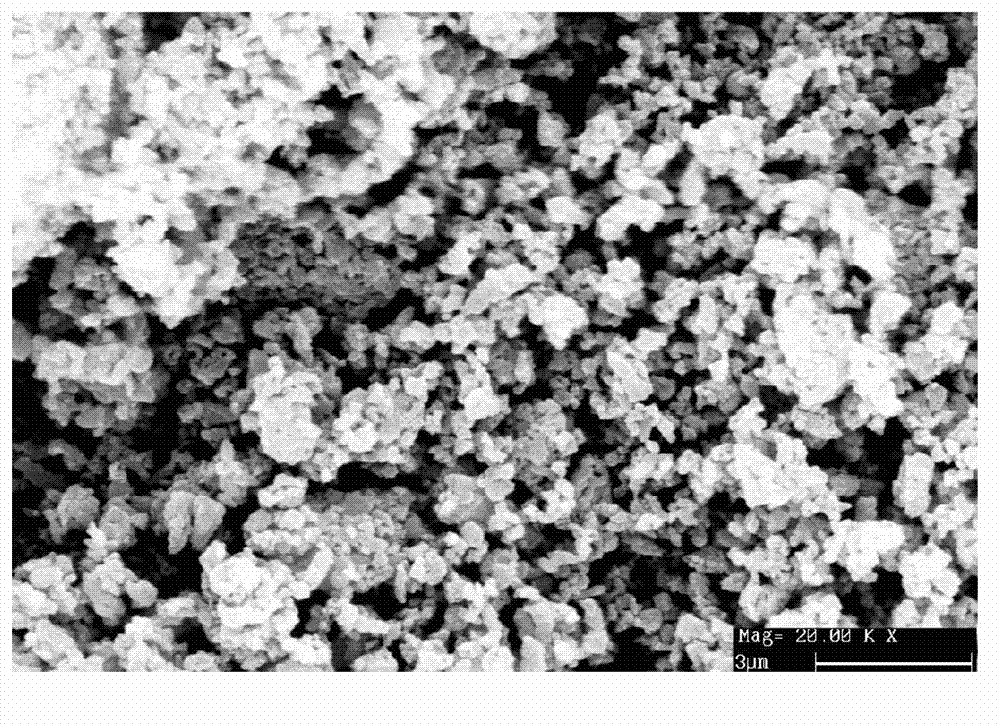

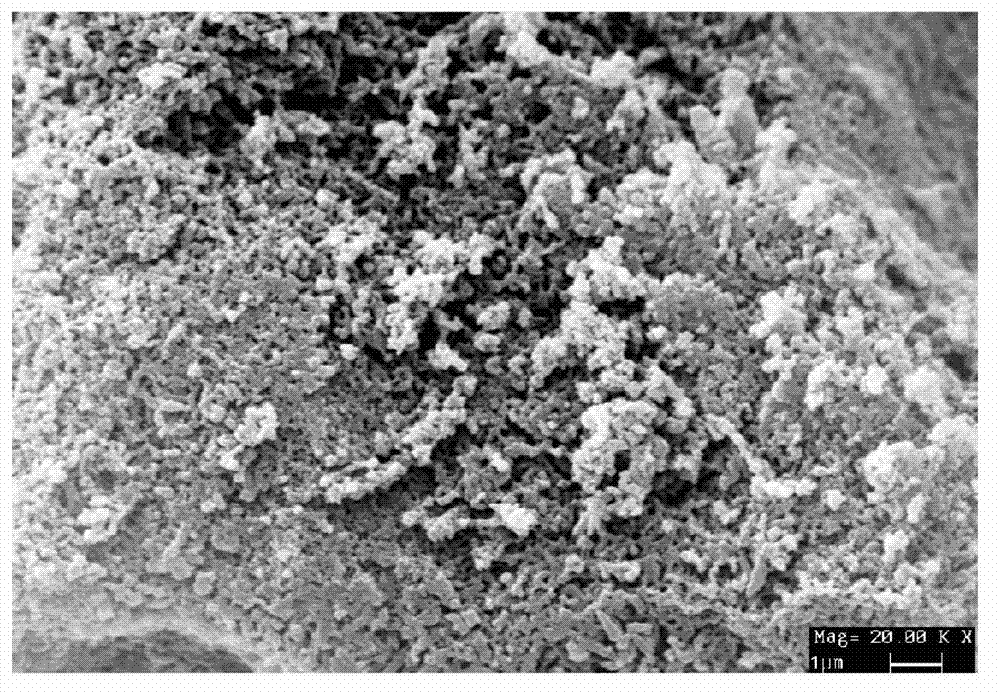

Method for preparing micro-nano TATB (triamino trinitrobenzene) explosive granules

InactiveCN102924192ASimple processSimple and fast operationExplosive working-up apparatusNitrated aromatic explosive compositionsMicro nanoNon solvent

The invention discloses a method for preparing micro-nano TATB (triamino trinitrobenzene) explosive granules. The method comprises the following steps of: (1) preparation of explosive solution, wherein the TATB explosive is dissolved to prepare the explosive solution without impurities; (2) preparation of non-solvent medium, wherein water and dispersant are uniformly mixed to prepare the non-solvent medium, and the non-solvent medium is cooled by putting in a refrigerator or adding ice cakes and other mode; (3) mixed crystallization, wherein the TATB explosive solution prepared in the step (1) and the non-solvent medium prepared in the step are mixed to crystallize to form micro-nano explosive granules, and the non-solvent medium in the mixing process is kept at a temperature of lower than 10 DEG C; and (4) post-treatment, wherein the micro-nano explosive granule liquid prepared in the step (3) are subjected to solid-liquid separation, washing purification and drying to obtain the micro-nano TATB explosive product. The method has the characteristics of simple process flow and convenience in operation, and is applicable to industrial large-scale production. By adopting the method, micro-nano TATB powder with average granular diameter of 170nm and d50 of 100nm can be obtained by controlling process parameters.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

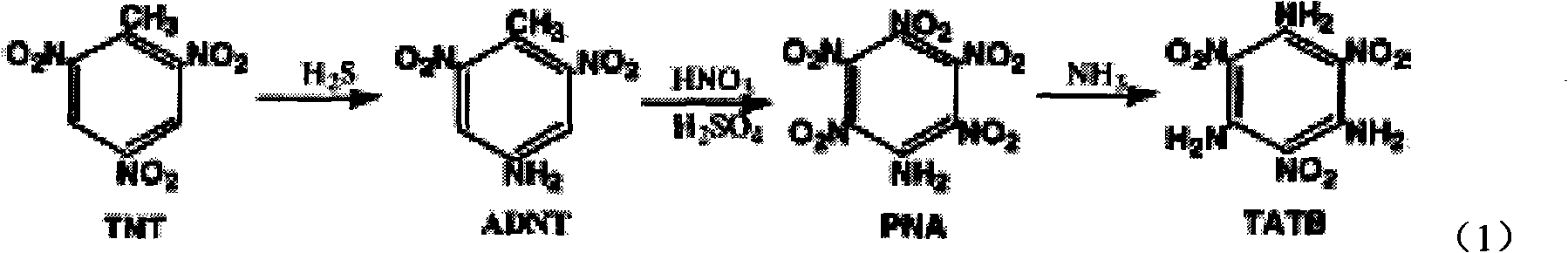

Method for synthesizing tri-amino trinitrobenzene (TATB) by trinitrotoluene (TNT)

InactiveCN101982454AAvoid pollutionIncrease concentrationAmino preparation by hydrogen substitutionOrganic synthesisSolvent

The invention relates to a method for synthesizing tri-amino trinitrobenzene (TATB) by trinitrotoluene (TNT), belonging to the field of organic synthesis technology. The method comprises the following steps of: dissolving the TNT into the concentrated nitric acid, heating up, adding the saturated water solution of the sodium chlorate, reacting, cooling and filtering to obtain the TNBA; adding the TNBA into the water, stirring, adding the sodium hydroxide water solution, filtering, heating up the filter liquor to perform the decarboxylation reaction, cooling, filtering and drying to obtain the TNB; dissolving the TNB into reagent, adding the TNB into turbid liquid mixed by the ammoniation reagent, the sodium methylate and the reagent, and stirring; and heating up, cooling after the reaction, pouring into the distilled water, adjusting the PH value to be neutral or weakly acidic by the acetic acid, stewing, filtering in a pumping way, washing with water, and drying to obtain the TATB. The method takes the TNT as the raw material and uses the chrome-free technology in the oxidizing reaction to avoid the environment pollution, uses a small quantity of the reagent during the aminating reaction to increase the concentration of the reactant and optimize the dynamic conditions, and uses a small quantity of the ammoniation reagent and the sodium methylate to reduce the cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

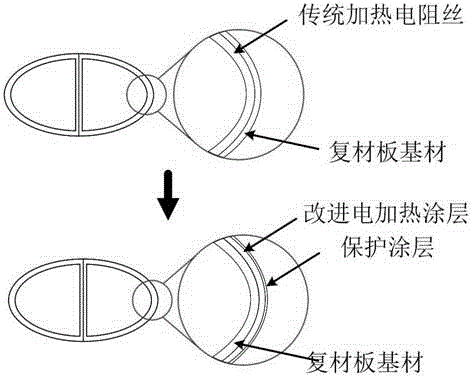

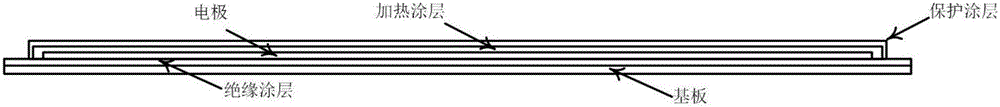

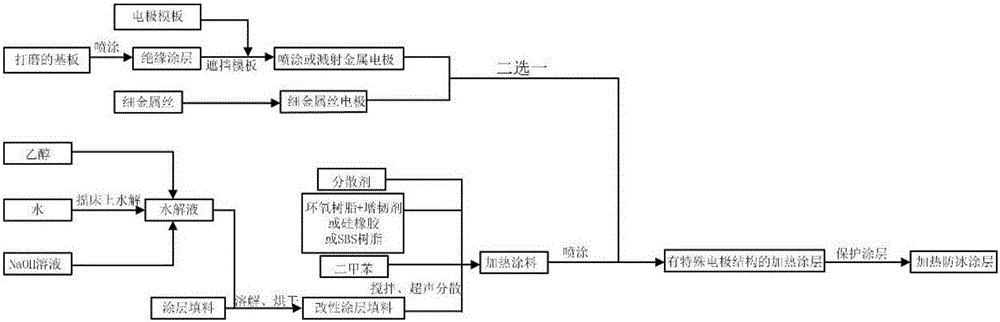

Electric-heating anti-icing coating and preparation method thereof

InactiveCN106111499AHeating evenlyReduce temperature requirementsChemical industryPretreated surfacesElectricityHydrolysate

The invention provides an electric-heating anti-icing coating. The electric-heating anti-icing coating is structurally formed through the steps that firstly, an insulating coating is sprayed onto a substrate, so that insulation and heat insulation from the substrate are achieved; secondly, an electrode is manufactured on the insulating coating so that heating can be more uniform; thirdly, electric-heating paint is sprayed onto the electrode; and finally, a protective coating is sprayed onto the outermost layer. A preparation method of the electric-heating anti-icing coating comprises the following steps that firstly, a coupling agent is placed on a table concentrator for hydrolysis, so that hydrolysate is obtained; and heating coating filler is added into the hydrolysate to be soaked and modified and then is dried, so that modified heating coating filler is obtained; secondly, a heating coating base material is placed in a beaker to be diluted with xylene, and dispersing agents such as trinitrobenzene are added, so that a heating coating base body diluent is obtained; and thirdly, the heating coating filler is added into the heating coating base body diluent, evenly stirred and placed into an ultrasonic cleaning machine for ultrasonic dispersion for 15 minutes, so that the required electric-heating coating is obtained. According to the coating, energy consumption is low, heating is uniform, the manufacturability is good, and the purpose of preventing and removing ice can be achieved.

Owner:BEIHANG UNIV

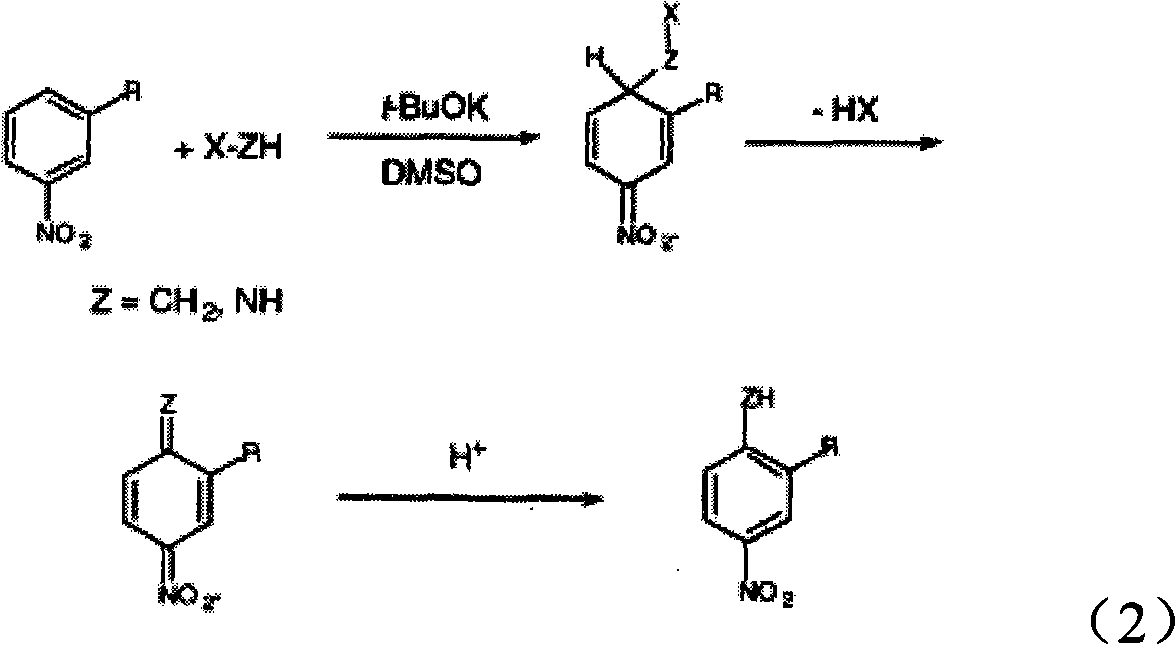

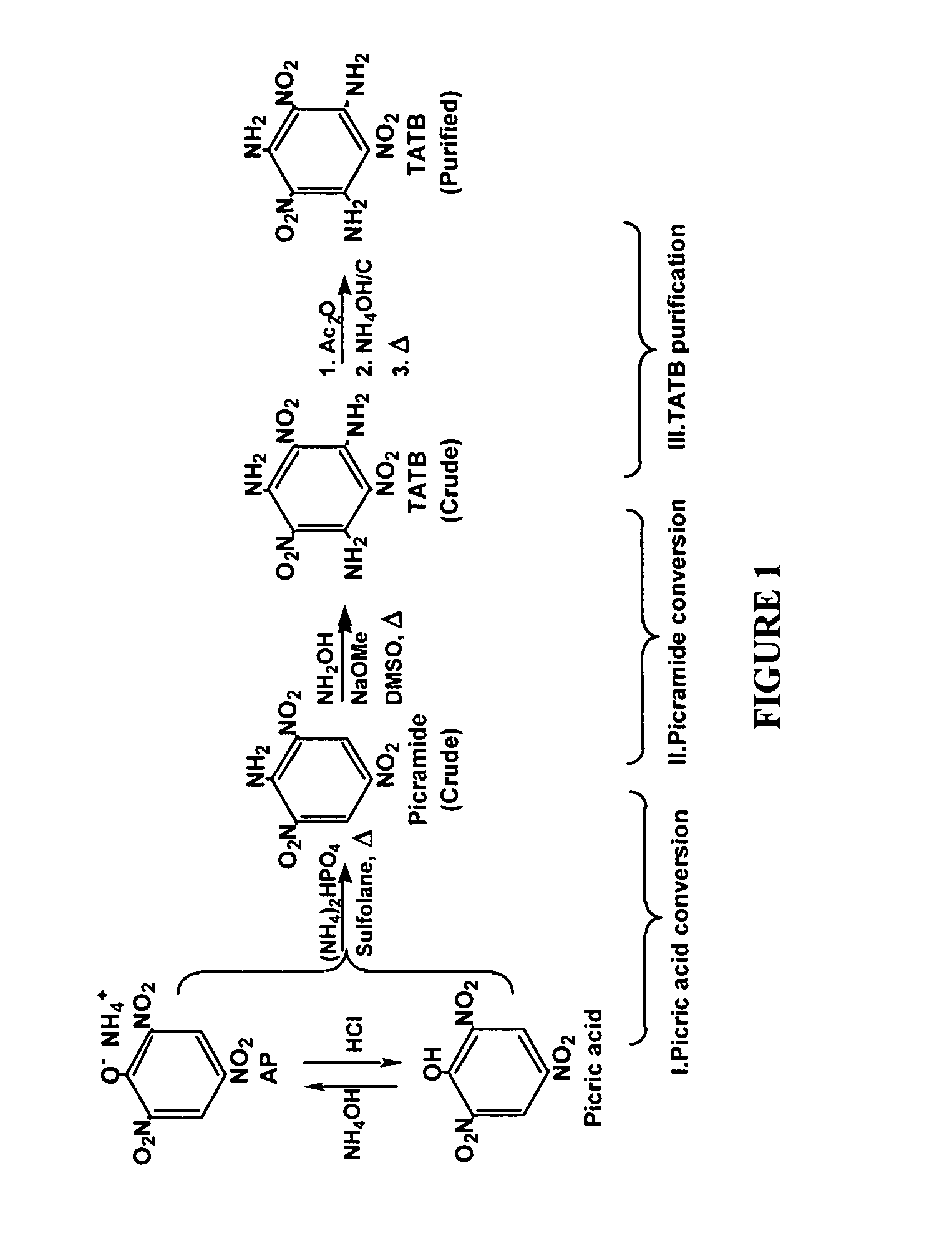

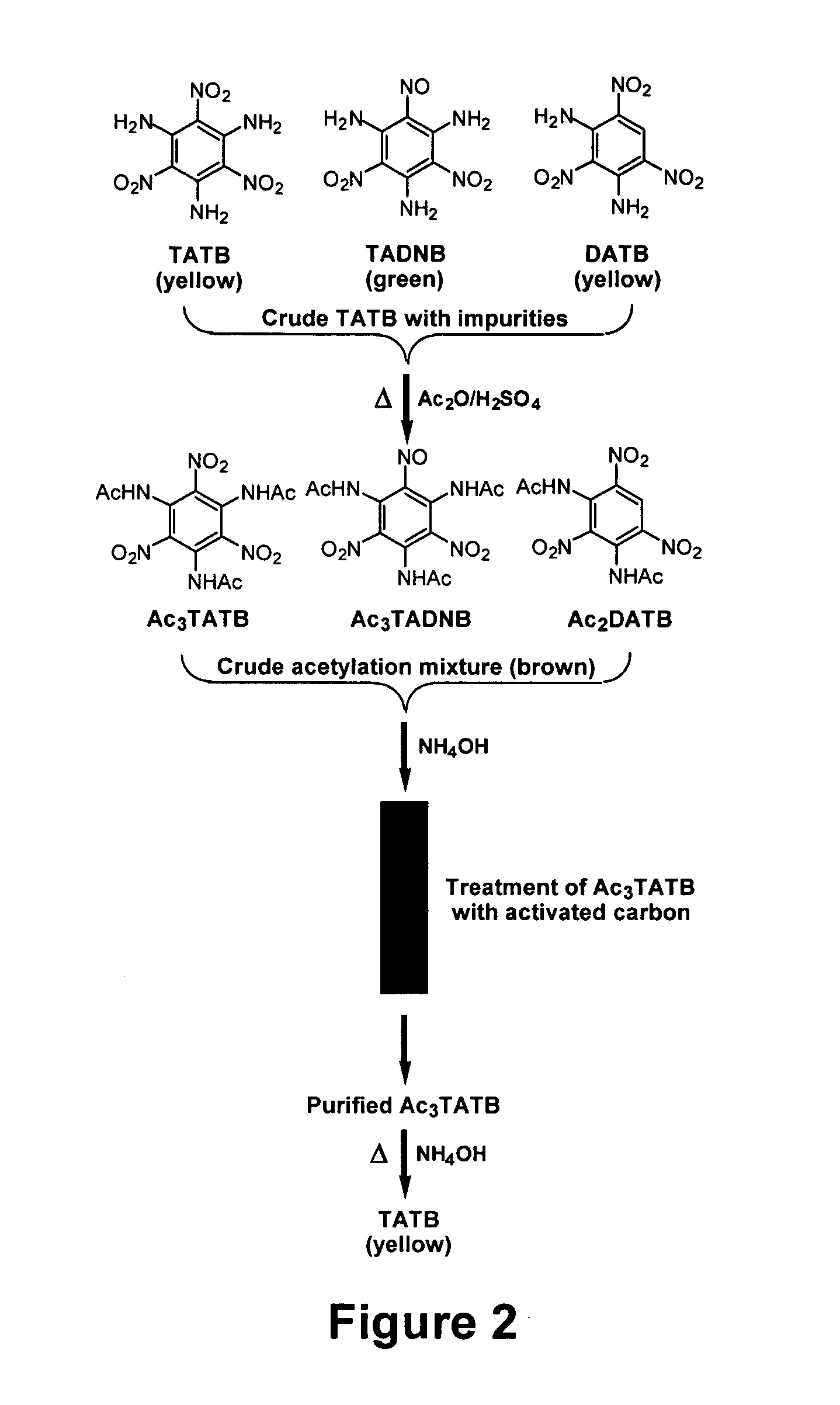

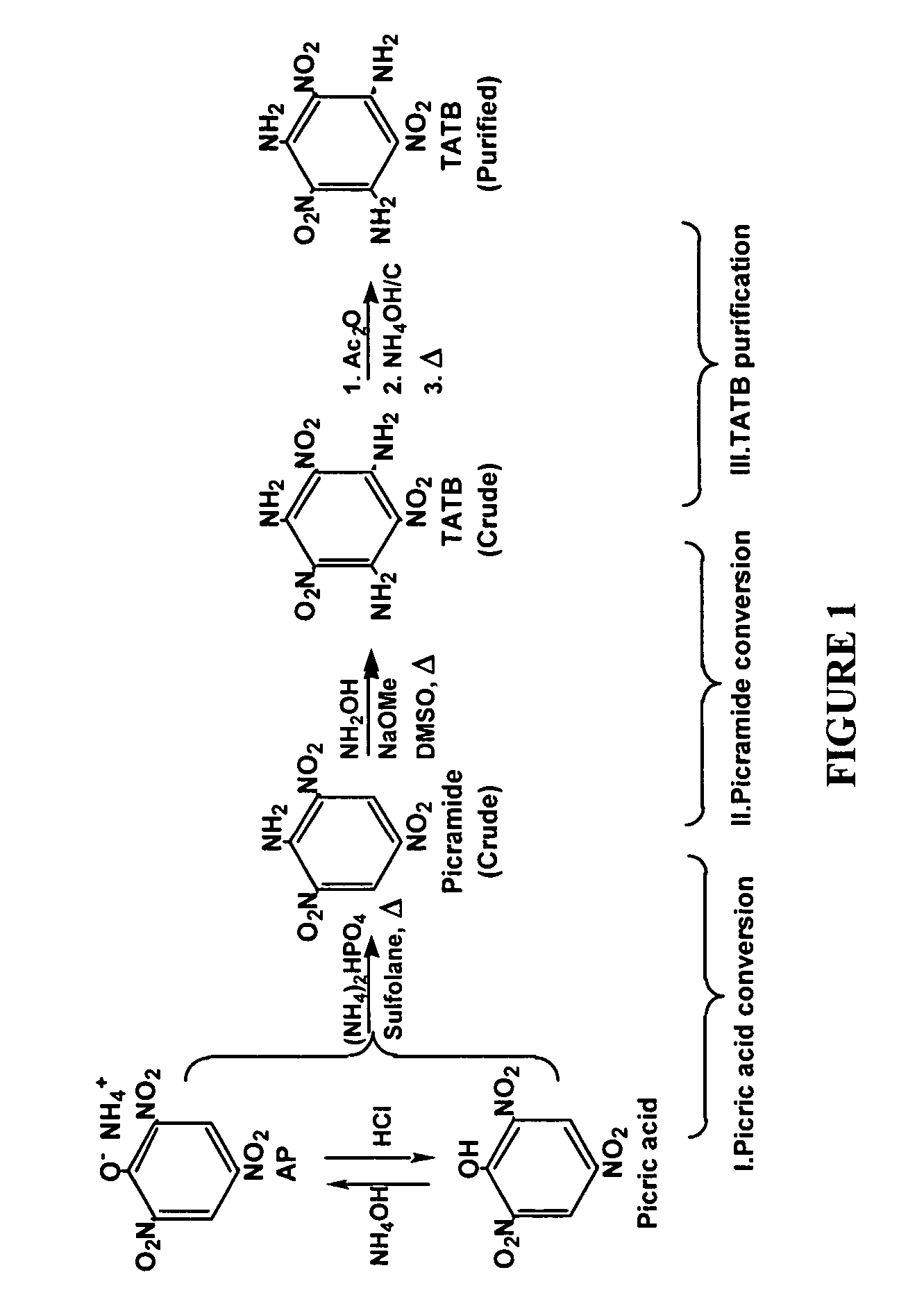

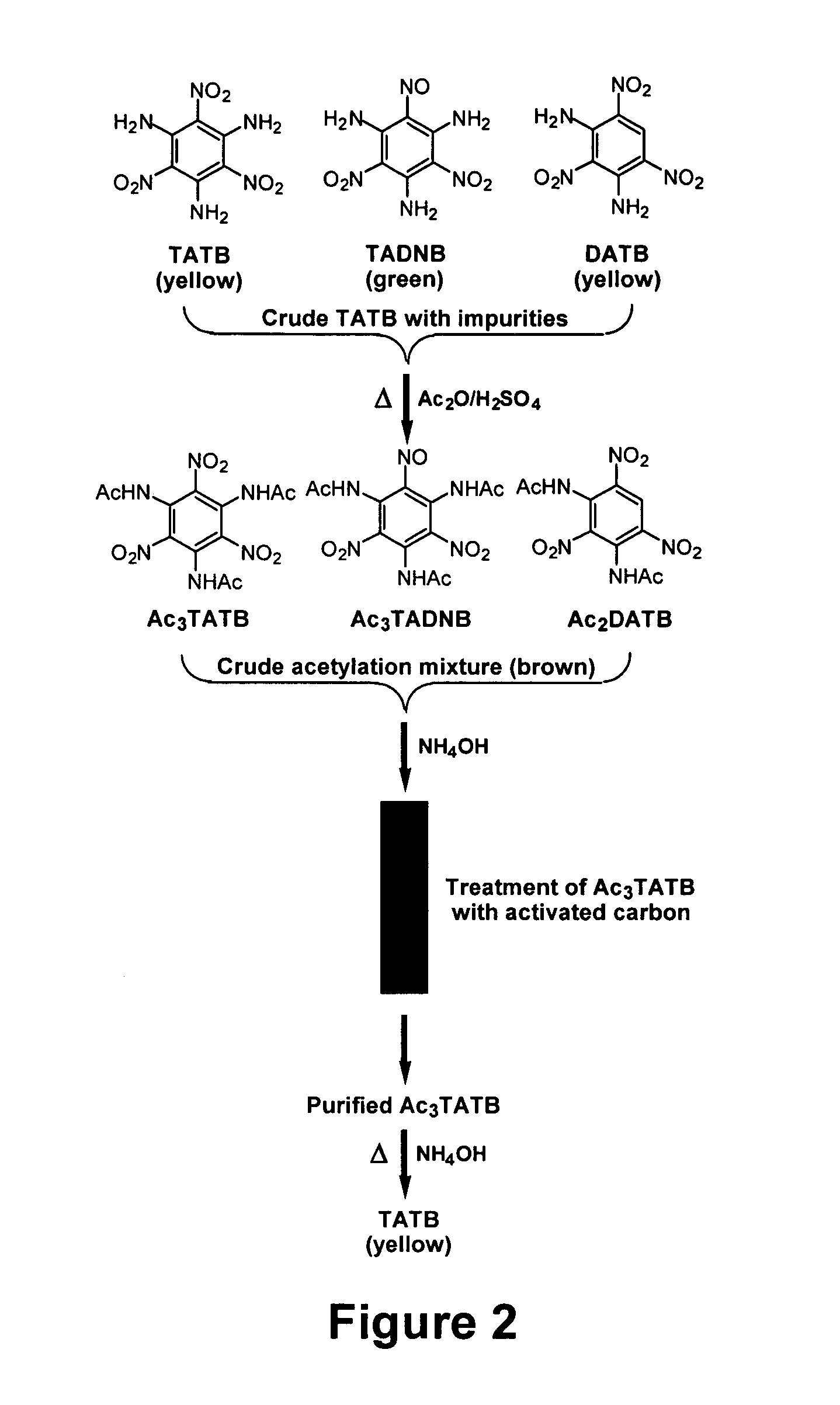

Synthesis and purification of 1,3,5-triamino-2,4,6-trinitrobenzene (TATB)

A method to convert surplus nitroarene explosives (picric acid, ammonium picrate,) into TATB is described. The process comprises three major steps: conversion of picric acid / ammonium picrate into picramide; conversion of picramide to TATB through vicarious nucleophilic substitution (VNS) of hydrogen chemistry; and purification of TATB.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

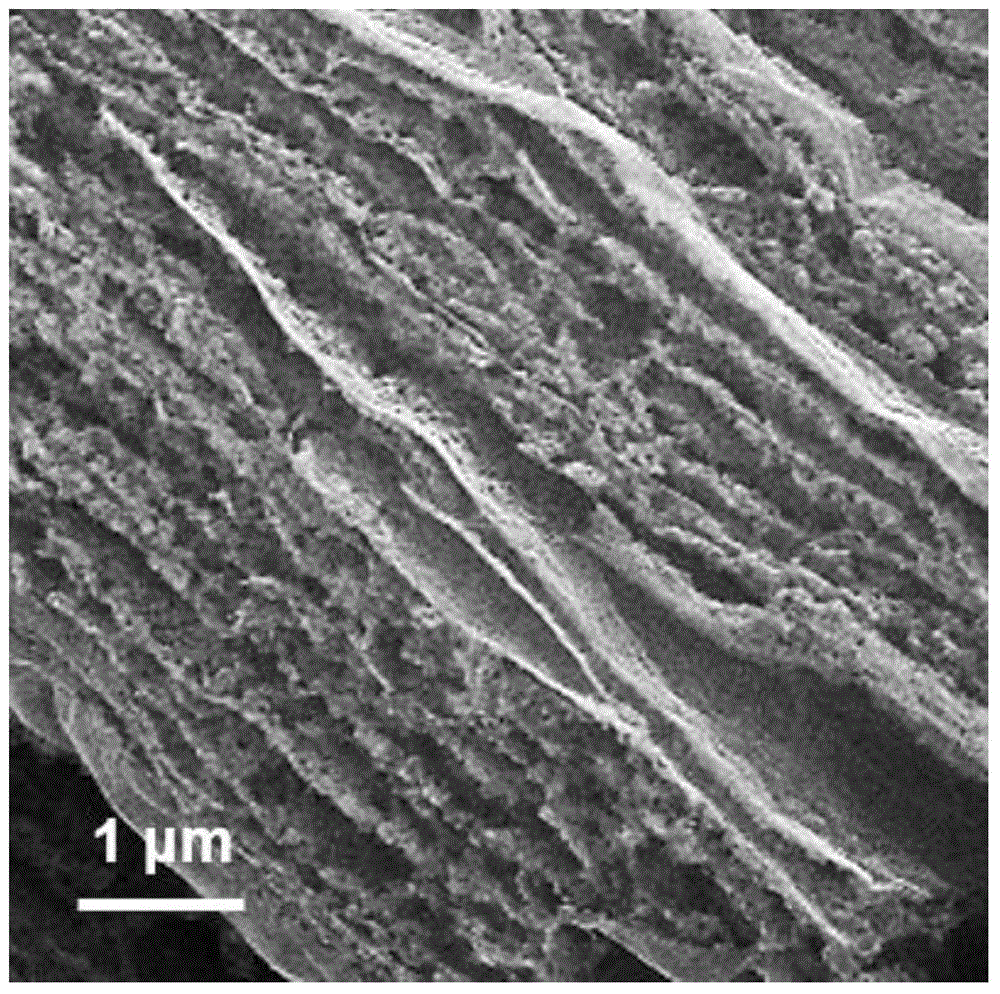

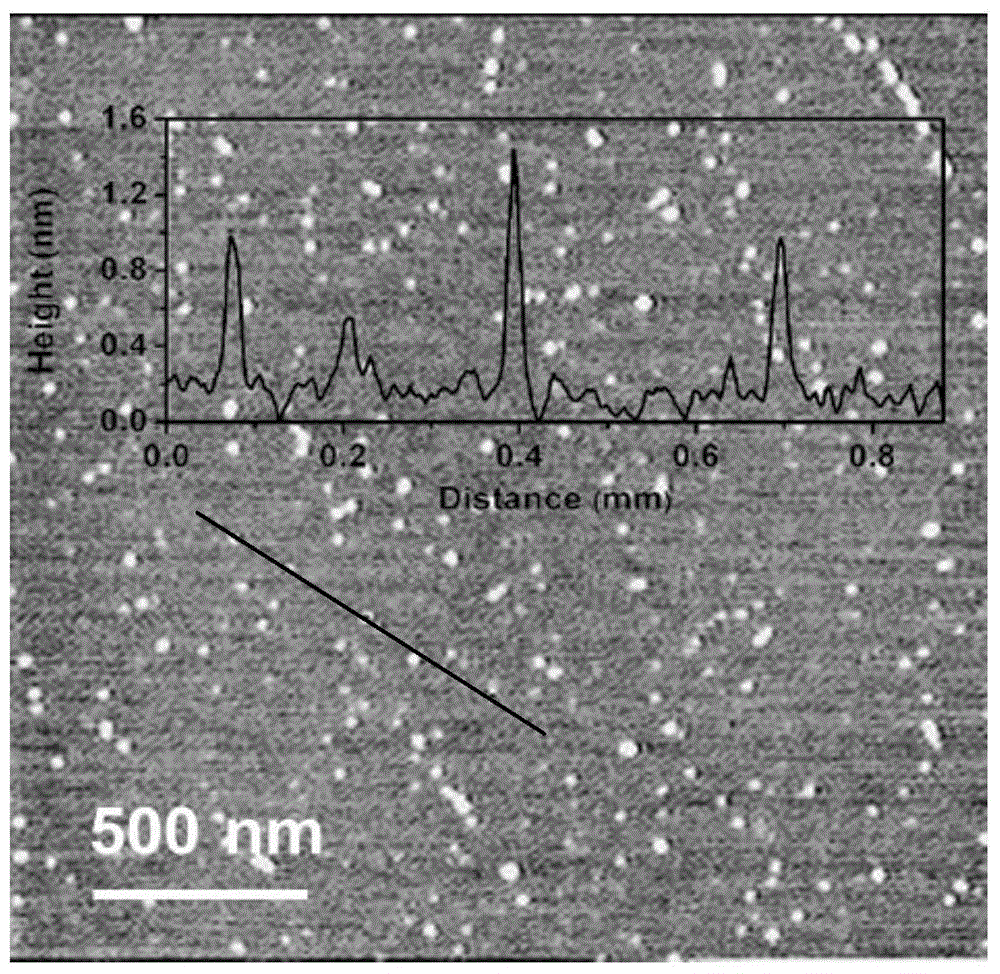

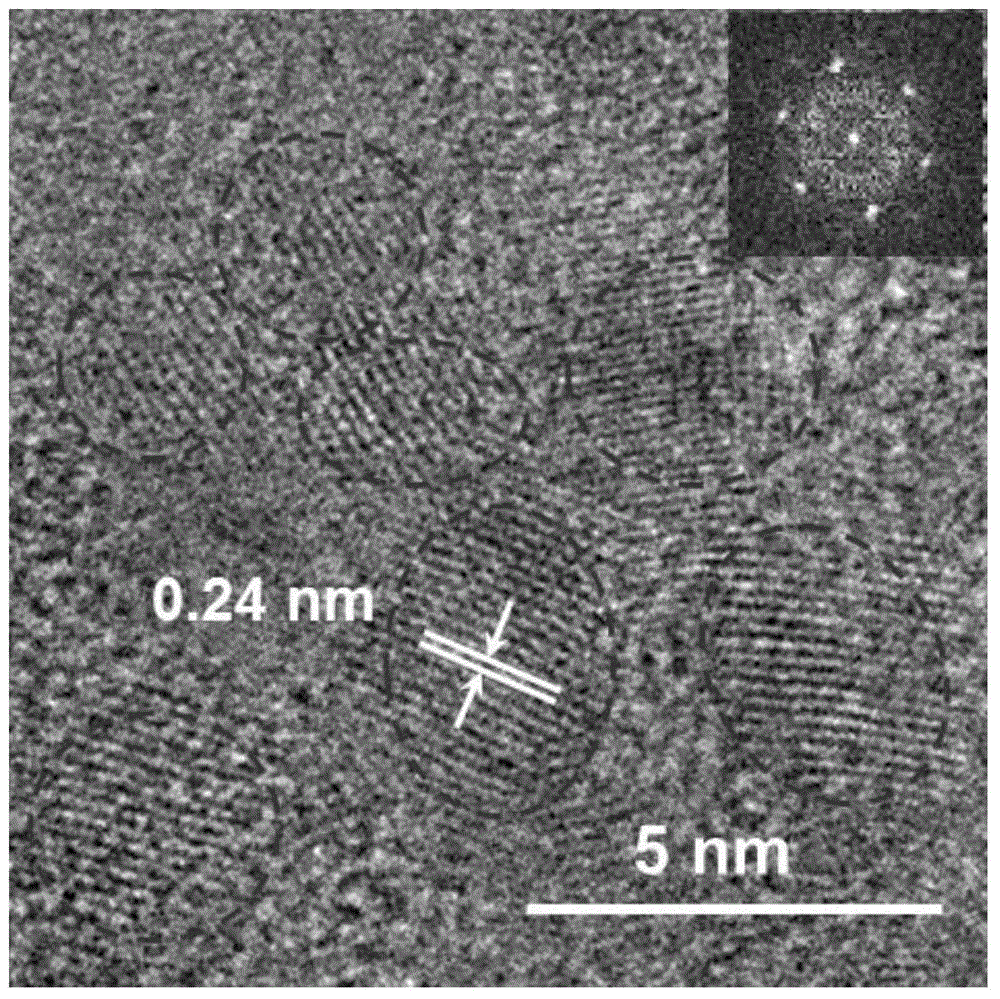

Preparation method and application of nitrogen-doped graphene quantum dots

ActiveCN104861967ALow priceWide variety of sourcesFluorescence/phosphorescenceLuminescent compositionsFluorescenceBiocompatibility Testing

The invention discloses a preparation method and an application of nitrogen-doped graphene quantum dots. According to the method, TATB (triamino trinitrobenzene) with a high nitrogen content is adopted as a raw material; pyrolysis is carried out; and the nitrogen-doped graphene quantum dots (N-GQDs) are prepared. The size of the nitrogen-doped graphene quantum dots is 2-10nm, the thickness of the nitrogen-doped graphene quantum dots is 0.5-1.5nm, and the nitrogen content of the nitrogen-doped graphene quantum dots is 4-30%. The nitrogen-doped graphene quantum dots can stably exist in a water solution for a long time. As a result of cell imaging studies, the nitrogen-doped graphene quantum dots can emit bright green fluorescence, has good biocompatibility, and almost has no toxicity against biological cells. The preparation method is simple; raw material cost is low; the requirement on equipment is low; and the prepared nitrogen-doped graphene quantum dots have excellent light-emitting performance.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

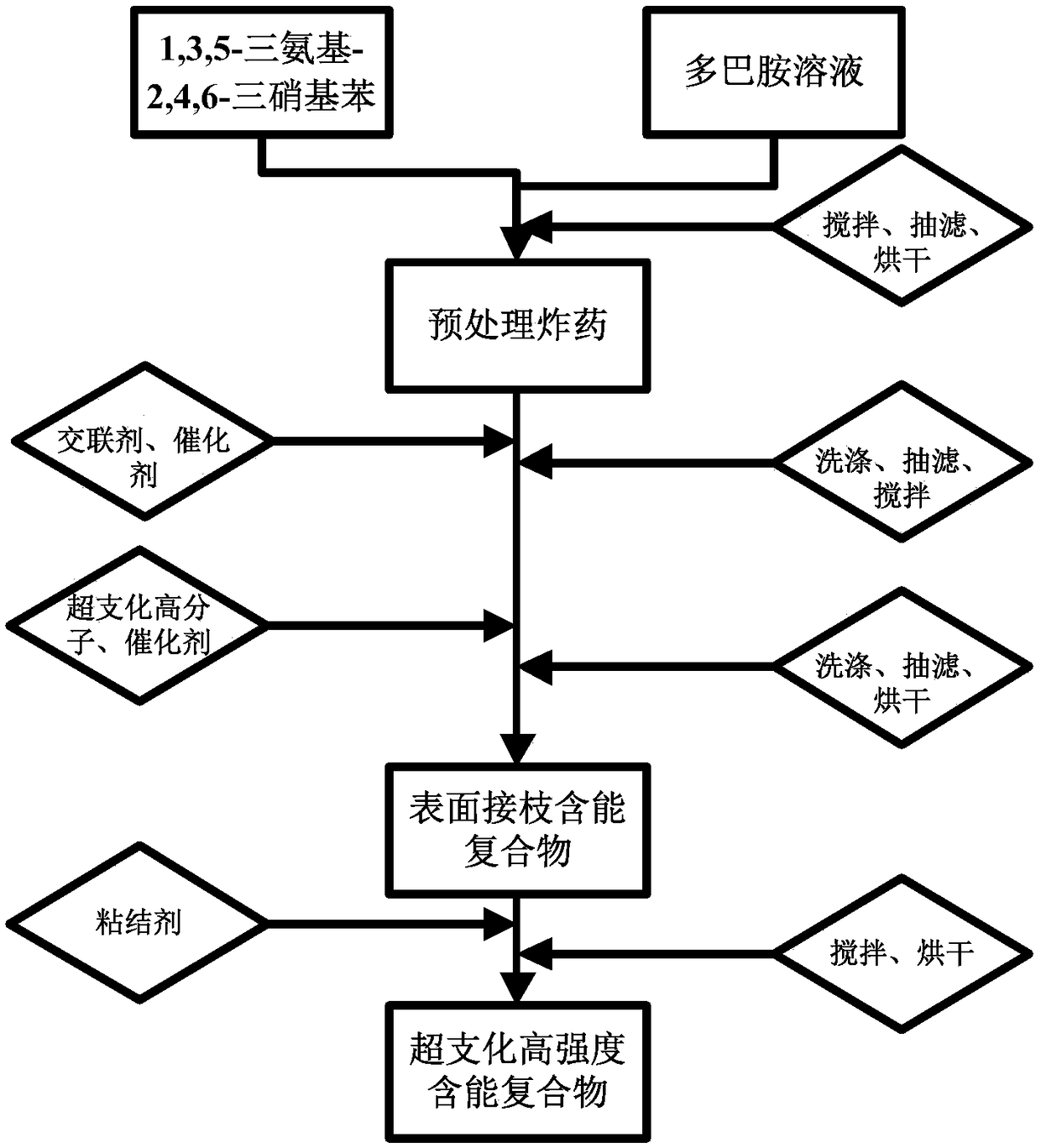

Hyperbranched high-strength energetic compound

ActiveCN109369315AImprove interface compatibilityImprove the technical problem of weak mechanical strengthNitrated aromatic explosive compositionsExplosive working-up apparatusPolymer scienceHyperbranched polyester

The invention discloses a hyperbranched high-strength energetic compound which is composed of an energetic crystal 1,3,5-triamido-2,4,6-trinitrobenzene, a hyperbranched polymer and a polymer binder. The invention further provides a preparation method of the hyperbranched high-strength energetic compound. The explosive crystal / hyperbranched polyester energetic compound disclosed by the invention has the compressive fracture strength of more than 34MPa and the Brazilian split strength of more than 8MPa, is an energetic compound with high mechanical strength, and has important application prospects for improving the comprehensive environmental adaptability of the charge.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

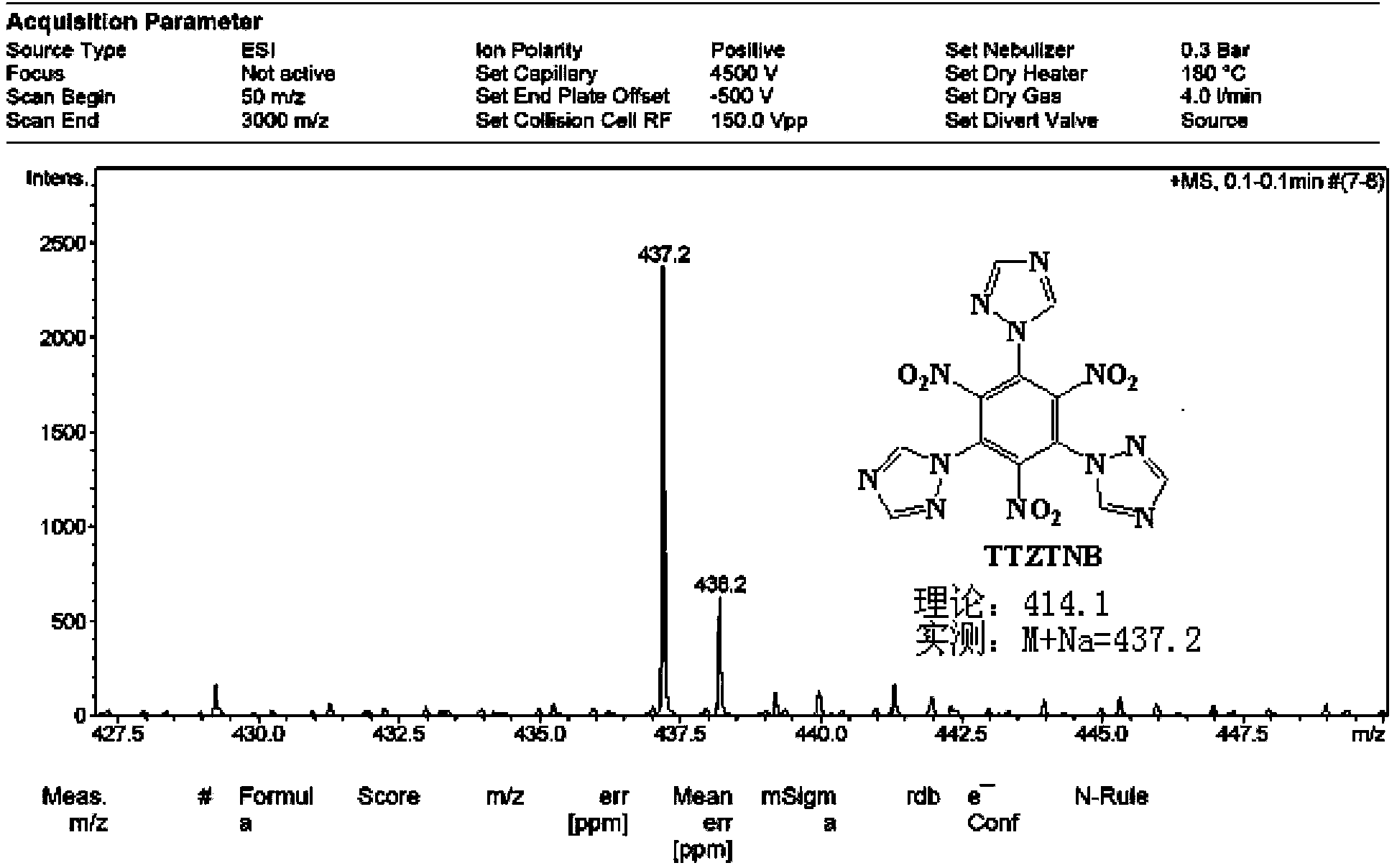

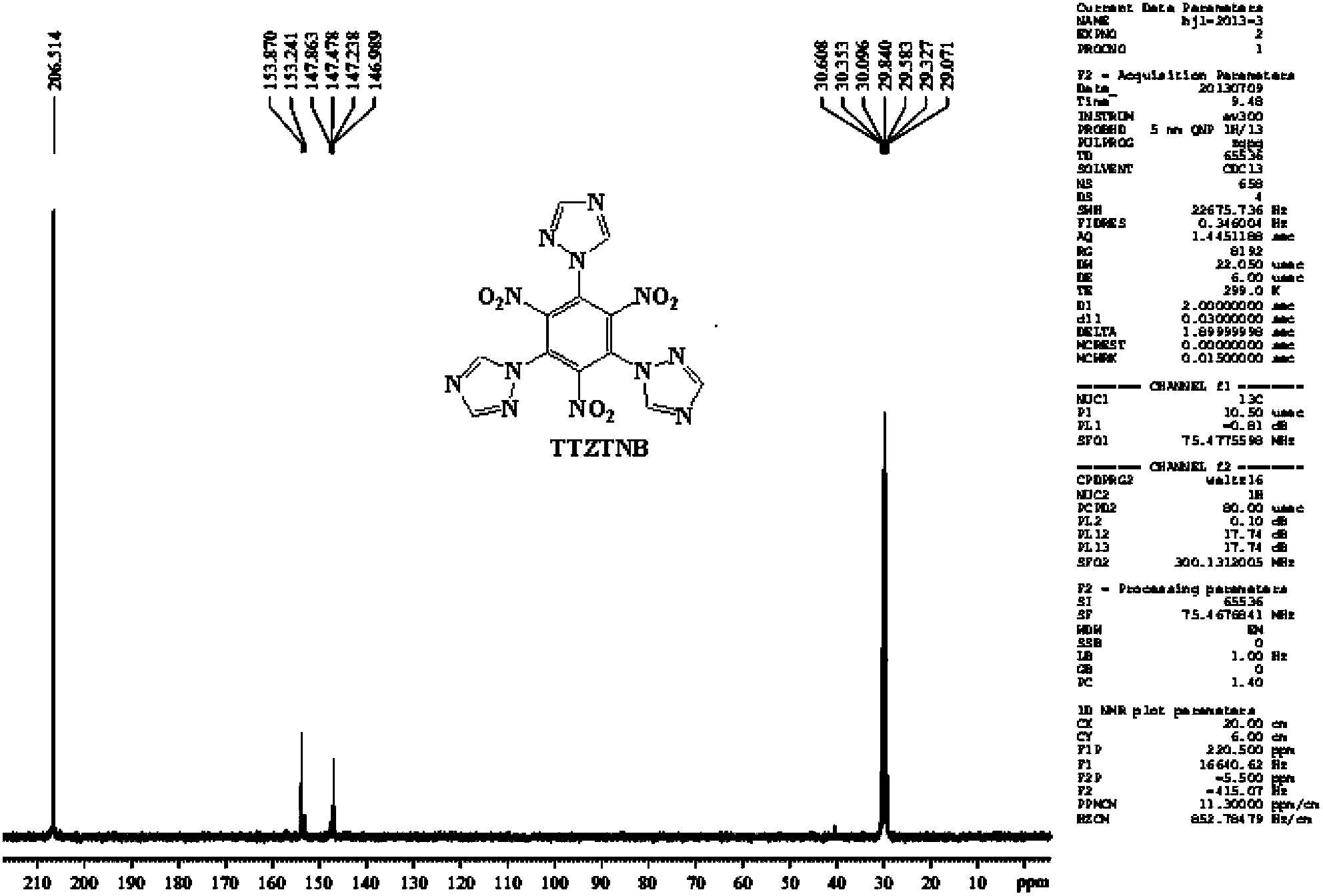

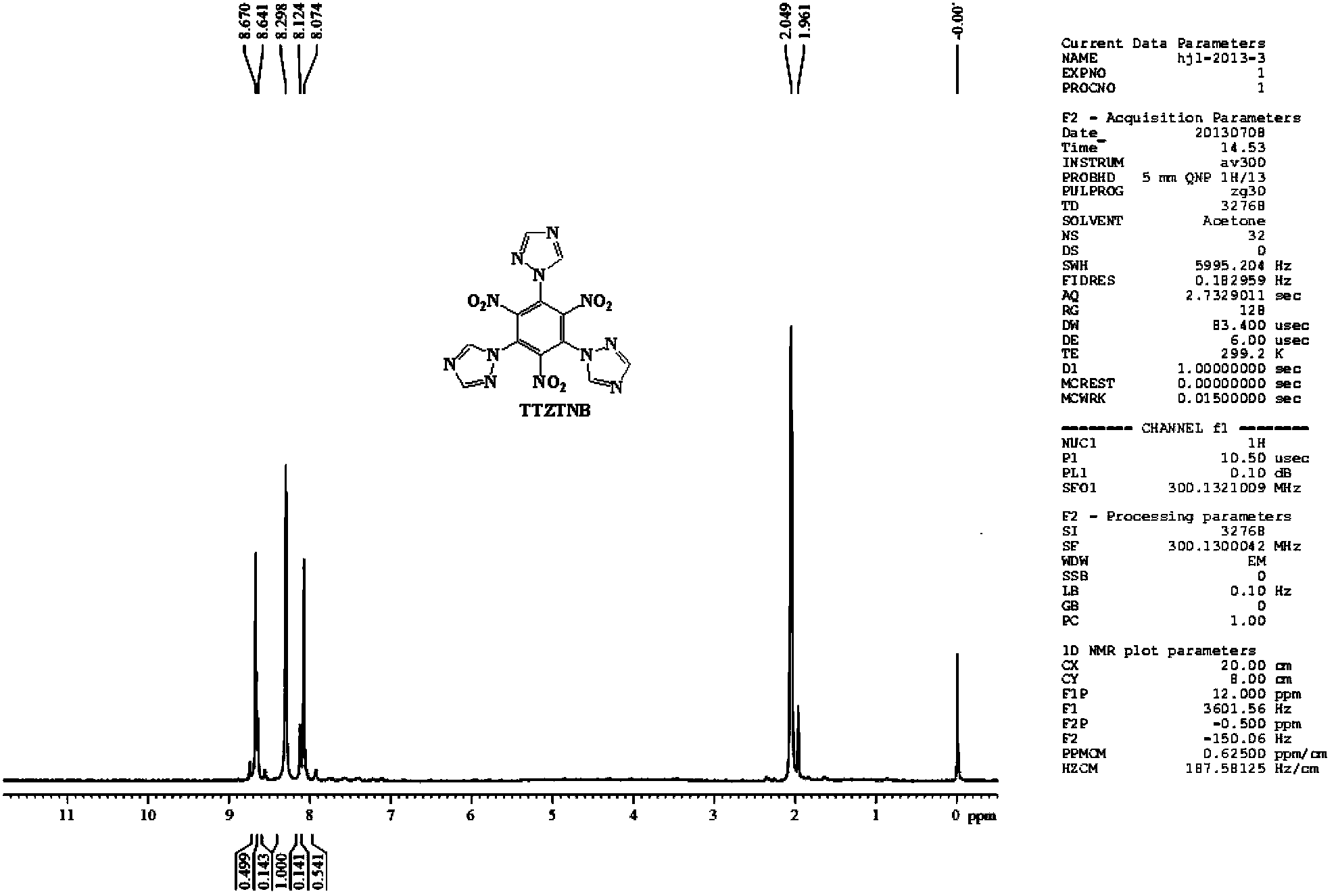

Energetic compound 1,3,5-three(1H-1,2,4-triazolyl)-2,4,6-trinitrobenzene and synthetic method thereof

ActiveCN103396374AHigh energy lowIncrease energy densityOrganic chemistryRotary evaporatorVacuum drying

The invention discloses an energetic compound 1,3,5-three(1H-1,2,4-triazolyl)-2,4,6-trinitrobenzene and a synthetic method thereof. The synthetic method comprises the following steps: dissolving 1,3,5-trichloro-2,4,6-trinitrobenzene in a reaction medium, adding 1H-1,2,4-triazole, then adding a catalyst at a constant temperature, carrying out a reaction until no material point is detected by thin-layer chromatography, filtering the solid-liquid mixture under reduced pressure, steaming off the reaction medium in the filtrate by a rotary evaporator, then separating and purifying by a column chromatography method, and carrying out vacuum drying to obtain the target product 1,3,5-three(1H-1,2,4-triazolyl)-2,4,6-trinitrobenzene. The new compound is the novel energetic material having good potential application prospects. The synthetic method adopts 1,3,5-trichloro-2,4,6-trinitrobenzene and 1H-1,2,4-triazole as the raw materials, synthesizes the target product through the coupling reaction, has mild reaction conditions in the synthetic steps and simple reaction steps, and is suitable for mass production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

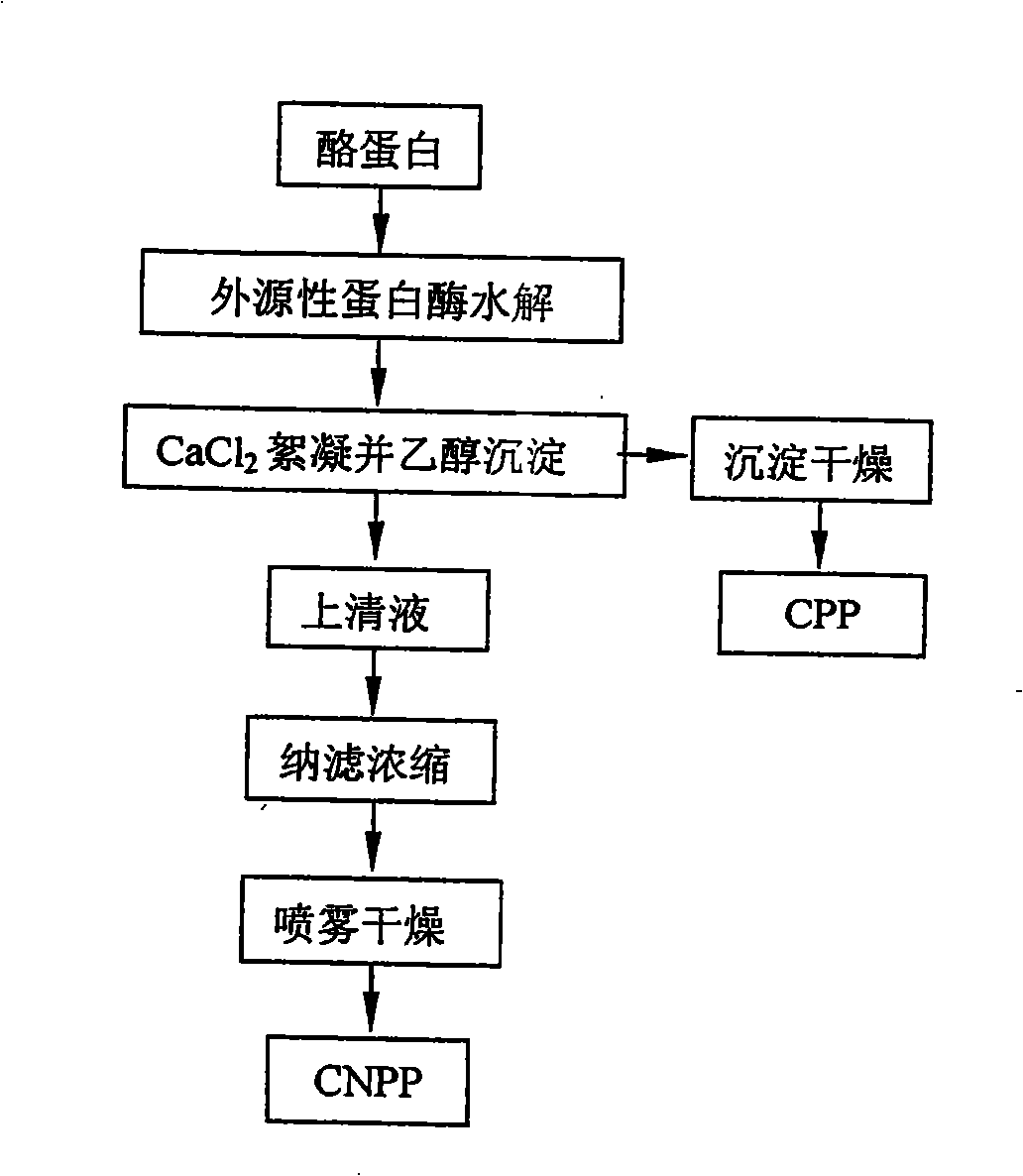

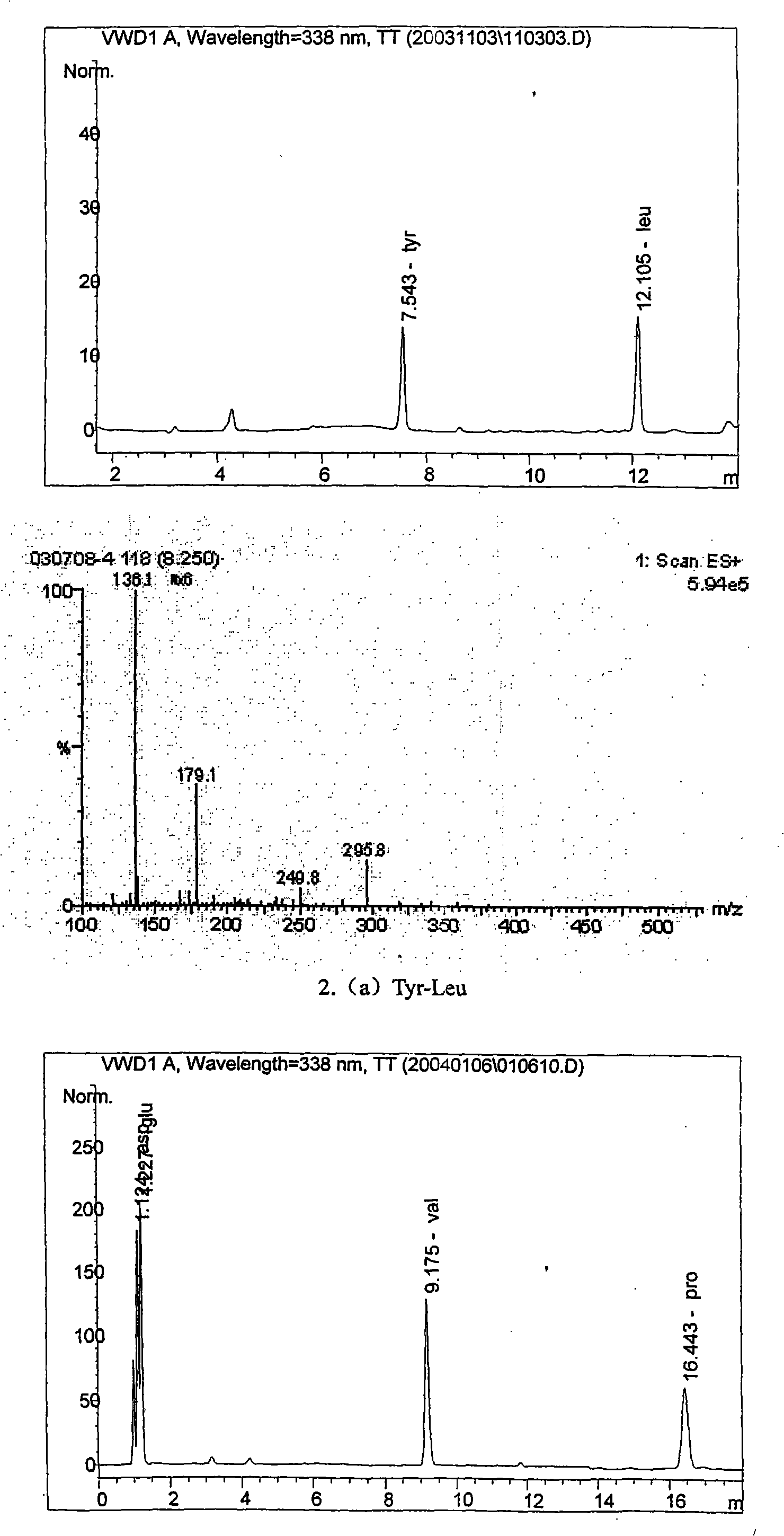

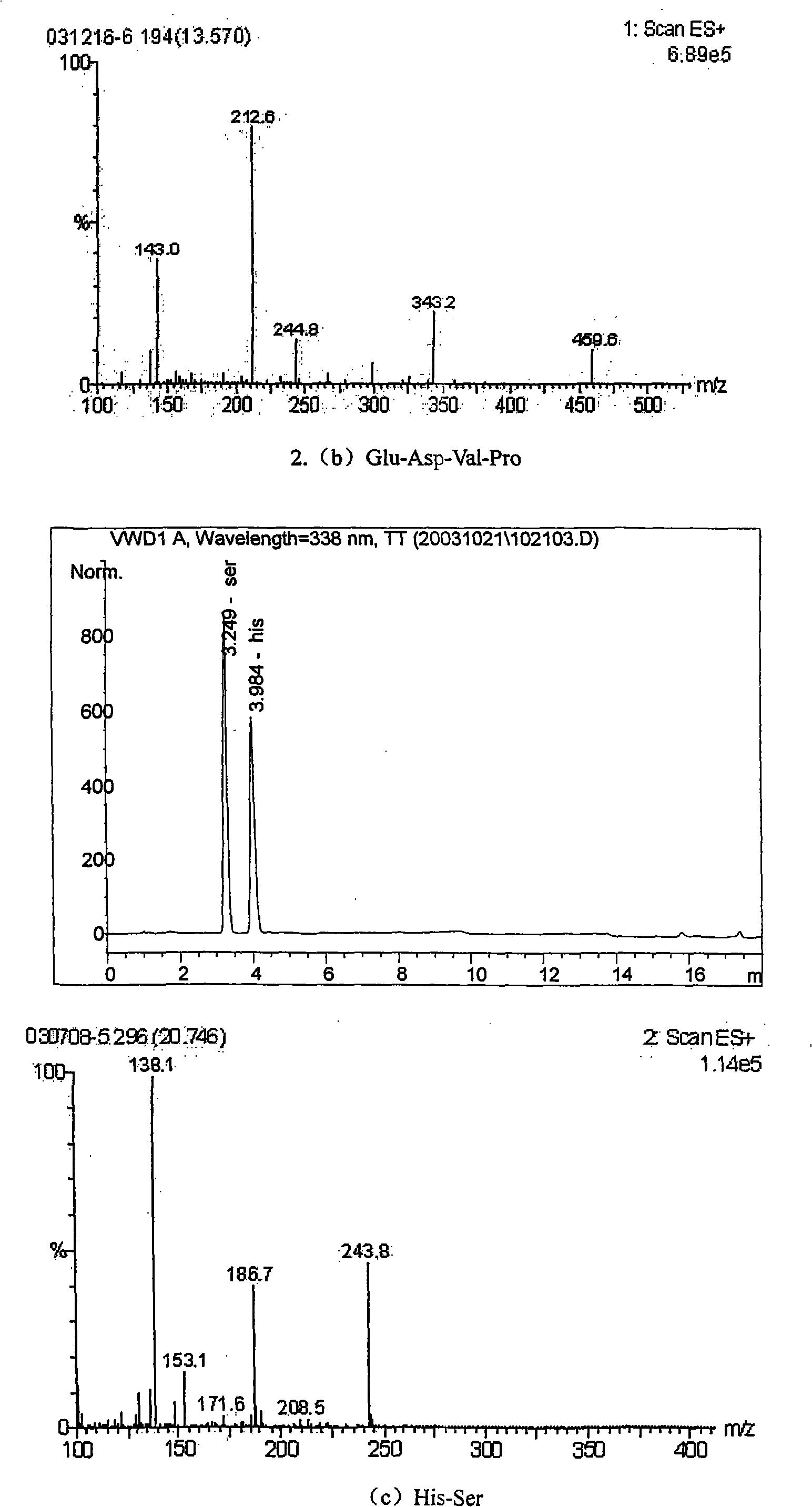

Process for preparing phosphopeptide non-phosphopeptide by hydrolyzing protein through enzyme

The invention discloses a method for preparing casein phosphopeptide and casein non-phosphopeptide through enzymatic hydrolysis casein. The method mainly uses the casein as raw material, uses single alkali protease Alcalase2.4L to control the hydrolysis, uses a trinitrobenzene sulfonic acid method to monitor a DH value, and uses an alcohol-calcium isolation method to simultaneously prepare CPP and CNPP from the casein hydrolyte. The mol ratio of nitrogen to phosphor is 20-25 to 1 with a yield above 35 percent. The obtaining ratio of CNPP reaches 45 percent. The amino acid sequences of two ACE inhibition bioactive peptides and an oxidation resistant bioactive peptides in the CNNP product are identified as follows: Tyr-Leu, Glu-Asp-Val-Pro and His-Ser. The method provided by the invention has a good enzyme hydrolysis effect, a proper price, a reasonable process route, a high material utilization rate and easy amplification. The products of CPP and CNPP can be widely applicable to functional food ingredient and health food.

Owner:J JIANGSU LIANGFENG FOODSTUFF GROUP

Synthesis and purification of 1,3,5-triamino-2,4,6-trinitrobenzene (TATB)

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

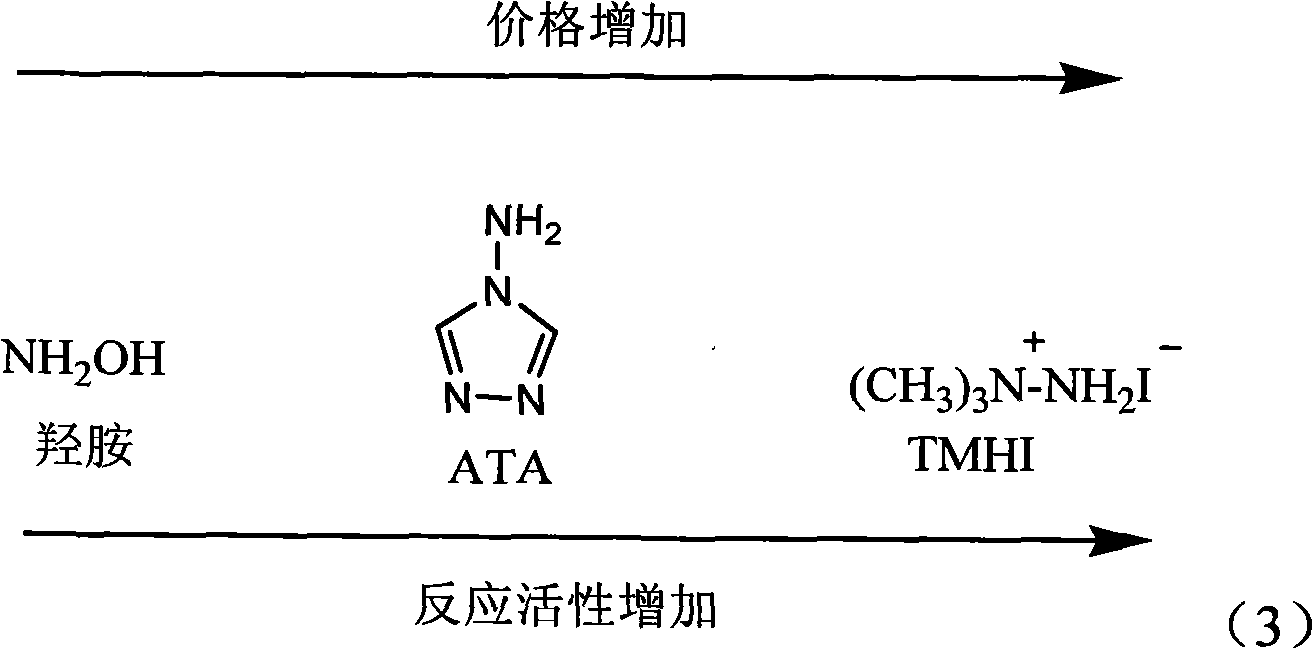

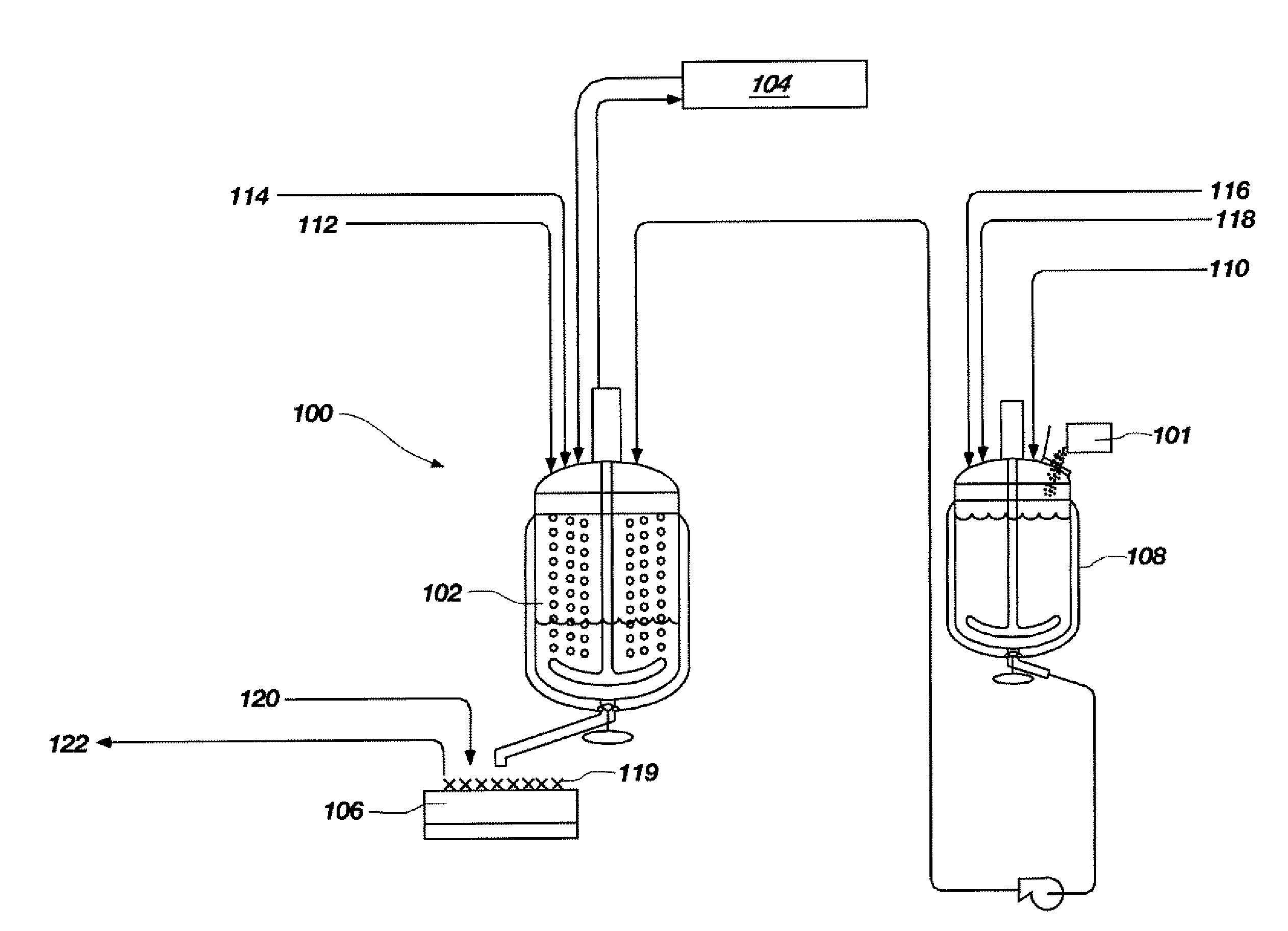

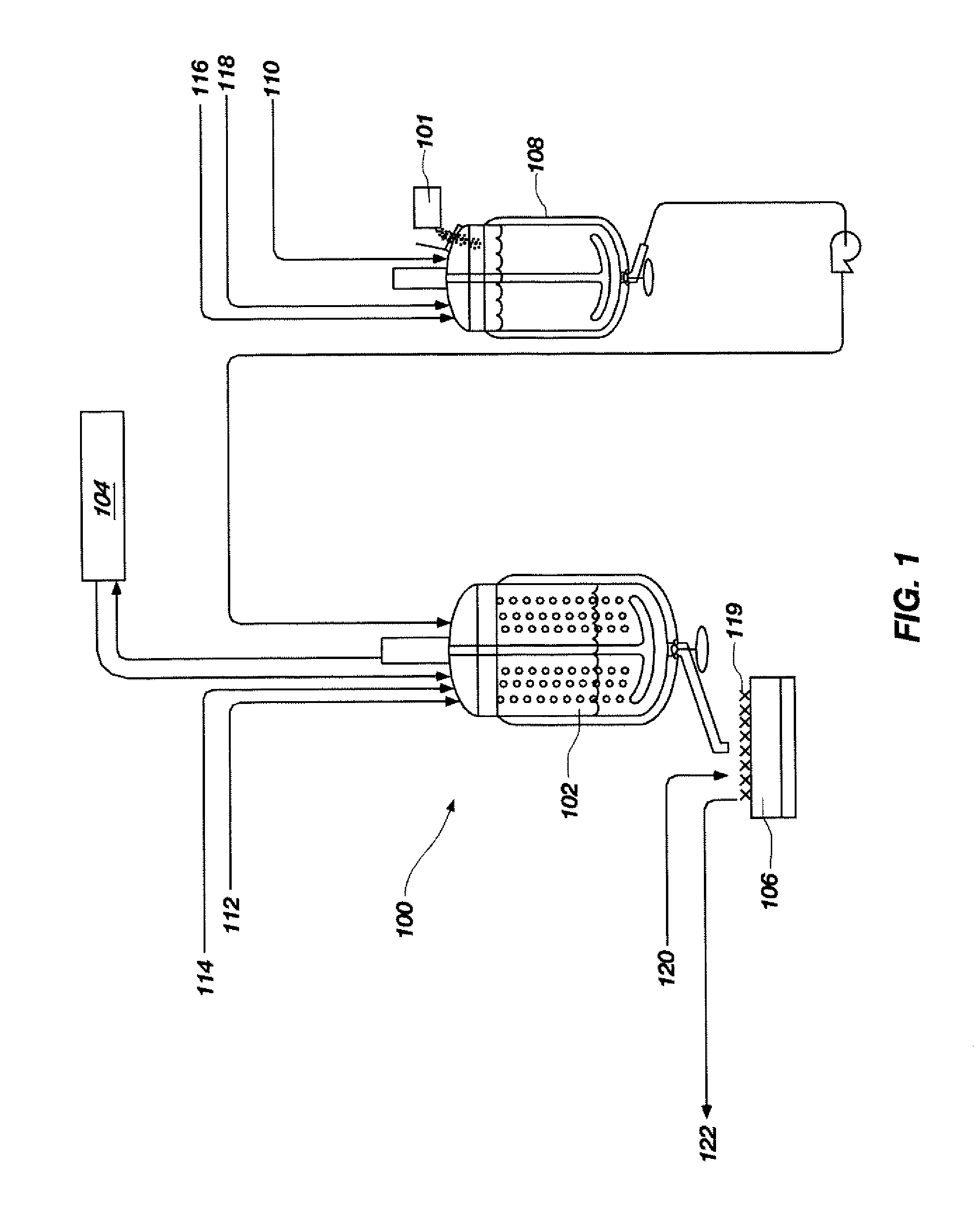

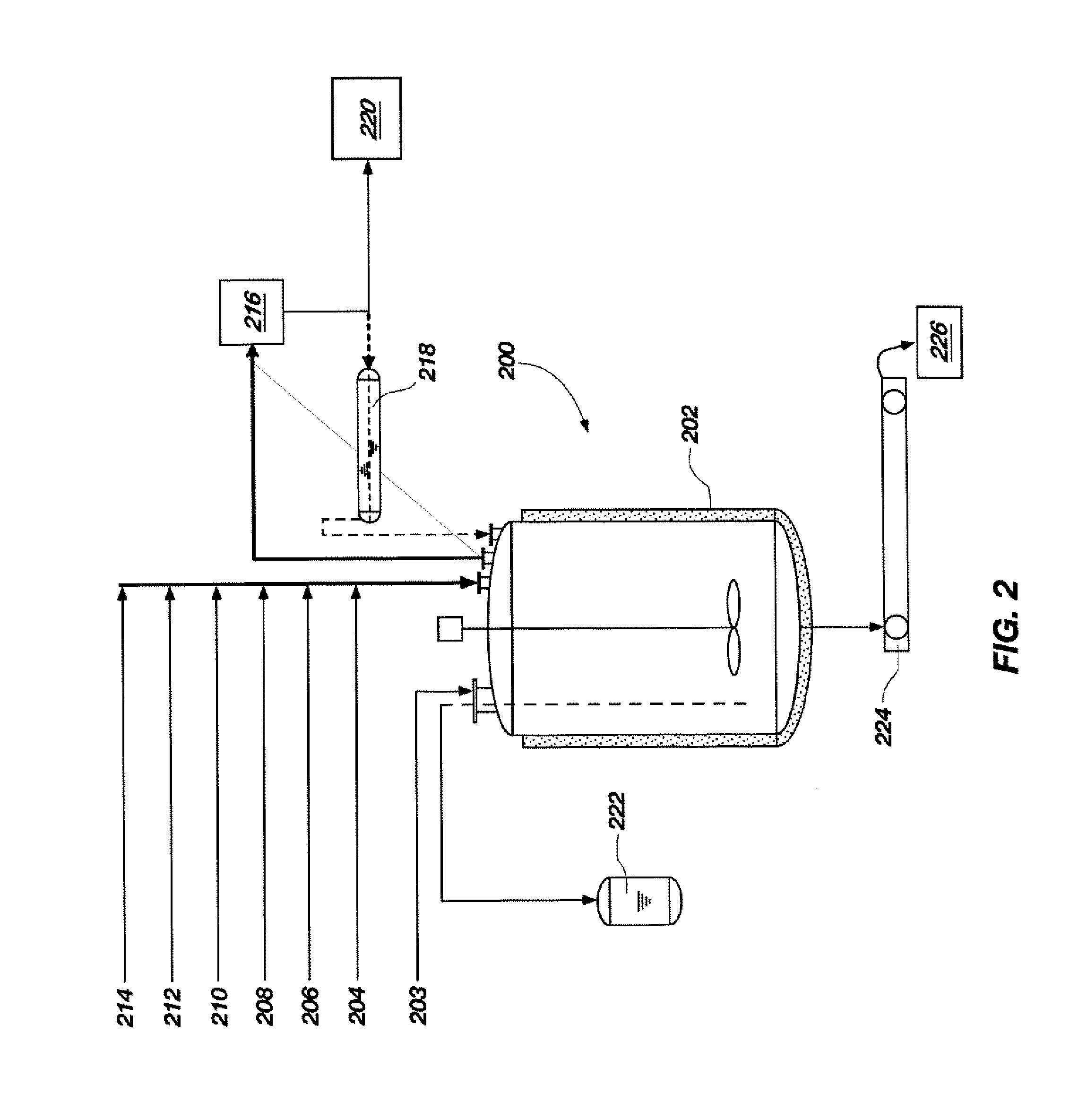

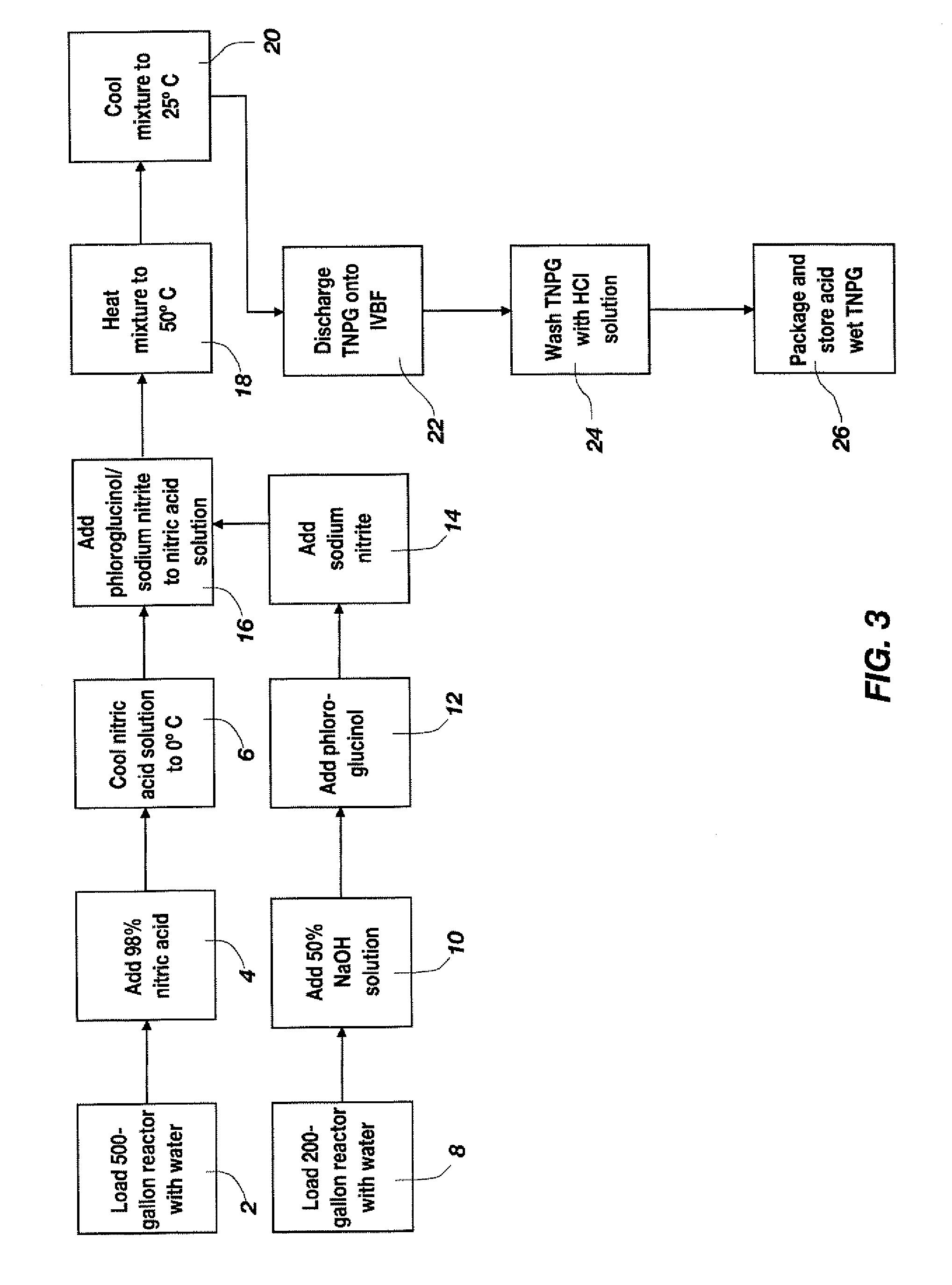

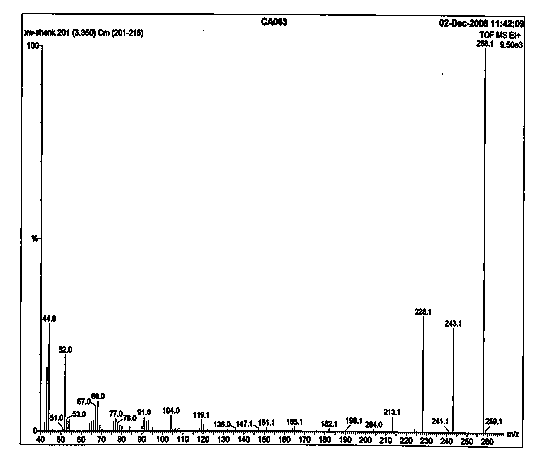

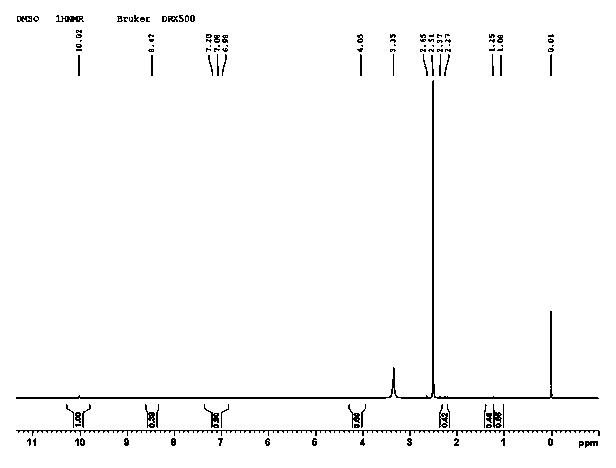

Methods of producing 1,3,5-triamino-2,4,6-trinitrobenzene

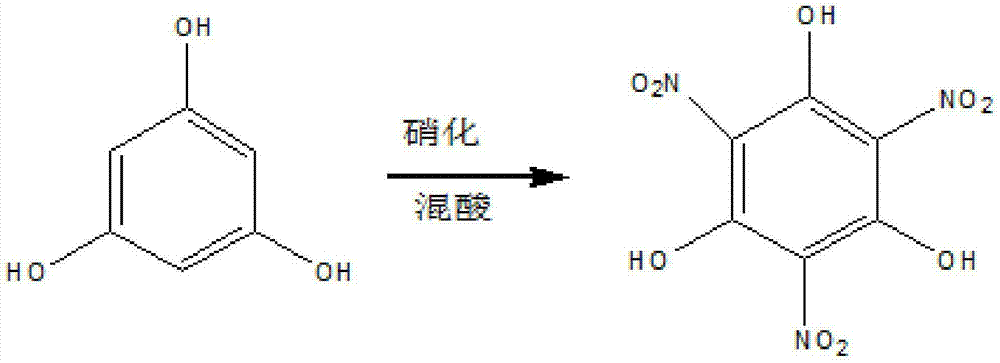

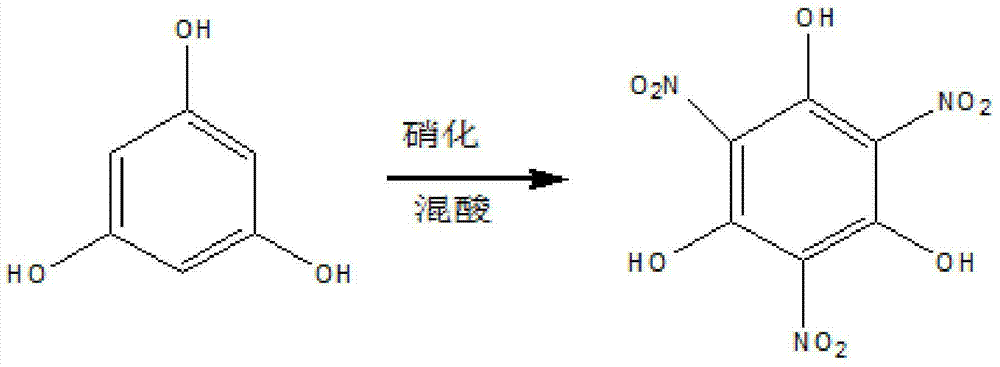

InactiveUS20110172463A1Sure easyOrganic compound preparationAmino preparation by functional substitutionTATBPhloroglucinol

Methods of producing TATB are disclosed. The method comprises providing acid wet TNPG and distilling water from the acid wet TNPG. The TNPG is reacted with an alkoxylating agent to form a solution of 1,3,5-trialkoxy-2,4,6-trinitrobenzene solution, which is reacted with an aminating agent. An alternate method comprises nitrating phloroglucinol in a first vessel to produce TNPG, which is reacted with an alkoxylating agent in a second vessel to form a solution comprising 1,3,5-trialkoxy-2,4,6-trinitrobenzene and at least one of at least one volatile byproduct and at least one nonvolatile byproduct. The at least one of at least one volatile byproduct and at least one nonvolatile byproduct is removed in situ. The 1,3,5-trialkoxy-2,4,6-trinitrobenzene is reacted with an aminating agent.

Owner:NORTHROP GRUMMAN SYST CORP

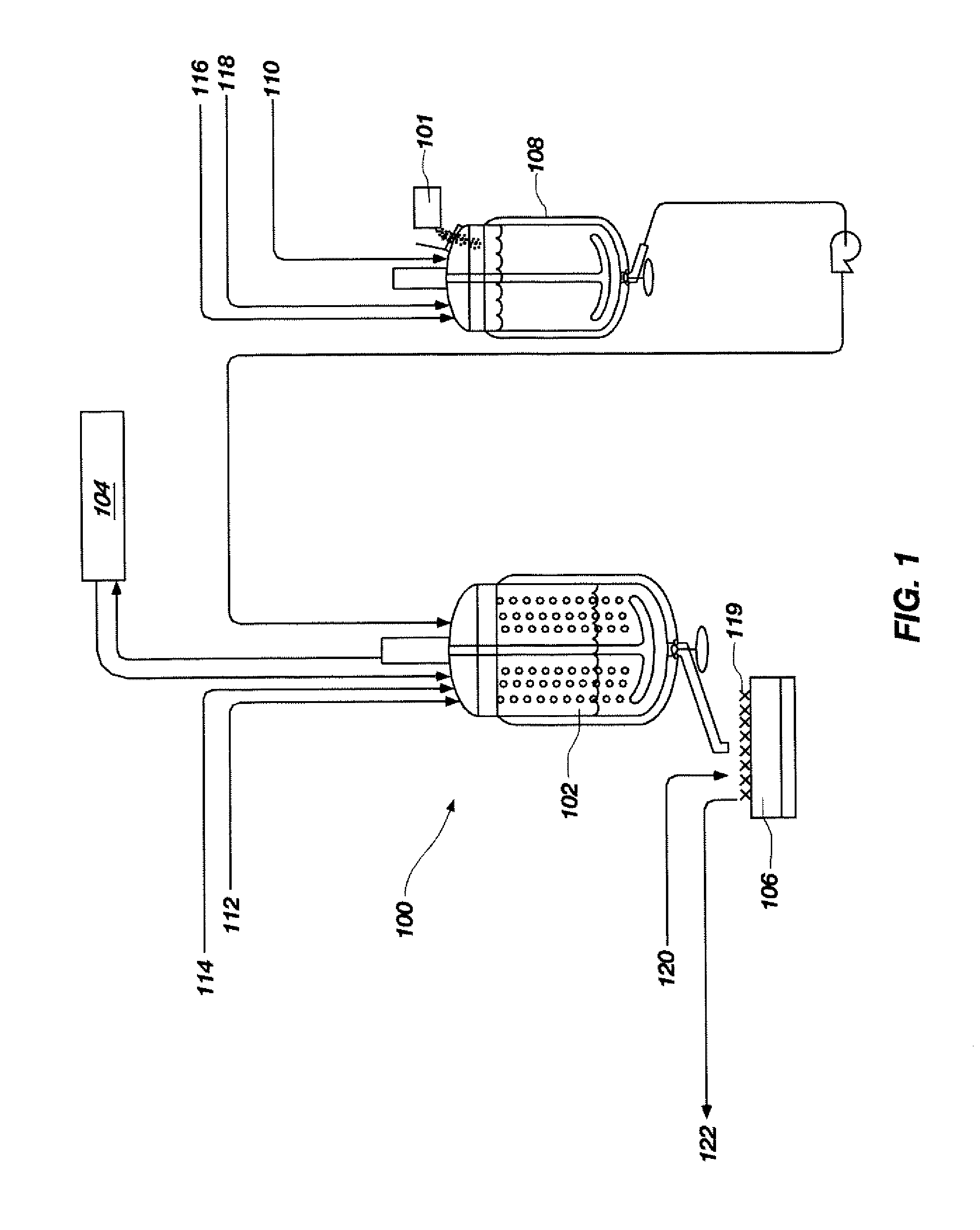

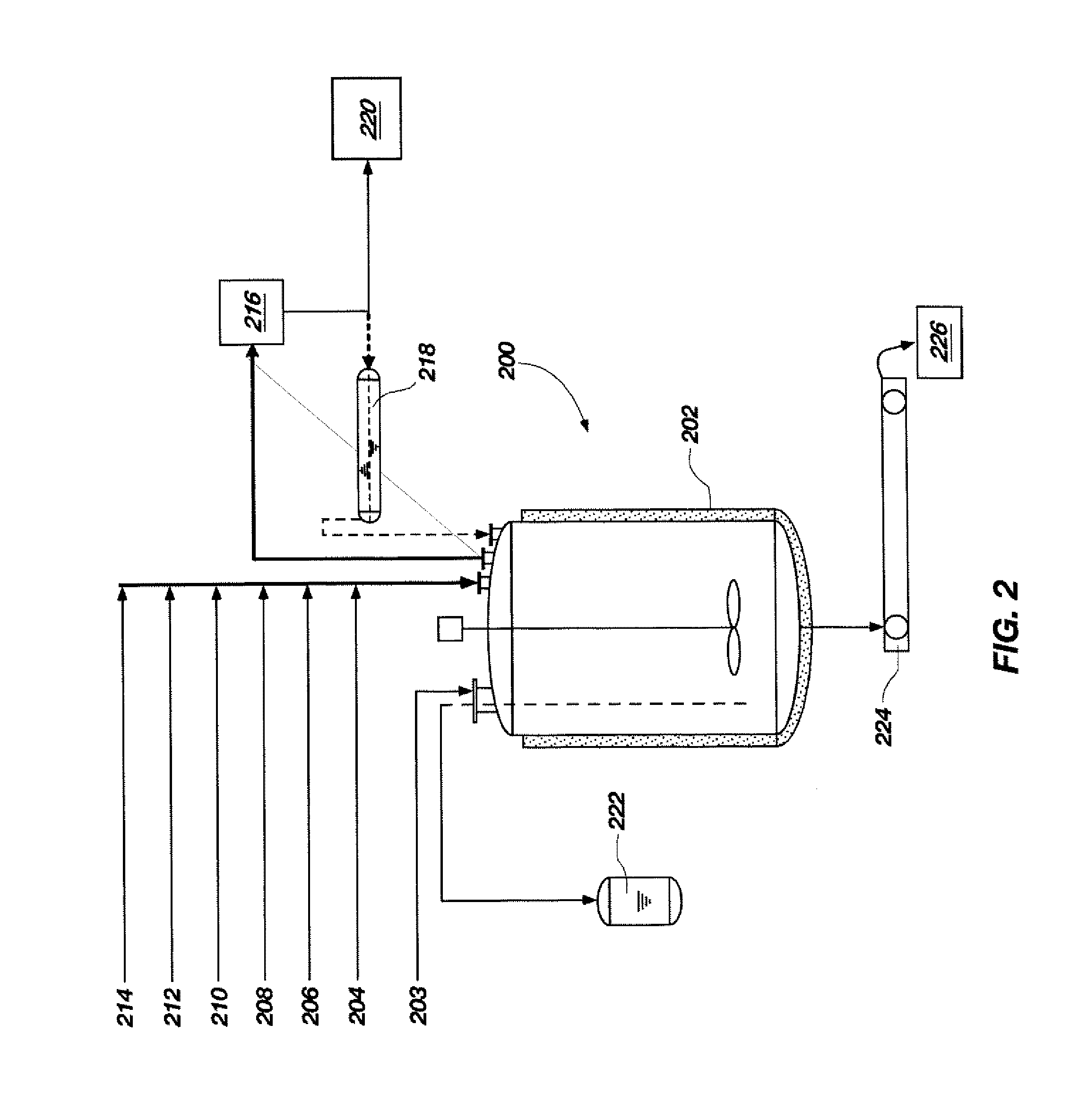

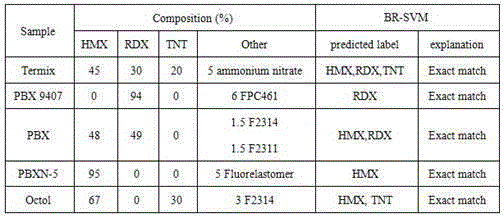

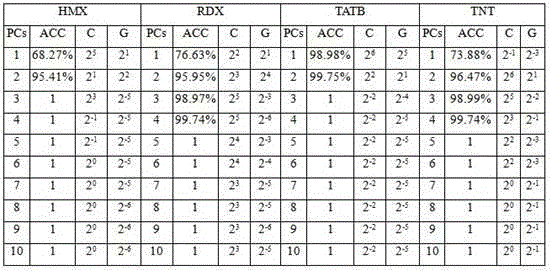

New method for quantitatively recognizing mixed explosive components by combining infrared spectroscopy and chemometrics

InactiveCN105300918AImprove robustnessImprove stabilityMaterial analysis by optical meansNear-infrared spectroscopySupport vector machine

The invention discloses a new multi-label algorithm analysis method combining infrared spectroscopy and chemometrics. Four components of (octogen (HMX), hexogen(RDX), triamino trinitrobenzene (TATB) and trinitrotoluene (TNT)) in plastic bonded explosives (PBX) can be fast and quantitatively recognized at the same time, and measurable samples comprise single-component, double-component and three-component PBX. The method includes the following main steps that PBX samples in different concentrations are prepared, wherein 118 training sets exist, 28 independent testing sets exist, four kinds of explosives in the training sets are recognized through a support vector machine to be subjected to modeling and optimization, an optimal model is applied to the training sets and five true samples, and whether unknown mixed explosives contain HMX, RDX, TATB and TNT or not can be directly predicted. Compared with a traditional experimental method, no pre-separation needs to be performed on PBX, only the sample infrared spectrum needs to be measured, operation is easy, analysis speed is high, and accuracy is high.

Owner:SICHUAN UNIV

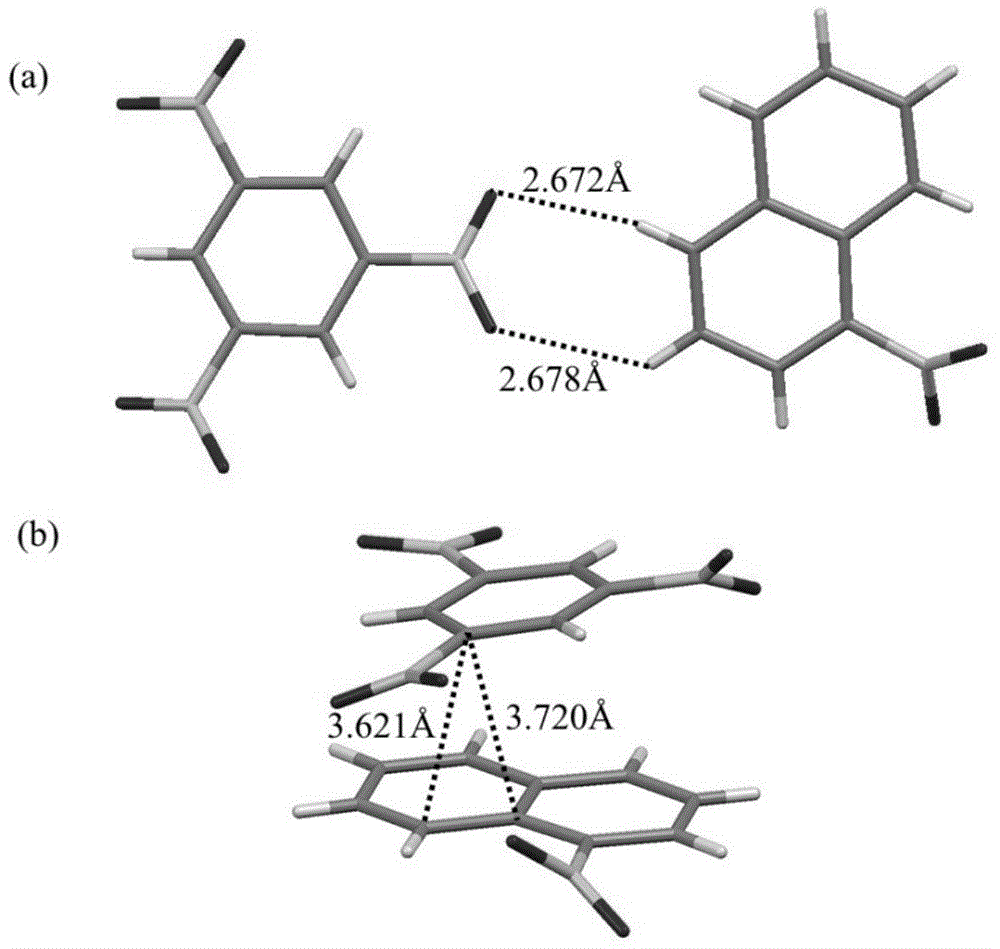

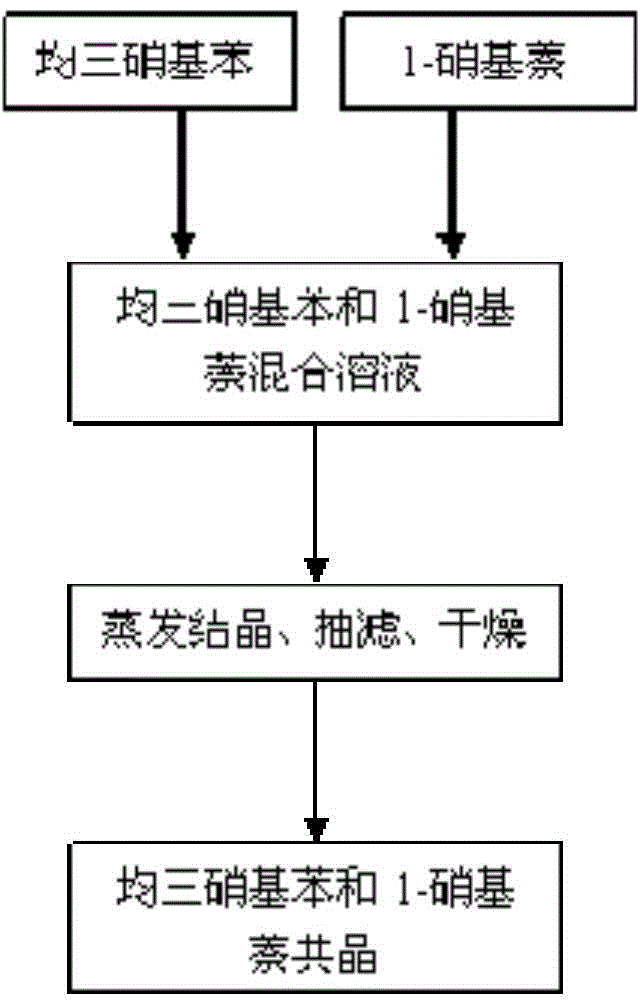

Eutectic explosive containing trinitrobenzene and 1-nitronaphthalene and preparing method of eutectic explosive

InactiveCN104926573AEasy to operateSuitable for large-scale industrial productionNitrated aromatic explosive compositionsExplosive working-up apparatusBenzeneEvaporation

The invention discloses a eutectic explosive containing trinitrobenzene and 1-nitronaphthalene and a preparing method of the eutectic explosive, and belongs to the technical field of explosive eutectic. The trinitrobenzene and the 1-nitronaphthalene are bonded in a crystal of the same crystal lattice through the intermolecular force by adopting an evaporation solvent method or a suspension method. The thermal stability of the prepared eutectic explosive is greatly improved, the eutectic sensitivity is greatly reduced compared with that of a single-compound explosive, the eutectic melting point is lower than 100 DEG C, and the eutectic explosive can be used as a casting explosive component.

Owner:NANJING UNIV OF SCI & TECH

Methods of producing 1,3,5-triamino-2,4,6-trinitrobenzene

Methods of producing TATB are disclosed. The method comprises providing acid wet TNPG and distilling water from the acid wet TNPG. The TNPG is reacted with an alkoxylating agent to form a solution of 1,3,5-trialkoxy-2,4,6-trinitrobenzene solution, which is reacted with an aminating agent. An alternate method comprises nitrating phloroglucinol in a first vessel to produce TNPG, which is reacted with an alkoxylating agent in a second vessel to form a solution comprising 1,3,5-trialkoxy-2,4,6-trinitrobenzene and at least one of at least one volatile byproduct and at least one nonvolatile byproduct. The at least one of at least one volatile byproduct and at least one nonvolatile byproduct is removed in situ. The 1,3,5-trialkoxy-2,4,6-trinitrobenzene is reacted with an aminating agent.

Owner:NORTHROP GRUMMAN SYST CORP

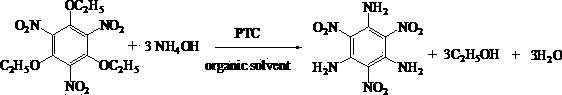

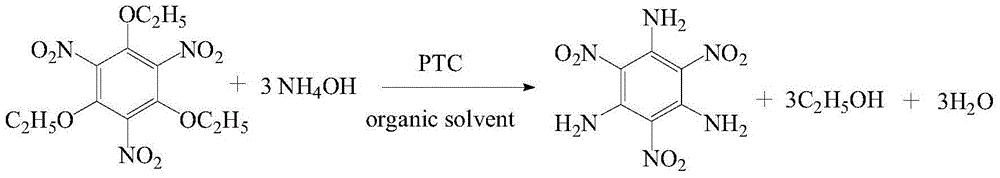

Method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination

ActiveCN103408435ASolving Chlorine ProblemsReduce usageOrganic compound preparationAmino compound preparationSynthesis methodsEthyl Chloride

The invention discloses a method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination. The method comprises the following steps: 1, adding 1,3,5-triethoxy-2,4,6-triaminobenzene, an organic solvent and a phase-transfer catalyst into a reactor, raising temperature and stirring, and dropwise adding ammonium hydroxide to carry out a reflux reaction; 2, after the reaction is ended, and separating a product and mother liquor, wherein the product is washed and dried to obtain TATB; and 3, analyzing and calibrating the mother liquor so as to be recycled and reused. Compared with the prior art, the method disclosed by the invention has the remarkable advantages that (1) the product TATB does not contain chlorine element, so that the chlorine-containing problem in a traditional synthesis method is solved; (2) the purity of the prepared TATB product which is not subjected to purification treatment can reach more than 98.0 percent; (3) reaction conditions are mild, the reaction operation is simple, and as the TATB is synthesized in a normal temperature phase-transfer catalysis and amination system, an airtight high pressure reaction kettle is not required, and industrial large-scale production is facilitated.

Owner:NANJING UNIV OF SCI & TECH

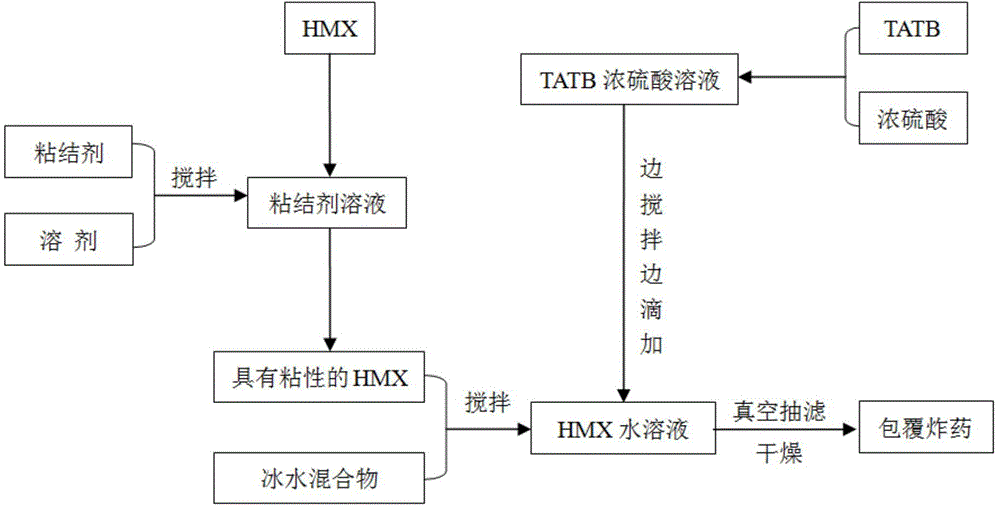

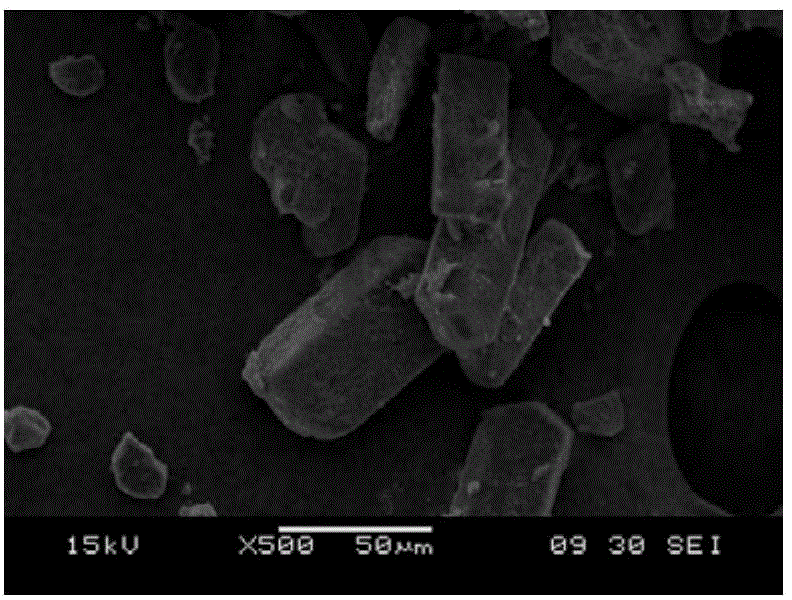

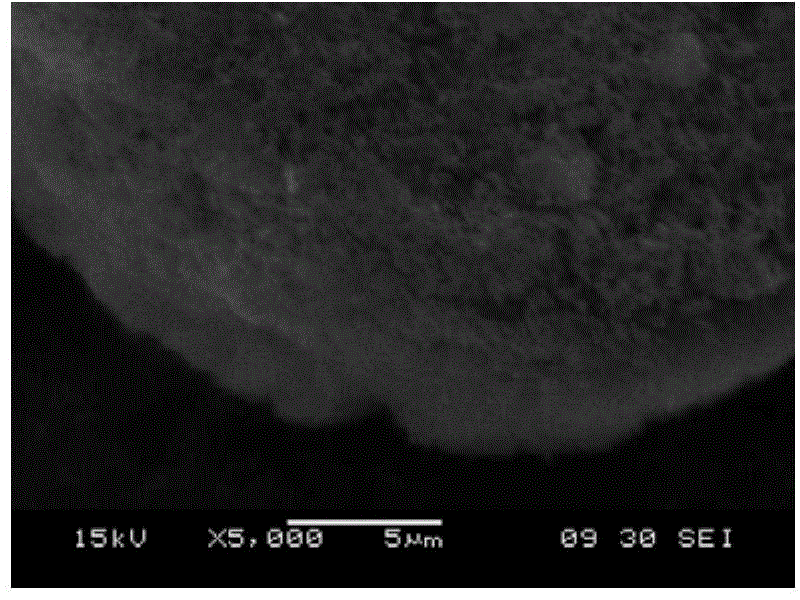

Method for coating and sensitivity reduction of HMX by using TATB

InactiveCN105985206AGood coating effectStop sheddingNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsIce waterSolvent

The invention discloses a method for coating desensitizing HMX with TATB, comprising the following steps: adding binder, solvent and HMX into a beaker, heating and stirring until dissolved evenly, and then vacuum filtering and drying to obtain surface active and cohesive HMX; TATB was dissolved in concentrated sulfuric acid and stirred until dissolved to obtain a mixed solution of TATB concentrated sulfuric acid; the prepared surface-active and cohesive HMX and ice-water mixture were added to a four-necked flask, and TATB The mixed solution of concentrated sulfuric acid was slowly dropped into the four-neck flask through the constant pressure dropping funnel, and the suspension was obtained by rapid stirring while dropping; the obtained suspension was vacuum filtered, and the filter cake was washed with detergent until the pH value of the filtrate was close to neutral. , and dried to obtain TATB-coated HMX mixed explosives. The method of the invention uses concentrated sulfuric acid as a solvent to refine TATB to directly form a coating layer on the surface of HMX, and uses a binder in the coating process to effectively prevent the falling off of TATB, with mild reaction conditions and simple reaction operation.

Owner:NANJING UNIV OF SCI & TECH

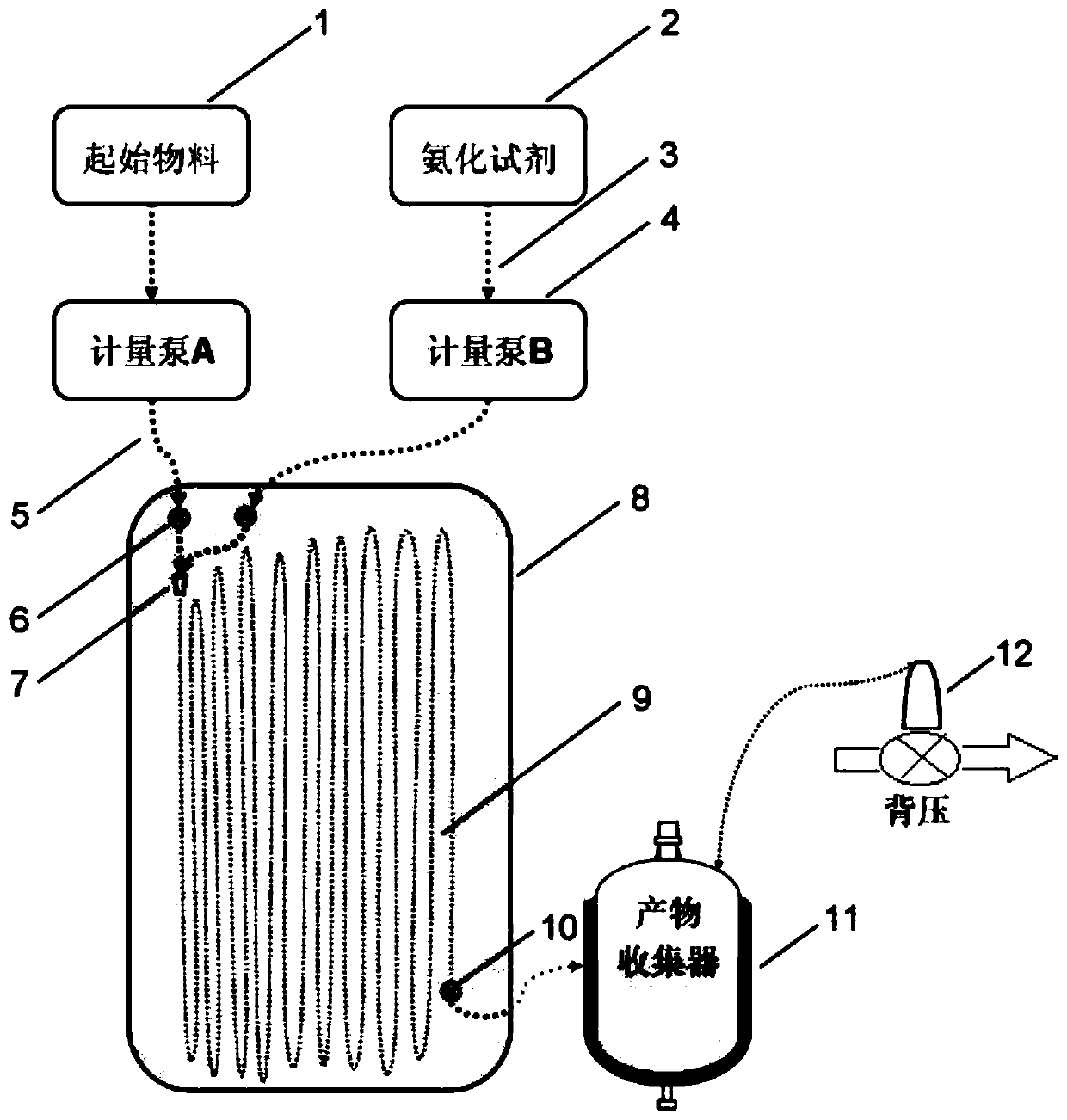

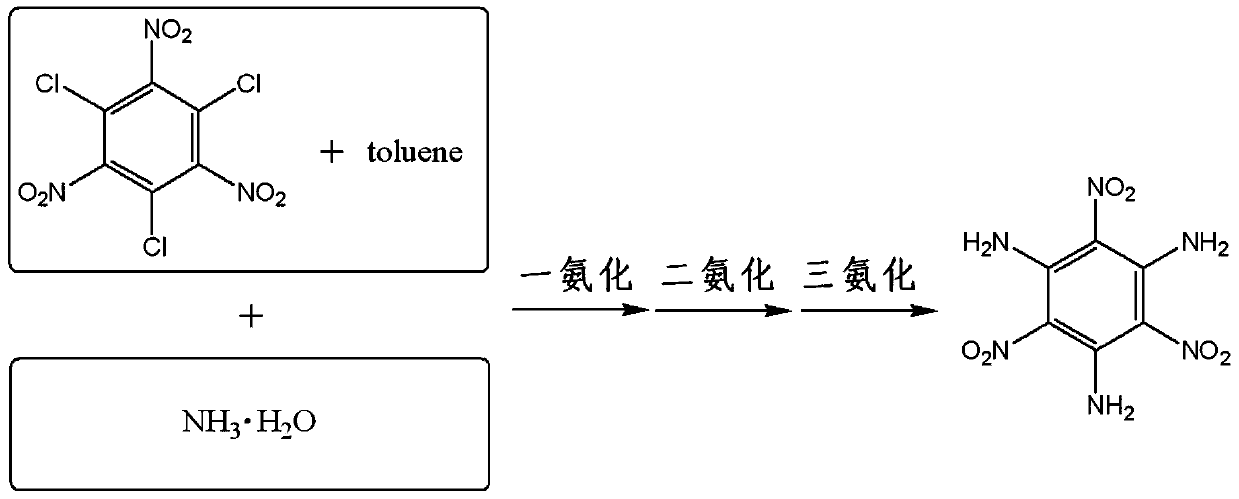

Channel synthesis method of m-triamino trinitrobenzene

ActiveCN109824521AHas explosive propertiesFlammable and explosiveOrganic compound preparationAmino compound preparationRetention timeSynthesis methods

The invention discloses a channel synthesis method of m-triamino trinitrobenzene. The channel synthesis method of m-triamino trinitrobenzene comprises following steps: 1, a toluene solution of m-trichloro trinitrobenzene is prepared as an initial material; 2, an ammonification reagent is prepared; 3, the initial material and the ammonification reagent are pumped into a channel type reactor throughtwo inlets of the channel type reactor using metering pumps synchronously; 4, the initial material and the ammonification reagent are mixed and reacted in the channel type reactor, wherein reaction time retention time is controlled to be 10 to 1000s; 5, an obtained reaction product is delivered into a collector through a reaction channel, thermal insulation reaction is carried out for 0 to 10h, and mother liquor filtering, filter cake washing and drying are carried out based on routine methods so as to obtain a target product. According to the channel synthesis method, utilization of the highefficiency heat and mass transfer capacity of the channel type reactor is adopted to realize synthesis technology accurate control, parameter fluctuation is reduced, conversion rate is close to 100%under optimized conditions, the particle size of the obtained m-triamino trinitrobenzene product ranges from 10 to 60<mu>m, and the peak value particle size ranges from 15 to 30<mu>m.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for grafting energetic macromolecules on surface of 1,3,5-triamido-1,3,5-trinitrobenzene crystal powder

The invention discloses a method for grafting energetic macromolecules on the surface of 1,3,5-triamido-1,3,5-trinitrobenzene crystal powder. The method comprises the following steps: (1) adding 1,3,5-triamido-1,3,5-trinitrobenzene explosive crystal powder into a dopamine water solution for mechanical stirring, carrying out suction filtration, and drying with inert gas; (2) adding the explosive crystal powder into butyl acetate for mechanical stirring dispersion, then adding toluene diisocynate and dibutyltin dilaurate, carrying out backflow suction filtration, and washing with butyl acetate for three to five times; and (3) adding the explosive crystal powder into butyl acetate for mechanical stirring dispersion, then adding glycidyl azide polymer and dibutyltin dilaurate, carrying out backflow suction filtration, and washing with butyl acetate for three to five times, and carrying out vacuum drying. The invention provides a simple and efficient explosive crystal surface modification new technique, and technical support can be provided for the application of explosive crystals in compound explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for synthesizing 3,5-dichloroanisole from 1,3,5-trichlorobenzene

ActiveUS20130178655A1Organic compound preparationAmino compound preparationAlkaline earth metalMetal

The invention relates to a method for synthesizing 3,5-dichloroanisole from 1,3,5-trichlorobenzene, which comprises:a) the reaction between 1,3,5-trichlorobenzene and a methanolate of an alkaline or alkaline-earth metal in a first solvent chosen from among dimethylsulfoxide and 1,1,3,3-tetramethylurea;b) the precipitation of the product resulting from step a) in a second solvent which is not included among substances considered carcinogenic, mutagenic and / or toxic for reproduction by Regulation (EC) n° 1272 / 2008 of the European Parliament and of the Council of 16 Dec. 2008; thenc) the recovery of the precipitate thus obtained.Application: synthesis of 1,3,5-triamino-2,4,6-trinitrobenzene of which 3,5-dichloroanisole is an intermediate product.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

2, 4, 4'-trinitrobenzene formanilide preparation method

ActiveCN102633674AImprove protectionHigh yieldOrganic compound preparationCarboxylic acid amides preparationMolten stateDistillation

The invention discloses a 2, 4, 4'-trinitrobenzene formanilide preparation method, which includes the steps: firstly, adding 2, 4-dinitroaniline and paranitrobenzoyl chloride into a reaction device in a nitrogen atmosphere, stirring and increasing the temperature to 178-185 DEG C for reaction of 10h-15h, wherein the molar ratio of the 2, 4-dinitroaniline to paranitrobenzoyl chloride is 1:1.1-1:1.5; secondly, increasing the temperature to 195-200 DEG C, and distilling to recover unreacted paranitrobenzoyl chloride; and thirdly, cooling to 140-150 DEG C, so that 2, 4, 4'-trinitrobenzene formanilide is obtained by means of reduced pressure distillation. By the method, the reaction temperature can be controlled to be higher than the melting points of the two kinds of raw materials, so that condensation reaction can be performed in the molten state, solvent is not needed, environmental protection is benefited, yield is greatly increased, and the method is suitable for large-scale industrial production.

Owner:大连新阳光材料科技有限公司 +1

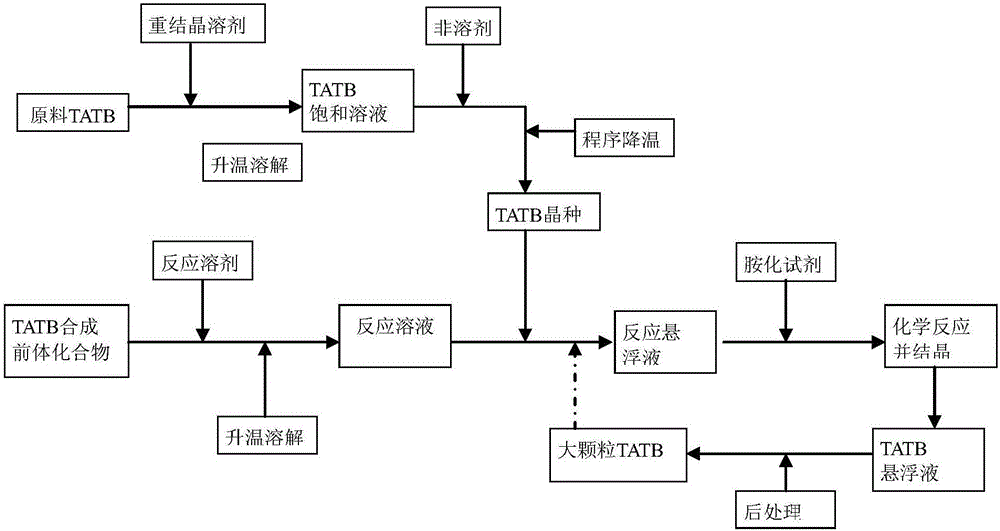

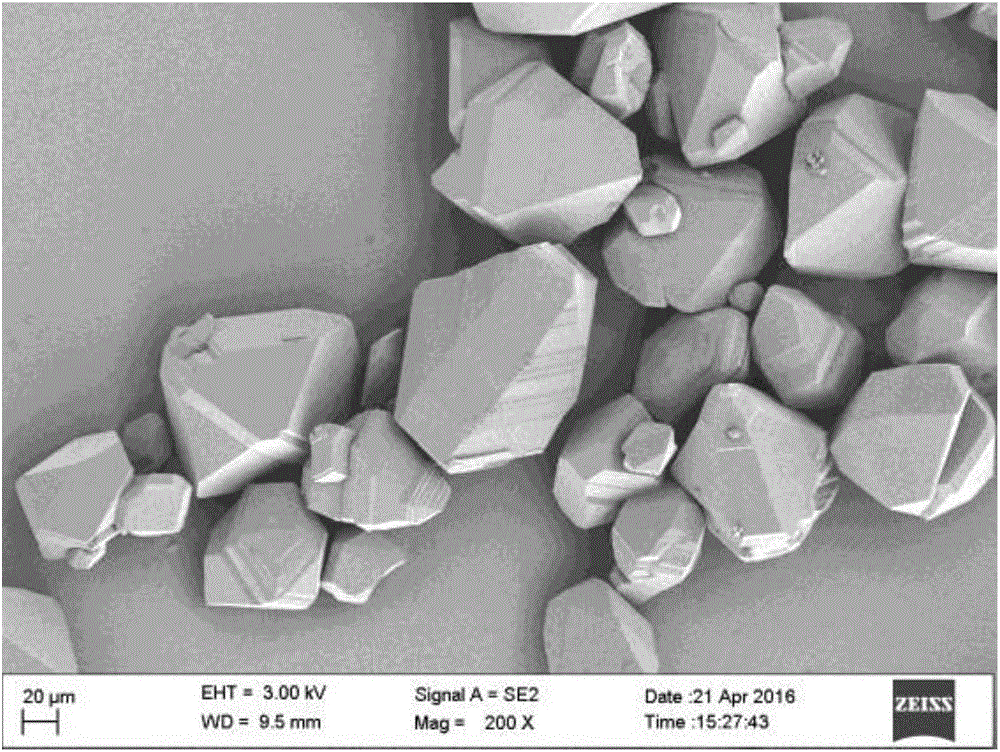

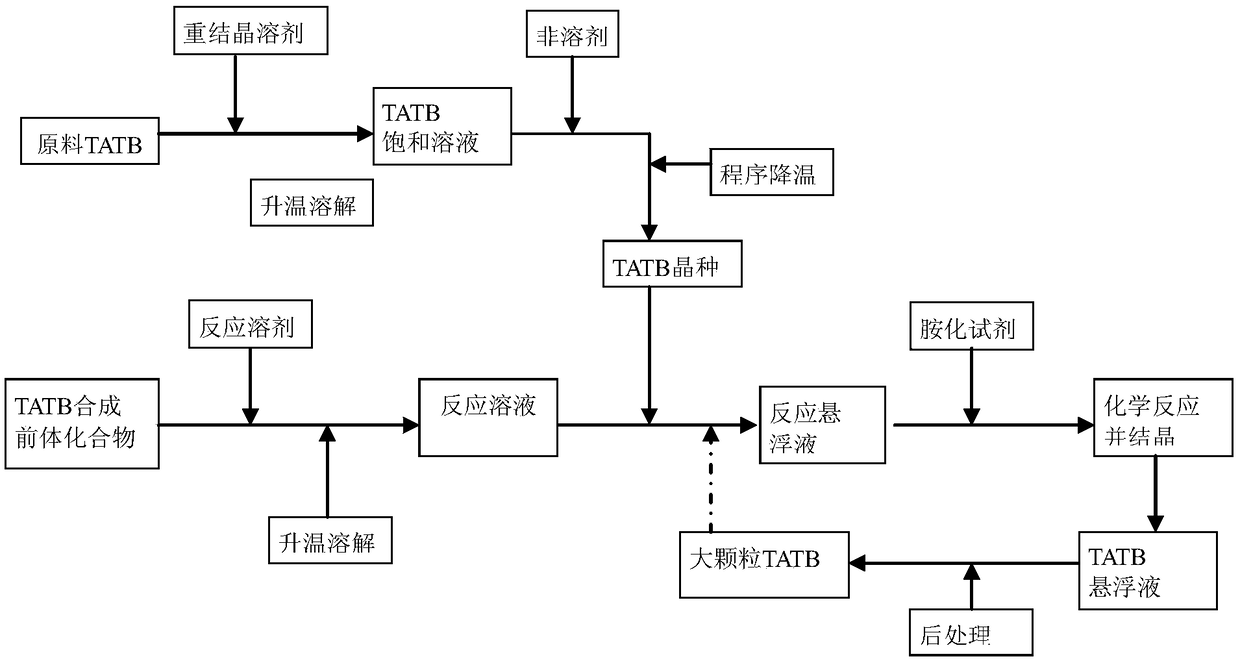

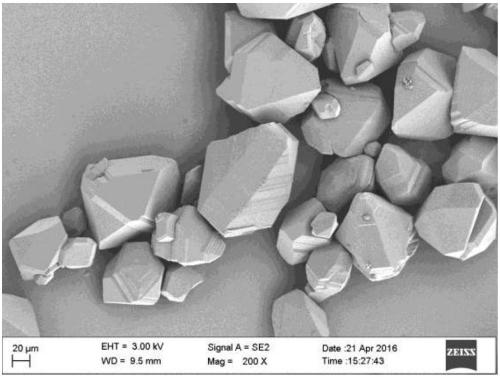

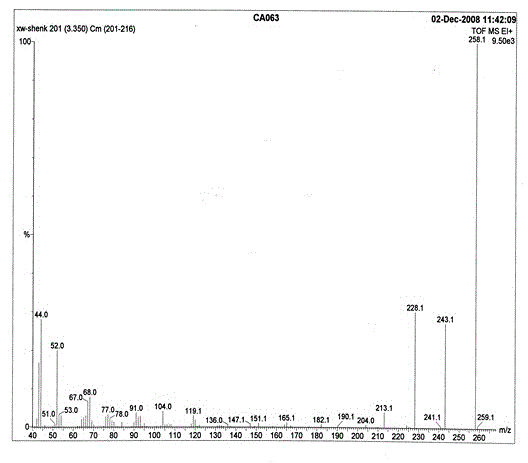

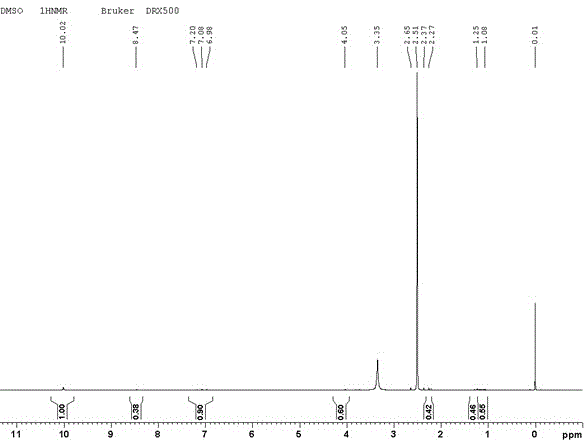

Method for preparing large-grained triamino trinitrobenzene by reactive crystallization method

ActiveCN106496043AImproved anisotropic expansionNo pollutionAmino compound purification/separationOrganic compound preparationTemperature controlTATB

The invention discloses a method for preparing large-grained triamino trinitrobenzene (TATB) by a reactive crystallization method. The method comprises the steps: adding common TATB into a recrystallization solvent, increasing temperature and dissolving to obtain a saturated solution, adding an anti-solvent, cooling to room temperature according to a temperature control program and crystallizing to obtain TATB crystal grains to serve as seed crystals; and dissolving a precursor compound for synthesizing the TATB into a reaction solvent at room temperature, increasing temperature, promoting dissolution of the compound, adding the TATB seed crystals, adding an aminating reagent under the stirring condition, reacting at a certain temperature to crystallize, cooling to room temperature and performing aftertratment to obtain the large-grained TATB. The method is simple in process, convenient in operation, high in safety and easy in engineering enlargement. The large-grained TATB prepared by the method can be used for pouring and press-fitting charge, the charge solid content is obviously improved, the charge free-flowing property is improved, and the anisotropic expansion and the dimensional stability of TATB based explosive can be improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Manufacturing process of ACE active peptide for reducing blood fat

InactiveCN108949727ALow impurity contentHigh purityMetabolism disorderPeptidasesWater bathsHydrolysate

The invention discloses a manufacturing process of an ACE (angiotensin converting enzyme) active peptide for reducing blood fat. The manufacturing process comprises the following steps: (S1) extracting a raw material protein, and denaturing the raw material protein through strong acid; (S2) repeatedly flushing precipitates through clean water; (S3) adding trinitrobenzene sulfonic acid with a concentration of 4%-6% into the precipitates, so as to obtain a peptide solution; (S4) putting the peptide solution into water at 85-100 DEG C, and carrying out water-bath enzyme deactivation; and (S5) centrifuging a mixed solution A by virtue of a centrifugal machine, and carrying out ultrafiltration, so as to obtain clear hydrolysate; (S6) adding a discoloration and odor-removal agent into hydrolysate, and stirring by virtue of a stirring machine, so as to obtain a primary peptide solution; (S7) enabling the primary peptide solution to flow through anion and cation exchange resin for primarily desalination, so as to obtain a fine peptide solution; (S8) carrying out vacuum drying on the fine peptide solution, so as to obtain a finished product; and (S9) detecting the purity of the active peptide in the finished product by virtue of a liquid chromatographic analysis method, so as to obtain the high-purity ACE active peptide.

Owner:ANHUI SHUNXIN SHENGYUAN BIOLOGICAL FOOD CO LTD

Explosive for chemical-defense canister shot and preparation method of explosive

ActiveCN106397073AUniform particle sizeHigh charge densityExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsEngineeringGraphite

The invention provides an explosive for a chemical-defense canister shot. The explosive for the chemical-defense canister shot is prepared from 39.00wt% to 48.95wt% of 1,3,5-triamino-2,4,6-trinitrobenzene, 48.75wt% to 58.74wt% of cyclotrimethylene trinitramine, 2.00wt% to 2.30wt% of polymethyl acrylate-butyl acrylate-vinyl acetate polymer and 0.10wt% to 0.20wt% of graphite. The explosive provided by the invention is high in charging density, low in mechanical sensitivity and moderate in detonation velocity and force; the use requirement of charging the explosive for the chemical-defense canister shot can be met. In addition, the invention provides a preparation method of the explosive for the chemical-defense canister shot; the operation is simple and convenient; the preparation method is applicable to industrial production.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

Explosive for anti-chemical submunition and preparation method thereof

ActiveCN106397073BLow priceEasy to operateExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsGraphiteChemical defense

The invention provides an explosive for a chemical-defense canister shot. The explosive for the chemical-defense canister shot is prepared from 39.00wt% to 48.95wt% of 1,3,5-triamino-2,4,6-trinitrobenzene, 48.75wt% to 58.74wt% of cyclotrimethylene trinitramine, 2.00wt% to 2.30wt% of polymethyl acrylate-butyl acrylate-vinyl acetate polymer and 0.10wt% to 0.20wt% of graphite. The explosive provided by the invention is high in charging density, low in mechanical sensitivity and moderate in detonation velocity and force; the use requirement of charging the explosive for the chemical-defense canister shot can be met. In addition, the invention provides a preparation method of the explosive for the chemical-defense canister shot; the operation is simple and convenient; the preparation method is applicable to industrial production.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

2, 4, 4'-trinitrobenzene formanilide preparation method

ActiveCN102633674BImprove protectionHigh yieldOrganic compound preparationCarboxylic acid amides preparationMolten stateDistillation

The invention discloses a 2, 4, 4'-trinitrobenzene formanilide preparation method, which includes the steps: firstly, adding 2, 4-dinitroaniline and paranitrobenzoyl chloride into a reaction device in a nitrogen atmosphere, stirring and increasing the temperature to 178-185 DEG C for reaction of 10h-15h, wherein the molar ratio of the 2, 4-dinitroaniline to paranitrobenzoyl chloride is 1:1.1-1:1.5; secondly, increasing the temperature to 195-200 DEG C, and distilling to recover unreacted paranitrobenzoyl chloride; and thirdly, cooling to 140-150 DEG C, so that 2, 4, 4'-trinitrobenzene formanilide is obtained by means of reduced pressure distillation. By the method, the reaction temperature can be controlled to be higher than the melting points of the two kinds of raw materials, so that condensation reaction can be performed in the molten state, solvent is not needed, environmental protection is benefited, yield is greatly increased, and the method is suitable for large-scale industrial production.

Owner:大连新阳光材料科技有限公司 +1

Method for preparing large particle triaminotrinitrobenzene by reaction crystallization method

ActiveCN106496043BImproved anisotropic expansionNo pollutionAmino compound purification/separationOrganic compound preparationDissolutionSeed crystal

The invention discloses a method for preparing large-grained triamino trinitrobenzene (TATB) by a reactive crystallization method. The method comprises the steps: adding common TATB into a recrystallization solvent, increasing temperature and dissolving to obtain a saturated solution, adding an anti-solvent, cooling to room temperature according to a temperature control program and crystallizing to obtain TATB crystal grains to serve as seed crystals; and dissolving a precursor compound for synthesizing the TATB into a reaction solvent at room temperature, increasing temperature, promoting dissolution of the compound, adding the TATB seed crystals, adding an aminating reagent under the stirring condition, reacting at a certain temperature to crystallize, cooling to room temperature and performing aftertratment to obtain the large-grained TATB. The method is simple in process, convenient in operation, high in safety and easy in engineering enlargement. The large-grained TATB prepared by the method can be used for pouring and press-fitting charge, the charge solid content is obviously improved, the charge free-flowing property is improved, and the anisotropic expansion and the dimensional stability of TATB based explosive can be improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination

ActiveCN103408435BSolving Chlorine ProblemsReduce usageOrganic compound preparationAmino compound preparationOrganic solventTATB

The invention discloses a method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination. The method comprises the following steps: 1, adding 1,3,5-triethoxy-2,4,6-triaminobenzene, an organic solvent and a phase-transfer catalyst into a reactor, raising temperature and stirring, and dropwise adding ammonium hydroxide to carry out a reflux reaction; 2, after the reaction is ended, and separating a product and mother liquor, wherein the product is washed and dried to obtain TATB; and 3, analyzing and calibrating the mother liquor so as to be recycled and reused. Compared with the prior art, the method disclosed by the invention has the remarkable advantages that (1) the product TATB does not contain chlorine element, so that the chlorine-containing problem in a traditional synthesis method is solved; (2) the purity of the prepared TATB product which is not subjected to purification treatment can reach more than 98.0 percent; (3) reaction conditions are mild, the reaction operation is simple, and as the TATB is synthesized in a normal temperature phase-transfer catalysis and amination system, an airtight high pressure reaction kettle is not required, and industrial large-scale production is facilitated.

Owner:NANJING UNIV OF SCI & TECH

Photosensitive polymer material

The invention relates to a photosensitive polymer material. Particularly, the photosensitive polymer material is prepared from, by weight, 100 parts of polyvinyl cinnamate resin, 4-6 parts of 2,4,6-trinitrobenzene, 2-5 parts of ferrofluorophosphate, 0.1-0.5 part of 1,4-naphthoquinone and 1-5 parts of dimethicone. The photosensitive polymer material is excellent in stable performance, can sense light for a long time, the initial light sensing effect of the photosensitive polymer material is kept, the heat resistance, weather resistance and other performances are remarkably improved, the production technology is simple and easy to implement, and the photosensitive polymer material is suitable for industrial large-scale production.

Owner:吴中区穹窿山师匠新材料技术咨询服务部

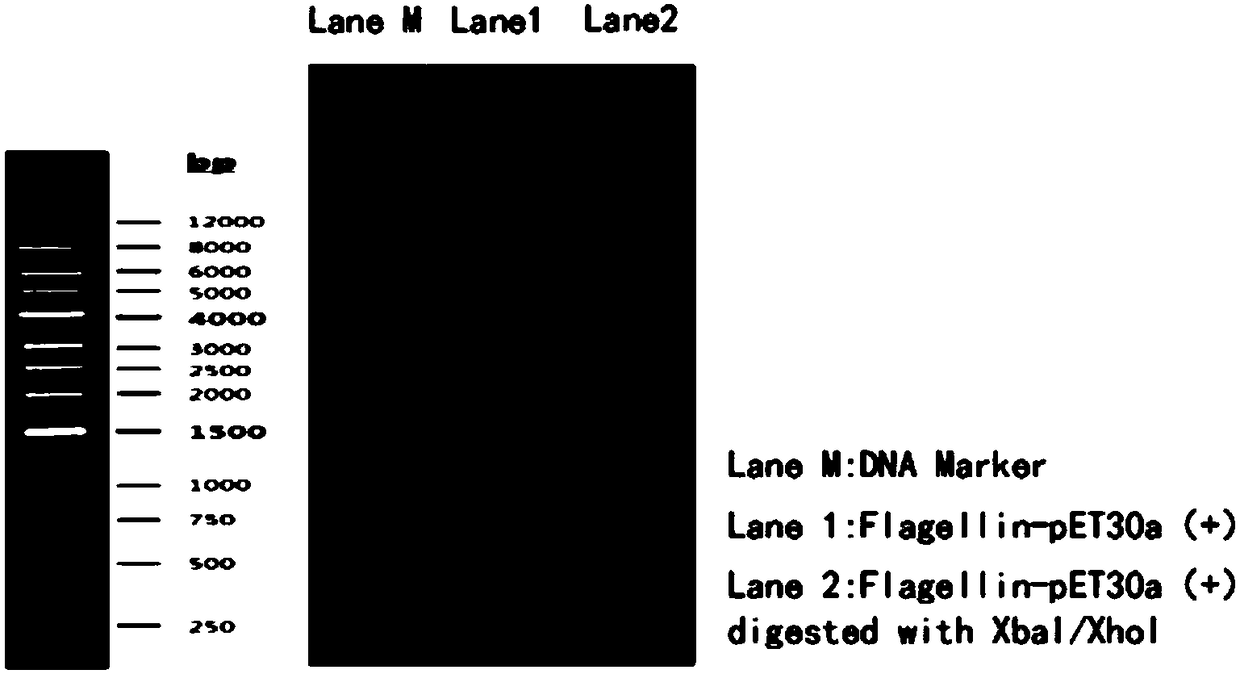

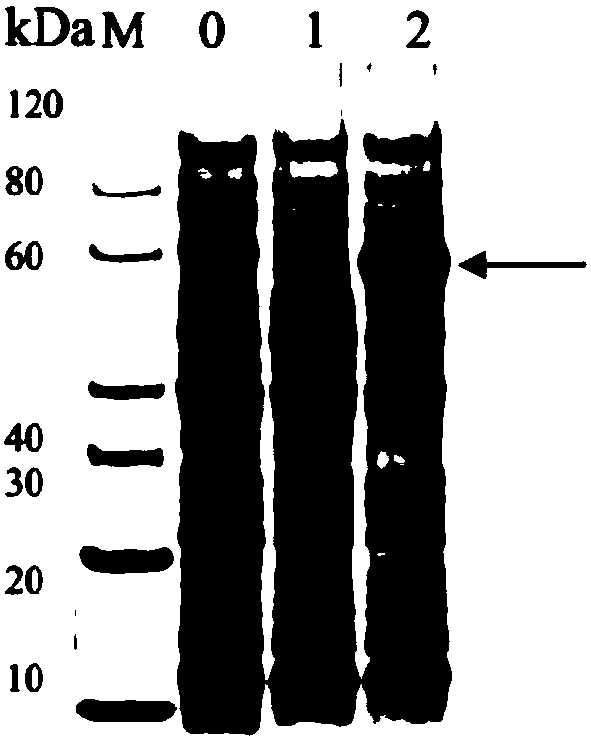

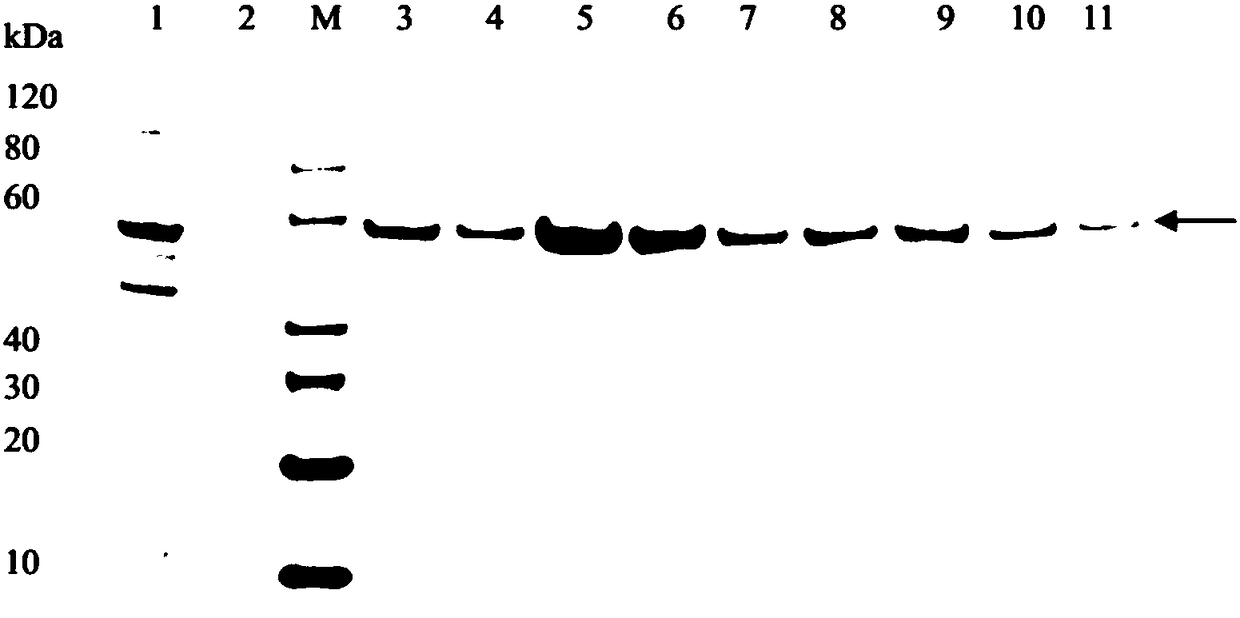

Application of intestinal rothia recombinant flagellin to preparation of medicine for preventing and treating inflammatory bowel diseases

InactiveCN108159397ADecreased food/water intakeReduced activityPeptide/protein ingredientsDigestive systemTherapeutic effectFlagellin

The invention discloses application of intestinal rothia recombinant flagellin to the preparation of a medicine for preventing and treating inflammatory bowel diseases. The name of the intestinal rothia recombinant flagellin is RI-flagellin, and the intestinal rothia recombinant flagellin comprises His tag protein and fused protein of amino acid residues at a 1st site to a 497th site from an N endof the intestinal rothia recombinant flagellin. The invention provides application of the RI-flagellin to research and development of medicines for the inflammatory bowel diseases; an experiment of carrying out coloclysis on a mouse by utilizing 2,4,6-trinitrobenzene sulfonic acid (TNBS) to simulate the inflammatory bowel diseases finds out that the RI-flagellin has a remarkable prevention and treatment effect on the inflammatory bowel diseases. The intestinal rothia recombinant flagellin RI-flagellin can be used as an active component to prepare the medicine for preventing and treating the inflammatory bowel diseases.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

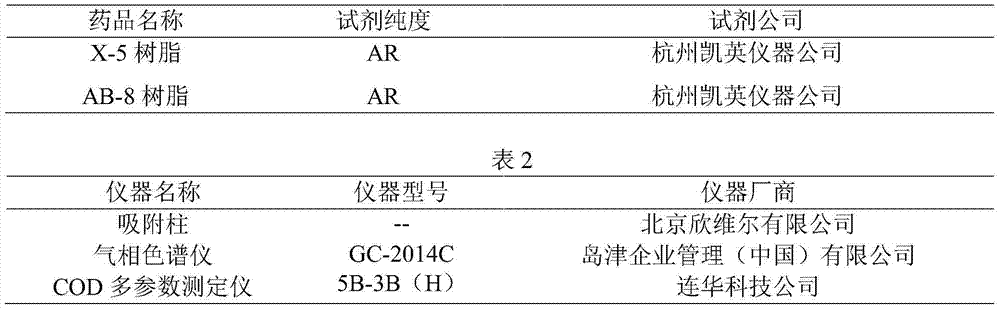

Treatment method of nitration wastewater in TATB (triamino trinitrobenzene) production technique

InactiveCN104261503AImprove adsorption capacityHigh removal rateNature of treatment waterWater/sewage treatment by sorptionTreatment effectDesorption

The invention discloses a treatment method of nitration wastewater in a TATB (triamino trinitrobenzene) production technique, belonging to the technical field of wastewater treatment by chemical techniques. The method comprises the following steps: filtering wastewater generated by TATB nitration, collecting the precipitate, and washing to obtain nitration wastewater; adding the nitration wastewater into an adsorption column filled with an ultrahighly-crosslinked adsorbent resin to adsorb phenol compounds in the wastewater onto the resin and obtain an effluent liquid, wherein the effluent liquid is treated nitration wastewater; and carrying out desorption treatment on the ultrahighly-crosslinked adsorbent resin for cyclic utilization. The treatment method of nitration wastewater implements cyclic utilization of 2,4,6-trinitrophloroglucin and acid liquor on the premise of enhancing the wastewater treatment effect, reduces the pollution, lowers the cost, and implements organic combination of wastewater treatment and resource recovery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com